|

|

Post by gazza on Aug 1, 2008 18:42:51 GMT

Hiya Paul  How are you today ? ;D As Scrit has said Oven cleaners will eventually affect the brazing, too harsh. and doesnt really do a good job.  The CMT stuff is great, for stubborn waxy resins on say canadian pine a soak for an hour or so works well. As for your quandry with the burn marks,  A process of elimination,  Clean the blade, ;D Check it is sharp,  Cut the Oak a little quicker, at a guess you are probably cutting it slowly( slower than you would cut pine) because its hardwood. If you are not using the workpiece clamp, try sliding the wood away from the blade as it has finished the cut , but before the blade stops. HTH, Gazza. |

|

|

|

Post by Keith on Aug 1, 2008 19:11:03 GMT

Burning will be most prominent at the bottom because that is where the teeth have most contact with the timber (or MDF ;D)

|

|

|

|

Post by tusses on Aug 1, 2008 20:13:07 GMT

For your benefit, Paul, the advised hand-blade separation on table saws, spindle moulders, etc is 400MM, not 100mm Scrit  oh dear ! I guess my 30 -40 is no good then, when I am 'being careful' is the 400mm type figure advised because it is known that idiots will operate machinery, so it is needed to keep them safe ? |

|

|

|

Post by jake on Aug 1, 2008 20:48:59 GMT

For your benefit, Paul, the advised hand-blade separation on table saws, spindle moulders, etc is 400MM, not 100mm Scrit  oh dear ! I guess my 30 -40 is no good then, when I am 'being careful' is the 400mm type figure advised because it is known that idiots will operate machinery, so it is needed to keep them safe ? It is more because whether idiot or not, the unexpected happens. 30 to 40 mm is very close - very much in idiot territory - no offence meant. I'm probably an idiot more often than I should be by the 400mm standard but I'd never stick my fingers that close. |

|

|

|

Post by tusses on Aug 1, 2008 21:22:24 GMT

I guess it depends on what I am cutting too. some woods / sheets cut smooth and I am happy to get a little closer - some chatter away and I reach for a push stick. If I am going to get close, I always double take my hand and foot position in prep and focus hard on what I am doing. I know what you mean about the unexpected, and I try to position mysellf so if something slips or kicks my hands move away from the blade. - no puching force towards the blade. Maybe I will come a cropper one day for not listening. My trouble is I have Norm ingrained , he will push his hands past the blade each side and he has all his fingers ! I have his vids/dvd's on all the time I am in the shop - sort of company. funny thing is ... there is no more important rule ... I wear my safety glasses before I do anything with tools, even a hammer and chisel but last night I was painting some garage doors without them on, and I got splashed in the eye  I guess I'll wear them for finishing as well now ! |

|

|

|

Post by big-all on Aug 1, 2008 22:40:08 GMT

Burning will be most prominent at the bottom because that is where the teeth have most contact with the timber (or MDF ;D) yep exactly the point i was making keith assuming your talking 4" wood after 3mm the top off the wood no longer get rubbed by the teeth edge where as at the bottom perhaps 50 to 100mm of rubbing takes place so your teeth rub between 3 and 100mm so obviously the bottom burns most now if your teeth are offset at an angle they dont have a side to rub  |

|

|

|

Post by Scrit on Aug 2, 2008 11:57:01 GMT

is the 400mm type figure advised because it is known that idiots will operate machinery, so it is needed to keep them safe ? Nothing at all to do with idiots who operate anything, Paul. As Jake says things happen. That's why the recommendation with chop saws is always to cut a short piece out of a long piece and to discard anything shorter than about 250mm - because below that you can't even clamp the piece down safely let alone hold it. I know it's a tempation to try to get the maximum out of a piece, but with power saws you do need to budget extra wastage to allow safe working (something which causes no end of arguments between the guys installing stuff and those supplying it, BTW) My trouble is I have Norm ingrained , he will push his hands past the blade each side and he has all his fingers ! I have his vids/dvd's on all the time I am in the shop - sort of company From what I've seen Norm is a very poor on safety, "wear eye protection then don't give a damn about your fingers". I've seen one-eyed woodworkers, but one handed sawyers are a rare commodity........ Norm has indeed got all of his fingers, but I'll bet you never see a kickback or any other "malfunction" on his videos. In the real world they do happen (and now we'll have the usual responses from that stream of "experts" who've never had one - to them I say saw up a couple of tonnes of timber a week for 3 or 4 years before posting, thank you) Scrit |

