mono

New Member

Posts: 8

|

Post by mono on May 5, 2008 9:12:46 GMT

Hi All,

I have an old 3 phase cooksley 12" planer/thicknesser and wonder if anyone can point me in direction to get a manual for same...

Thanks

Mono

|

|

|

|

Post by Scrit on May 5, 2008 10:56:58 GMT

Hello and welcome!

I'm afraid that Cooksley has long gone the way of the world. Their last factory unit, near Kingston-on-Thames, closed down in the mid-1980s and was redeveloped for housing, but the firm, which was never a big one, had been in decline for many years and the last Cooksley product was a lightweight spindle moulder. I believe that the last planer/thicknessers which they made left the works in the mid to late 1970s, so your machine is probably 30 or more years old. Could you take a look at the specification plate (as Cooksley was in existence for a very long time and made many different designs of machine) and I'll see if I can supply any further information?

Scrit

|

|

mono

New Member

Posts: 8

|

Post by mono on May 6, 2008 10:01:23 GMT

Thanks Scrit,

I'm going to workshop later and will check out plate details.

Have had to dissassemble whole thing basically since, as you can imagine, it is totally gummed up with it seems 30 years of sappy wood.

The pressure bars/feed rollers setups are going to be my primary concern. Greasing the thing is fairly straightforward as I just look for the nipples(!)

While I'm at it I can I prevail upon you for advice on my recently acquired Wadkin 10BRT (72146) ...?

My sliding table falls about 150mm short of cutting a 4 ft board. My suspicion is that I have the sliding rail back to front. Does this sound right or does my machine strangely fall short in this regard?

Thanks

John (mono)

|

|

|

|

Post by Scrit on May 6, 2008 12:18:28 GMT

While I'm at it I can I prevail upon you for advice on my recently acquired Wadkin 10BRT (72146) ...? My sliding table falls about 150mm short of cutting a 4 ft board. My suspicion is that I have the sliding rail back to front. Does this sound right or does my machine strangely fall short in this regard? Yes it does. The BRT was fundamentally a variant of the original AGS table saw with a right hand extension table and a left hand sliding carriage. the carriage has a top surface of 29 x 16in (735 x 405mm) and a cross cut capacity of 39-3/8 x 3-1/8in (1000 x 80mm) or 40-3/8in x 1in (1025 x 25mm) for the 10in BRT250 model, whilst the larger 12in (BRT300) model had capacities of 38-3/8 x 4-1/8in (975 x 105mm) or 39-3/8in x 1in (1000 x 25mm). Whilst Wadkin haven't put the manuals for the BRT on line, you can find the manuals for the 10in AGS here and the 12in AGS here which should be of assistance to you (especially the more detailed 12in manual). In technical terms the biggest difference was the use of a 20 or 25mm saw arbor, although some British BRTs were delivered with a 5/8in arbor. One point to bear in mind is that if you intend to saw large (long) pieces on this saw, especially in crosscut mode, it is best to bolt the machine down to the floor to prevent it from tipping over! Scrit |

