|

|

Post by evergreen on Apr 20, 2008 9:40:09 GMT

I recently acquired a fascinating little book called Elementary Carpentry and Joinery published in the late 19th century for "all amateur artisans and mechanics at home and abroad". The following passage caught my eye:  The book is too frail to scan - hope you can read it OK. It shows that a) honing guides existed in Victorian times and b) amateurs were being urged NOT to use them because professionals didn't use them! Some things never change! The next section of the book goes on to describe how some folk soak blades in "muriatic acid" to soften them before sharpening although this isn't recommended... Regards |

|

|

|

Post by engineerone on Apr 20, 2008 10:56:10 GMT

oh no, now jacob has printed justification for his method, since it is over a hundred years old ;D  it also proves you have to learn to read to know things  paul  |

|

|

|

Post by evergreen on Apr 20, 2008 14:32:05 GMT

Paul

I think Jacob may be the author of the book! I couldn't find a name in it anywhere but the style is familiar.....

Regards.

|

|

|

|

Post by mrgrimsdale on Apr 20, 2008 14:45:13 GMT

There you go then - I knew I was right ;D NB and there's a lot of us - I'm not the only one  Corks and bladders- very apt. Nothing changes - tool dealers even 100 years ago were feverishly inventing completely useless gadgets to sell to the unwary. I just spotted another one in the Rutlands catalogue - a door stand. Nowhere near as as good as this below, which is free, knocked up from scraps in minutes, has a much larger bearing area and so won't mark the wood surface, can be nailed/screwed to saw horses for edge planing boards on site etc   |

|

|

|

Post by mrspanton on Apr 21, 2008 20:40:54 GMT

George ellises book has lots of those useFUL sort of simple home made devices aparently they chopped mortices on stubby low stool's not benches

|

|

|

|

Post by paulchapman on Apr 21, 2008 20:49:07 GMT

aparently they chopped mortices on stubby low stool's not benches But people were shorter in those days ;D |

|

|

|

Post by engineerone on Apr 21, 2008 21:21:01 GMT

actually paul i think that it was because there were more people in the workshop, and more work waiting through glue up, so space was restricted. in addition in many trades the "hop up" or stool were the preferred place to work. i know some of this info in my case comes from a stone mason's shop, but it does apply across a number of other manual trades, including many metal working ones. ;D paul  |

|

|

|

Post by mrgrimsdale on Apr 22, 2008 7:05:36 GMT

Would it have been a shaving horse type stool (without the top hamper)? Just the thing for morticing. You'd sit astride it on top of the workpiece with the mortice just in front of you. We used to have a similar "pig bench" in our kitchen which was useful for jobs like shelling peas, peeling taters, kneading bread. Sit astride with the bowl of stuff in front of you. A comfortable and practical working position. Might try it again next time I'm morticing peas etc. cheers Jacob |

|

|

|

Post by mrspanton on Apr 22, 2008 20:34:31 GMT

No it wasnt even that inticate

Just a 4x2 on its side with 2 4x2 legs attached either end with bridle joints, the legs only look to be 10 or 12 inche's hoigh they used a wooden bolster to blow waste out

I often cut mortices outdoor's I sit on the beam and it rest's on two saw horses with the mortice directly above one of the horses

|

|

|

|

Post by wrongnail on Apr 23, 2008 10:30:11 GMT

There you go then - I knew I was right ;D NB and there's a lot of us - I'm not the only one  Corks and bladders- very apt. Nothing changes - tool dealers even 100 years ago were feverishly inventing completely useless gadgets to sell to the unwary. I just spotted another one in the Rutlands catalogue - a door stand. Nowhere near as as good as this below, which is free, knocked up from scraps in minutes, has a much larger bearing area and so won't mark the wood surface, can be nailed/screwed to saw horses for edge planing boards on site etc   I have seen this arrangement (A common one on most sites I worked on) offered to a woodwork magazine as a tip. What's more, it won the prize..  It's certainly usefuil around the home, where there ain't much room! |

|

|

|

Post by andy on Apr 23, 2008 11:56:29 GMT

I have seen this arrangement (A common one on most sites I worked on) offered to a woodwork magazine as a tip. What's more, it won the prize..  I hope it was not in British Woodworking  |

|

|

|

Post by mrgrimsdale on Apr 23, 2008 18:32:20 GMT

Wouldn't be surprised I bet they'd never have seen one. ;D

It was my mate Gavin who showed it to me.

cheers

Jacob

|

|

|

|

Post by modernist on Apr 27, 2008 21:04:20 GMT

The clamp is commonly used in the States I believe for a multitude of work clamping and was recently featured in FW for testing chain morticers.