|

|

|

Post by tusses on Aug 2, 2008 12:14:34 GMT

I guess this is where outside world experience comes in to play !

It would be a big mistake to learn from !

Its hard to appreciate just how dangerous something might/can be until you have experience, 1st or 2nd hand of what can happen.

I have never been able to accept someone saying to me 'dont do that' without knowing why ! if you know what I mean.

In this day and age where you cant do anything without being told its dangerous or whatever, its hard to tell what actually IS not a good idea, or what IS just keeping the pen pushers in a job making up rules and regulations !

|

|

|

|

Post by Scrit on Aug 2, 2008 12:46:24 GMT

In this day and age where you cant do anything without being told its dangerous or whatever, its hard to tell what actually IS not a good idea, or what IS just keeping the pen pushers in a job making up rules and regulations ! Keeping myself free from injury is part of keeping myself able to earn a living, so from that perspective "safe practice" becomes an essential. I've found that Americans have a much more laissez faire attitude towards safety, but it doesn't take a genius to work out that if you have a cutting tool capable of ripping through hard iroko it will make light work of fingers, especially if unguarded (and from an engineers perspective our guards are very poor indeed). The whole reason we have mandatory safety standards is because of the tens of thousands of people who've been killed, maimed or injured in industrial accidents since the start of the Industrial Revolution. Remember, once you've amputated a finger or a hand they might be able to repair it, but it will never, ever be as good again, whilst heads can take a little longer to heal  My own experience from dealing with the HSE over many years is that legislation has very little to do with keeping "pen pushers" in a job. If people don't understand why a specific safety regulation is in place then they are probably unfit to carry out the task at hand - and if you are working with them they can be and often are a danger to themselves and others around them. Scrit |

|

|

|

Post by tusses on Aug 2, 2008 13:06:02 GMT

Take for example Gas and Electricity.

Regulations now say you cant do your own work. Yes its a grey area as to who is 'competant'

I have rewired many houses in the past, but I am not allowed to put a new ring in my own house now ! even if I know how to do it

I am not allowed to move my cooker from one wall the another. even if I know how to leak test

Take driving - one speed limit for all ! I have my advanced bike licience and am capable of being safe at a higher speed than some other riders - yet one rule serves all...

this is the kind of thing I am talking about - when you say the recommendation of 400mm, its applied across the board , hence my comment of keeping the idiots safe, and wondering if there is / should be leeway between idiots and those that have used equipment for years.

I hope what I am trying to say makes sense.

|

|

|

|

Post by Keith on Aug 2, 2008 15:47:45 GMT

Nope, I have to drive 10mph slower than most, despite having nearly 40 years accident free experience.

white van man ;D

We all have a bad day, work when we are tired or just get distracted for a second. I've had 2 "accidents" in the past few years. Good practice and good guarding saved me from a trip to A&E both times.

|

|

|

|

Post by tusses on Aug 2, 2008 17:19:22 GMT

It's good that you know your speed limits ! a lot of van drivers dont !

and agreed with the good bad days tired etc .