|

Telos

Full Member

Posts: 123

|

Post by Telos on May 6, 2008 15:22:52 GMT

As ever... Scrit, the fount of all knowledge...  |

|

mono

New Member

Posts: 8

|

Post by mono on May 6, 2008 20:45:34 GMT

|

|

|

|

Post by Scrit on May 6, 2008 22:06:22 GMT

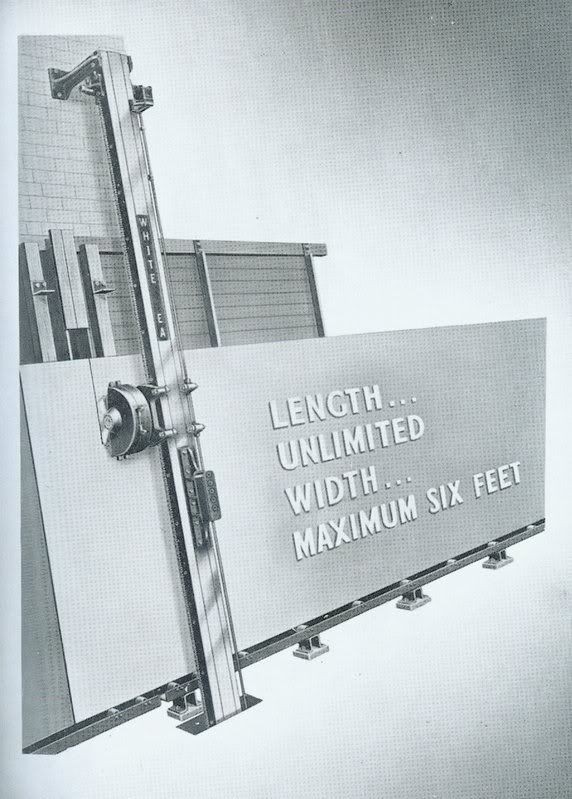

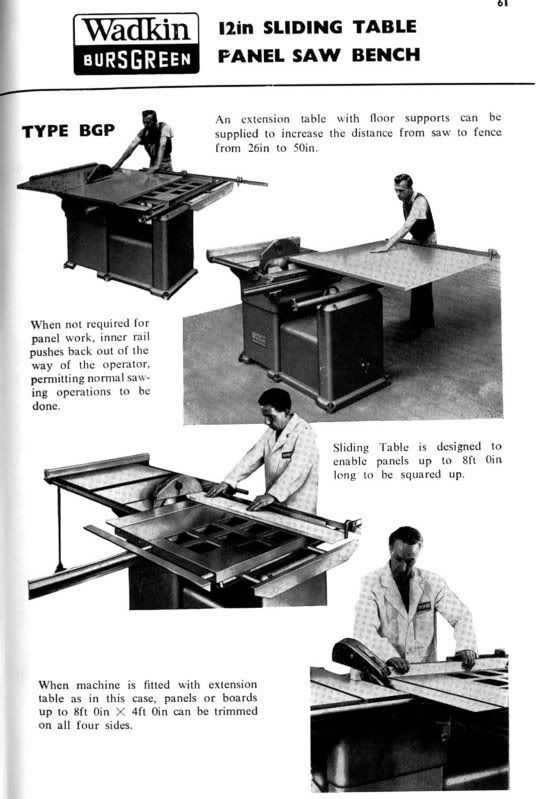

Bizarre that they should make a sliding carriage short of 4ft! Only if you are thinking in current contect. If you realise that this machine was designed something like 40 years ago and in turn was derived from a saw originally produced in 1957 perhaps it makes more sense. To put things in context wall saws first appeared in the early post-WWII years as this Thomas White machine from 1947 shows:  They were used in large factories to break-down plywood and blackboard. In the 1960s larger firms started to use veneered chipboard and MFC and so they started to buy panel saws, like this Wadkin BGP:  These machines had a 4ft cross cut but still couldn't do an 8ft rip. The earliest machines furthermore lacked the all important scoring blade (which appeared in the early to mid 1970s). As you can see the BGP is clearly a relative of the AGS/BRT/BGS designs. Typically at that time small shops would have neither the space nor the money for a proper panel saw and so would do initial breaking-down of sheet stock using a portable Skil saw. That or get the timber merchant to do the job for them. So there was simply no perceived need to have a 4ft cross cut on a table saw. And as I stated earlier, if you loaded an 8 x 4ft sheet onto your BRT it would overbalance unless bolted to the floor....... re: the planer...... It's 3 phase, 2HP and here are some pics from ebay from when I purchased it hope it sheds light.     It's also not a Cooksley! As I mentioned Cooksley were never really a large concern. They were woodworking machinery engineers thus designed and built many machines over the years. They also used to machine castings and do final assembly work for other firms, amongst them Wadkin (on my last visit to the works in 1985 or so there was a row of three brand new Wadkin EQ spindles seemingly being built) as well as acting as agents for several other small manufacturers. Finally they bought, reconditioned and sold second-hand woodworking machines. The Cooksley badge is therefore probably on their because they were acting as a dealer for the manufacturer, Whitehead. Your machine is actually a Whitehead PTJ 12 x 4in planer/thicknesser which Cooksley actively sold into the small workshop and educational markets from the sixties onwards as a lower-cost alternative to their own product (smaller capacity and only one motor, not two). That circle cast on the side will in all probability have the letter "W" cast into it. Incidentally Cooksley also sold Whitehead bandsaws re-branded "Cooksley" (with the upper wheel housing stamped with the Cooksley logoscript and painted in Cooksley colours) in that period, but they were in fact built at Whitehead's in Halifax (another defunct British manufacturer)  For a description of the PTJ take a look at the D.B.Keighley site, here. Keighley wouldn't be a bad place to start looking for spares as they've been going a long time and are less than 15 miles from where the Whitehead machines were made. Scrit PS For anyone interested note the end quadrant mounting of the cast-iron fence and compare that to the rather flimsy arrangement on a Hammer |

