|

|

Post by engineerone on May 24, 2008 15:47:19 GMT

picked up a record promotional leaflet today.  they are promoting their table saws, and making great play of having a sliding beam along side the blade. so the question is what is the value, of the sliding beam in normal usage, and are the latest record saws worth their money???  paul  |

|

|

|

Post by woodworker on May 24, 2008 20:22:48 GMT

Sliding beams or tables as they are more commonly called these days are very useful for cutting waney edged planks, on the higher end of the price range sliding table machines you can cut sheets using the slider instead of huffing & pushing the sheet against the rip fence you put in the slider with outrigger table attached and just walk with the slider using one hand, it's so much easier and depending how well the machine is set up you can get very very accurate cuts.

Also with the slider running against the saw blade it makes changing blades much easier & quicker.

As to Records quality, I notice they are badging machines from other known manufacturers rather than from unknown firms from the far east.

|

|

|

|

Post by Scrit on May 25, 2008 8:08:50 GMT

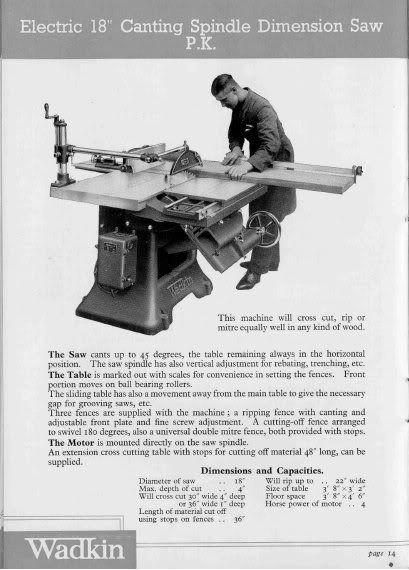

Woodworker has said it all The arrangement of a sliding left table piece appeared in the late 1920s/early 1930s when the "variety saw" (better known as a dimension saw these days) appeared. By placing the workpiece on a sliding portion of the table it was found that much more accurate crosscuts and mitre cuts could be achieved - essential in trades such as patternmaking or shop fitting. here's a photograph of a Wadkin PK saw which was first made in about 1929/1930:  As Woodworker says on the larger machines an entire sheet can be supported and that makes ripping an 8ft or even a 10ft sheet into strips (such as for the gable ends of wardrobes) much easier and more accurate:  But that does require a large sliding carraige strioke such as that shown on my Altendorf F45 above. I wouldn't say that blade changing is any easier/quicker, only different - you need to draw the carraige full back, engage the safety interlock, open the cover panel, move the crown guard out of the wayand climb in over the support arm to get at the saw blade - my ol;d Wadkin AGSP was quicker than the Alt I'd say Scrit |

|

|

|

Post by engineerone on May 25, 2008 10:28:40 GMT

thanks to both it clears up some more of the bullshit you find in the promotional literature these days. so scrit what about new record stuff  paul  |

|

|

|

Post by paulchapman on May 25, 2008 11:18:29 GMT

The new Record TS200C has had some very good write-ups. I've had a look at it at shows and it seems quite good. I'd seriously consider one for hobby use. Cheers  Paul |

|

|

|

Post by engineerone on May 25, 2008 12:41:13 GMT

certainly the spec looks ok, and at the present price it seems to compete with the dewalt 744 or its latest version, and the new bosch maching which has also had good results. the only problem i can see is there is little provision for under the machine dust collection. but i like the idea of the sliding beam, and the fact that it will cut up to 610 wide. good for most of us non pro's paul  |

|

|

|

Post by wizer on May 25, 2008 13:25:47 GMT

I didn't like the look of the TS200C when I saw it at Ally Pally. It seemed very poorly manufactured. All sharp edges and neither the fence nor sliding table where smooth. I think it would need a fair bit of fettling to make it run right.

|

|