If I am tired I work accordingly.

|

|

|

|

Post by Dave S on Aug 2, 2008 20:52:33 GMT

oh dear ! I guess my 30 -40 is no good then, when I am 'being careful' is the 400mm type figure advised because it is known that idiots will operate machinery, so it is needed to keep them safe ? Do you not think 30-40mm is idiotic?  One of the problems as I see it is, the longer we get away with dangerous practice, the more complacent we get. When I worked as a motorcycle courier in London, I always used to thing the occasional 'near miss' was a good thing. It reminded me just how easily something really bad can happen and I would ride more safely as a result. Someone mentioned a somewhat relaxed attitude to safety the other side of the pond. On the SawStop site they reckon that there are around 60,000 injuries and over 3000 amputations a year from table saw related accidents in the USA.   |

|

|

|

Post by tusses on Aug 2, 2008 22:37:43 GMT

it's like when you mention the word 'DADO'  yes these blades can do a lot of flesh damage - but also there are a lot of people that use them safely. I am 99.9% ready to get a dado set. I just have to check that I can get the arbor nut to fit it with on my wadkin. I'll take some pics to show you what I mean about the 30 - 40 mm to me 400mm seems ridiculous ! and I dont realy want to come accross as trying to be 'big' and brave. I am just saying that if extra care is taken, then I cant see why you can't go further than the 'recommendations' would say you can. but I know I am in the minority on the 'hot topic' and it's been done and done to death so I wont push it too much |

|

|

|

Post by cuttingsolutions on Aug 3, 2008 13:15:09 GMT

it's like when you mention the word 'DADO'  I am 99.9% ready to get a dado set. I just have to check that I can get the arbor nut to fit it with on my wadkin. Dado set eh! The current rules insist that multple head/blade tools are pinned to stop them spinning freely...... How do they achieve that with Dado sets? who is selling these things? |