|

|

|

Post by gazza on May 6, 2008 22:26:57 GMT

As ever... Scrit, the fount of all knowledge...  Amazing!! Gazza. |

|

mono

New Member

Posts: 8

|

Post by mono on May 6, 2008 23:10:33 GMT

Well, well. Bugger me. I'll be straight in tomorrow with my deerstalker on lookin' for that big W!

Thanks for the research, very much appreciated.

John

|

|

|

|

Post by 9fingers on May 7, 2008 11:41:46 GMT

Well, well. Bugger me. John That's not an option I would relish John but I was pretty sure that Scrit would be able to help you out!! ;D Bob |

|

|

|

Post by Scrit on May 7, 2008 12:38:49 GMT

That's not an option I would relish John but I was pretty sure that Scrit would be able to help you out!! Only with the research, old boy, only with the research.......  |

|

mono

New Member

Posts: 8

|

Post by mono on May 8, 2008 6:49:27 GMT

The Big 'W' on my 'Cooksley' PT has been removed. Thanks again Skrit, great to have info on the providence of the machine. Sort of enriches my relationship with it strangely! Have contacted Keighley as you suggested re manual and spares (which I'll need ideally) but no joy yet. After checking out the price of a new guard and discovering it is 3 1/2 times what I paid for the PT, I have cobbled together a temp one - attached. Needs some new levers/ wing nuts but will do at moment.  John |

|

|

|

Post by Scrit on May 8, 2008 18:46:49 GMT

After checking out the price of a new guard and discovering it is 3 1/2 times what I paid for the PT, I have cobbled together a temp one - attached. Needs some new levers/ wing nuts but will do at moment. Well, you could always try to do a deal with a local sheet metalworker to fabricate a guard for you in sheet steel in return for some woodworking. As to the levers and wingnuts I'd forget them as spares like that simply aren't available. The machine almost certainly has Whitworth (BSW) threads for the larger stuff and BSF for the finer stuff. Any decent engineer's merchants should be able to supply such items ex-stock, albeit rarely plated. If you don't have anyone local there's always Tilgear at Cuffley in Hertfordshire. As to knobs, etc, try George Coates, or Cotel as they are now called in Burnley. They make an astounding range of handles, knobs and Bristol keys, etc. Best of all the make a lot of it in house and can often supply stuff with a small diameter centre bore for you to drill and tap to whatever thread you need. Scrit |

|

mono

New Member

Posts: 8

|

Post by mono on May 8, 2008 22:39:39 GMT

Thanks Skrit. i just meant as an adjustment for my DIY guard actually. Cooksley - sorry, Whitehead, worked a treat on 1/3 m3 of oak today (and tonight!). Oh, I do love these old machines...Can't go wrong I reckon.

John

|

|

sidi

New Member

Posts: 1

|

Post by sidi on Jun 1, 2008 23:32:44 GMT

Hi all,

I have just aquired a Whitehead PTJ Thicknesser Planer , (three phase) but my workshop does not have three phase fitted yet is it best to have three phase installed or just to fit a invertor to do the job? any help would be welcome thankyou.

Paul(sidi)

|

|

|

|

Post by jonnyd on Jun 2, 2008 18:18:26 GMT

Hi i had a quote to install 3 phase into a building i was considering renting and the cost was about £10K so that put the scuppers on that but i did get the job of converting it into holiday cottages so all was not lost. It would be worth finding out the cost before you go any further as the invertor may be the way cheaper option unless you plan to get a lot more 3 phase machines.

Jon

|

|