Not a bad idea though

Brian

|

|

|

|

Post by mrgrimsdale on May 3, 2008 17:00:28 GMT

The clamp is commonly used in the States I believe for a multitude of work clamping and was recently featured in FW for testing chain morticers. Not a bad idea though Brian Is a damn good idea! Very basic bit of essential kit. I got a copy of evergreens "Elementary Carpentry and Joinery". Abe books - brilliant. Its a nice book. It shows wedge clamps as an alternative to a screw vice on a work bench. Very clever. Vaguely similar to the Chris Schwarz illustrated "crochet" but adjustable, plus wedge for firm grip. I'll scan the picture when i've got a mo. cheers Jacob |

|

|

|

Post by modernist on May 3, 2008 22:15:07 GMT

It shows wedge clamps as an alternative to a screw vice on a work bench. Very clever. Vaguely similar to the Chris Schwarz illustrated "crochet" but adjustable, plus wedge for firm grip. I'll scan the picture when i've got a mo. cheers Jacob The wedge is a grossly under-rated device for clamping. In my other life as a mechanical engineer working in the quarrying industry I am constantly plagued by the use of threaded fasteners (bolts and nuts) in very dusty environments which duly jam up, sometimes to the point of shear, especially if stainless. (RR in Derby ended up silver plating their stainless bolts for this reason). Cross the Channel to Germany and most unstressed items such as covers on conveyors etc are attached with captive wedges which can be released with the redoubtable lump hammer, irrespective of the amount of dust, and lot quicker too! Brian |

|

|

|

Post by engineerone on May 3, 2008 22:30:37 GMT

i too agree that wedges are under used. i wonder how much is due to the lack of actual experience and knowledge. for instance i saw tommy walsh putting some folding wedges in a door/stud frame a couple of days ago, but what no one actually tells you is the kind of angles you should use, and whether there are specifics in different usages. i know i used to use them on milling machines when holding down parts to be machined. and of course we have all looked at using hold downs which are a different type of wedge. paul  |

|

|

|

Post by paulchapman on May 4, 2008 8:31:12 GMT

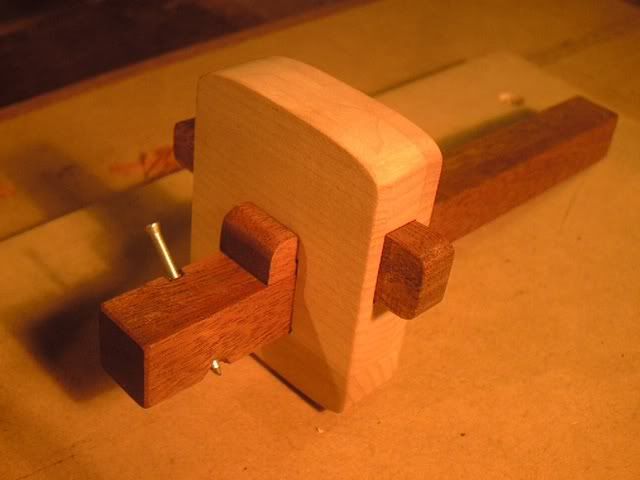

but what no one actually tells you is the kind of angles you should use There was a good discussion on this subject over on the other side a long time ago on the subject of wedges for tools like marking gauges. What turned out to be best was a quite shallow angle of about 5 degrees. I used something like that when making this marking gauge and also used a saddle to spread the pressure (pinched that idea from Rob Stoakley, who pinched it from an old gauge he saw in Pennyfarthing Tools). Works really well   Cheers  Paul |

|