|

|

|

Post by tusses on Aug 3, 2008 13:21:12 GMT

|

|

|

|

Post by Scrit on Aug 5, 2008 11:05:17 GMT

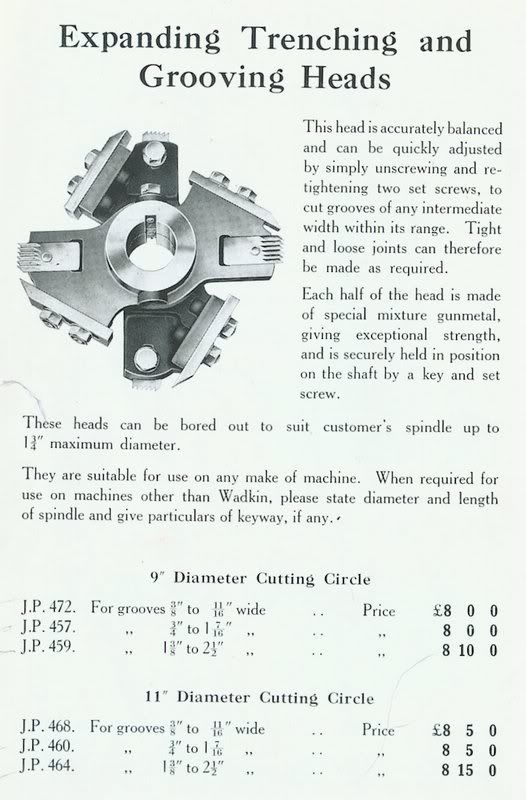

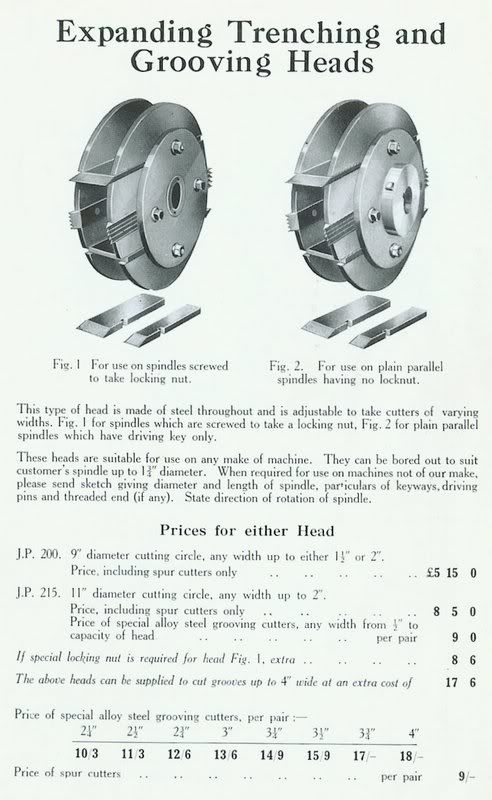

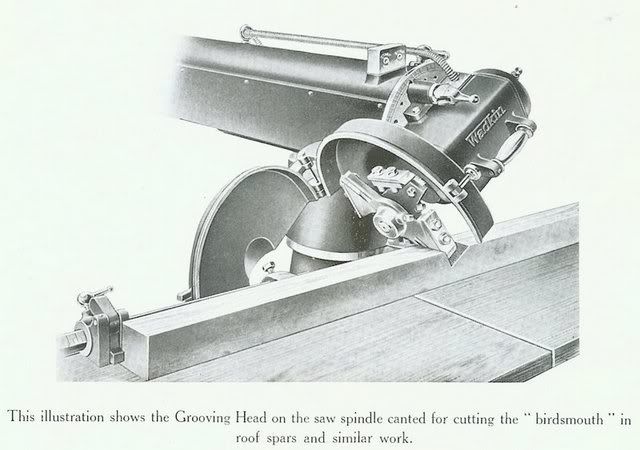

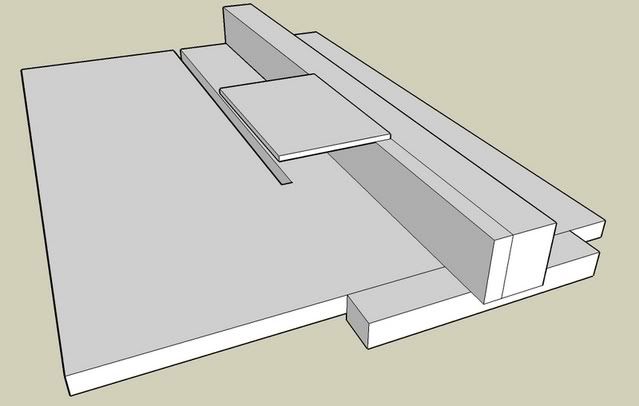

I have rewired many houses in the past, but I am not allowed to put a new ring in my own house now ! even if I know how to do it Not true. You can install your own but you are supposed to have your work inspected and signed off by a certified electrician. That isn't quite the same as not being able to do your own work. This legislation was put in place to avoid the all too common "kitchen fitter" scenario of a spur off a spur off a spur off a spur......... then a fire. If you don't know what I mean ask a qualified electrician - or for that matter a fire officer. When I install a kitchen I might pull through my own cabling, etc. but all the inspection and connection is always done by a certified Part P electrician I am not allowed to move my cooker from one wall the another. even if I know how to leak test I believe that there is a requirement to check for pressure drop and inspect pipework as well as to check for full combustion, adequate ventilation, etc. when moving gas appliances and that this has been so for many years. I've met very few kitchen fitters who've got the necessary test equipment other than a very few who are CORGI certified. Are you saying that you've purchased the necessary test gear or are you still relying on the old soapy water test for leaks? By all means do the work, but get it checked by someone who really knows what they are doing. Take driving - one speed limit for all ! I have my advanced bike licience and am capable of being safe at a higher speed than some other riders - yet one rule serves all... Funny. I thought that having an IAM licence wasn't the same as being a trained performance driver...... and remember if you hit me at 50 mph you'll kill me, at 30 mph you'll injure me, etc, etc. this is the kind of thing I am talking about - when you say the recommendation of 400mm, its applied across the board , hence my comment of keeping the idiots safe, and wondering if there is / should be leeway between idiots and those that have used equipment for years. to me 400mm seems ridiculous ! and I dont realy want to come accross as trying to be 'big' and brave. I am just saying that if extra care is taken, then I cant see why you can't go further than the 'recommendations' would say you can. Well you've failed miserably there ;D It sounds as though you are one of the idiots who needs to be kept safe! It is patently obvious from what you write that you've not only never had any sort of formal wood machining training, but that you can't even be bothered to read the safety advice on circular saws given on the HSE web site let alone read a book! I can, however, assure you that there is no leeway when dealing with exposed cutters. Zero. Absolutely none. A few of the most common "idiot mistakes" amongst the untrained/inexperienced are: " I need to see exactly where I'm sawing to do the job accurately/properly, etc" (so I'll remove the guard) " I'm very good/careful/'experienced' or 'safety is all in the head'" (so the 400mm rule doesn't apply to me) " I may not be a trained wood machinist but only idiots have accidents on table saws/spindle moulders/bandsaws, etc" " The average joiner is as sharp as a greased marble. I'm a computer programmer/marketing exec./property manager with a degree and therefore obviously more intelligent so I'm less likely to have a stupid accident" (despite a complete lack of training) " I've seen this done on (American) TV so it must be safe" or even " I've been doing it this way for years and I haven't had an accident to date" (so it ain't gonna happen :  A 12in circular saw spinning at 2,850 rpm has a perimeter surface speed of 8,949 feet per minute, i.e. about 150 ft/sec or a tad over 100 mph. Average human beings apparently have a visible stimulus reaction time of 180 to 200 milliseconds (e.g. if a light flashes) and an audible stimulus reaction time of 140 to 160 ms (e.g. the "bang" you hear when an off cut gets caught between fence and blade), so at 150 ft/sec a piece of timber will potentially move 140/1000th to 160/1000th of 150 ft (or roughly 21 to 24 feet) if it is accellerated to the same velocity as the periphery of the saw blade. That's why 100mm (4in or 1/3 ft) is too close, let alone 40mm (0.13ft). It's nothing to do with ability or experience, it's simply a matter of maths and physics. It just so happens than from a body of experience acquired over an 80 or so year period of accident analysis we now understand that a 400mm push stick is normally adequate to keep you out of trouble. And BTW 400mm it isn't legislation. It's just logic. From my experience those who are more likely to have accidents are those who do not understand how to use the machine, or those who know how it works but think they know better. "Being careful" and "common sense" when you don't understand how to use something won't get you out of trouble when something goes wrong. Fortunately for them most people never get it that wrong..... As for complacency I'm with Dave yes these blades can do a lot of flesh damage - but also there are a lot of people that use them safely. No, there's a lot of people using them who haven't yet had an accident. That's not the same as safe. And dado heads can do a bloody sight more than just flesh damage (says the man whe lost part of the bone from one thumb in a pin router accident)! The few pictures I've seen of dado head accidents indicate that they tend to be "draw-in" accidents in which the hand is progressively pulled into the cutter and that they involve deep laceration, bone damage and amputation. I've rarely seen adequate overhead guarding on table saws used with dado sets - and that's not "safe" by any stretch of the imagination. I learned about dado sets on a cast iron variety (i.e. dimension) saw rather like this one:  Note that the guard is similar to what is called a SUVA guard these days but is in fact the same type of guard supplied with British rip saws from the late 1920s onwards and is independent of the riving knife. The table to the left of the blade (viewed from the operators side) slides back and forth on ball bearings and has a substantial back fence with a massive and ridgid (by modern standards) mitre fence, finally the entire left side of the table slides out to accommodate a trenching head or stacked saw dado set. These saws were originally unbraked. The type of "dado head" we generally used was the two part trenching head, like this:  where the two parts interlocked or locked together on a keyed arbor shaft, although an expanding head which was similar to the hand plough plane was also available:  Both of these designs were safer in some ways than the stacked saw set as they were locked together as a single tool, however neither of these designs is legal today because they are not of chip limitation design One of the things I was taught was that you should never cut a rebate of housing in timber which was anything other than knot-free and straight grained. I've yet to see or hear that advice from any of the dado set adherents, possibly because they don't know it? In any case housings or grooves are more easily and safely worked using either a router and jig or on the crosscut saw:  also partly because of the inherent dangers of cross working any long timber on a circular saw other than a proper (i.e. Altendorf-style) panel saw. Modern practice is to use either a spindle moulder and rebate block (the best way), router and jig or a crosscut saw and dado set to work rebates rather than the table saw. All of those techniques keep your hands further from the cutters and are much, much safer than using a table saw. One of the issues with stacked saw dado sets is that if hand-tool contact occurs the extent of the injury is invariably much worse than for contact with a chip-limiter spindle block or a thin saw blade. This is because the cutters are not of chip limiter design and the rakers tend to hook in any material they come in contact with (after all that's what they are designed to do). The modern split 2-part groovers sold by Scheppach and deWalt are of completely different design:  much more like a spindle moulder tool. As limiter designs these tools naturally tend to cut somewhat slower than a saw blade, but their quality of cut is far superior and their design does limit the amount of damage they do when a hand-tool contact occurs. They also permit the machine's brake to operate. Note that Scheppach also supply an appropriate guard set for use with these on table saws:  The reason why braking at power down is so important is that it is the one and only way to reduce the chances of a run down accident. These are accidents where the operator switches off the (unbraked) machine and leaves the cutter to spin. Some while later he or another operator walks up to the machine and unwittingly pushes a piece of material or even a hand into the still spinning, but almost silent, cutter block. Won't happen to you? Think again. This was in fact one of the most common accidents on woodworking machines in trade shops prior to the mandating of brakes. Dado heads can indeed spin for 5 to 10 minutes on an unbraked industrial saw bench after power down So. You are intending to use an unpinned dado set on an unbraked saw, probably without a guard. Well, that's just plain stupid. Period. There is no argument which works in favour of stupidity, regardless of what Norm or his accolytes may say. Lest you accuse me of being anti-dado head, I'm not. I've used a dado head on a dimension saw in the past, although I would not use one today, and I still regularly used a dado head on a radial arm saw. What I'm anti is the blind stupidity that some folk seem to display when it comes to basic safety and guarding. The stupidest thing of all is that basic safety guarding is so easy to achieve:  but I know I am in the minority on the 'hot topic' and it's been done and done to death Obviously not when you are still utterly clueless about what safe practice is! You are a putative professional woodworker, yet you seem unwilling to take any steps to understand what safe practice is and how to implement it. If you succeed this is something your insurers will one day demand of you, let alone employees, the HSE and just plain "common sense" Scrit |

|

|

|

Post by davyowen on Aug 5, 2008 11:30:00 GMT

Not true. You can install your own but you are supposed to have your work inspected and signed off by a certified electrician. That isn't quite the same as not being able to do your own work. This legislation was put in place to avoid the all too common "kitchen fitter" scenario of a spur off a spur off a spur off a spur......... then a fire. If you don't know what I mean ask a qualified electrician - or for that matter a fire officer. When I install a kitchen I might pull through my own cabling, etc. but all the inspection and connection is always done by a certified Part P electrician Not quite ;D A Part-P registered electrician is not allowed to sign off on work that he hasn't done himself. In your scenario, as long as he can see the cable runs you have made and the electrician does all the connections then that is fine, but you'll have a job finding a quality electrician who will sign off on work done entirely by a domestic housholder with no electrical qualifications because a poorly made connection can test ok one week and be smoking hot the next. On the other hand a domestic householder can do all the work himself but it must be inspected after first fix by a suitably qualified inspector from building control and inspected/tested after second fix. Funny. I thought that having an IAM licence wasn't the same as being a trained performance driver...... and remember if you hit me at 50 mph you'll kill me, at 30 mph you'll injure me, etc, etc. Yep, I am currently having advanced lessons with an advanced police driver and registered IAM instructor/observer and he's made it very clear that under no circumstances will we ever be driving above the speed limit and that the only people trained to do that are emergency service personnel. Being an 'advanced driver' does not mean you are capable of driving safely at high speeds. Same applies when you substitute advanced driver with experienced driver... Until you have undergone training in the various aspect of high speed driving on public roads you are not capable of doing it safely, regardless of what you think. |

|

|

|

Post by tusses on Aug 5, 2008 12:03:44 GMT

Funny. I thought that having an IAM licence wasn't the same as being a trained performance driver...... and remember if you hit me at 50 mph you'll kill me, at 30 mph you'll injure me, etc, etc. Yep, I am currently having advanced lessons with an advanced police driver and registered IAM instructor/observer and he's made it very clear that under no circumstances will we ever be driving above the speed limit and that the only people trained to do that are emergency service personnel. Being an 'advanced driver' does not mean you are capable of driving safely at high speeds. Same applies when you substitute advanced driver with experienced driver... Until you have undergone training in the various aspect of high speed driving on public roads you are not capable of doing it safely, regardless of what you think. That was as I understand it for cars. I trained on a bike. I was taught speed limit plus 10% plus 1mph as the speed to aim for. So in a 60 we would have 67 on the clock. one of the reasons was that clock are made to 'over read' Add a little extra for a 'safe' overtake, and take every opportunity to progress through the traffic . The advanced police rider that I took my test with also told me which cameras to slow down for, and you can give the front facing ones a finger because bikes have no front plate. He also said, if I managed to get caught speeding he would be no where in sight ! The main part of the test involved twisty single track roads at considerable speed, and was quite mentally and physically exhausting. this was two years ago, and things might have changed since then. |

|

|

|

Post by tusses on Aug 5, 2008 12:28:04 GMT

|

|

|

|

Post by davyowen on Aug 5, 2008 12:34:08 GMT

I was taught speed limit plus 10% plus 1mph as the speed to aim for. So in a 60 we would have 67 on the clock. one of the reasons was that clock are made to 'over read' Add a little extra for a 'safe' overtake, and take every opportunity to progress through the traffic. Well compensating for an inaccurate speedo, or additional speed when overtaking was not what I had in mind when you mentioned the speed limit. Driving at 60mph, in a 60 zone when your speedo says 67 is not the same as someone driving 67 in a 60 zone because they think they can handle it. And yes the main factor of advanced driving is making safe progress so what you said is obviously fine, and legal. |

|

|

|

Post by tusses on Aug 5, 2008 12:44:01 GMT

unless your clock is more accurate than 10%  even so , I think the Car guys had to stick to the limit indicated by their clock ! |

|

|

|

Post by Keith on Aug 5, 2008 12:48:48 GMT

tusses I assume the photo's are a wind up, because I hope you don't think they show good practice  |

|

|

|

Post by big-all on Aug 5, 2008 13:36:00 GMT

tusses if you think those photo's show good practice then I despare  blade must be fully gaurded when blade is rotating before work is introducedno gap exceeding 6mm when wood is being cut riving knife must be fitted and properly adjusted when table in use ect ect |

|

|

|

Post by tusses on Aug 5, 2008 13:49:38 GMT

no - not 'good practice' just the sort of thing I use my TS for. a lot of the jigs and things mean your fingers are closer than 400mm. I mean , like, you couldn't use the mitre gauge without getting you fingers within a couple of inches from the blade. and with a sliding sled, I cant fit my riving knife or crown guard . nor can I for my finger box joint jig etc etc. take finger joints for example. It is not ripping, so the riving knife is 'less' important. there is no way to use the crown guard . I know some will say I should use a router table etc etc, maybe one day I will. I am just being honest here and saying , this is what I do !. If I rip , I fit the knife and crown guard. (until I found the forums I didn't) some operations I may not. if I am 'nibbling' half laps using my mitre gauge sled, then my fingers might be 20mm from the blade as I hold the piece against the mitre fence. without stopping for every pass and clamping the work down, there is no other easy way ! and whilst only cutting half way through, the knife and gaurd cant be fitted. I do like the idea of the 'easy' gaurd scrit posted . Thanks scrit  |

|