|

|

Post by wizer on Aug 5, 2008 14:01:54 GMT

I can see where tusses is coming from. It's hard to see the yanks using a dado, without such a debate in their community, and not think it normal. If one was to go down the dado route on a saw like tusses', would a guard like this be the sort of thing Scrit is talking about?  Please don't shoot me down. I'm trying to learn also |

|

|

|

Post by tusses on Aug 5, 2008 14:30:08 GMT

dont worry about getting shot down Wizer. I try to say stuff I think a lot of others are thinking/doing but to worried about posting. I've been on forums long enough now not to get upset by them, but to glean the usefull info out from the rest. I wear my safety glasses all the time since the 'finger tearout' thread - so there's an improvement  (sometimes, I just used to squint  ) |

|

|

|

Post by Scrit on Aug 5, 2008 16:07:08 GMT

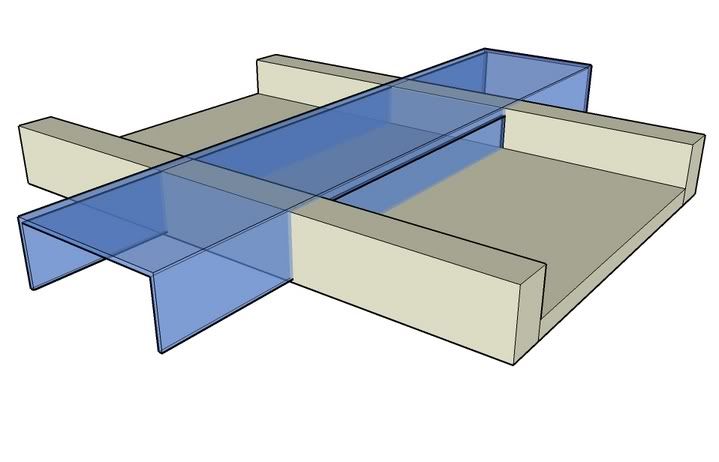

some examples of where I might get within a couple of inches of the cutting edge.  Please go and read HSE sheet no. 17 on safe use of overhand planers. It should rarely be necessary to use a push block like that on a planer with the possible sole exception of short pieces. The principle is that you always cover the cutter block as far as is possible and try never to run your hand over it. It also shows a lack of understanding of how to machine plane and where pressure should be put - put pressure on over the cutter block (where the workpiece is unsupported) and you'll end up hollowing the timber - so another reason to do it properly. Sleds can be fitted with top shields and a stop block at the back to prevent an unguarded blade exiting the rear of the device. This was discussed at length over at UKWS some time back where this type of mechanism was suggested by several members:  A design like this has also appeared in Fine WoodWorking in the past. A sliding table located to the left of the saw which allows the riving knife and crown guard to be retained is, however, much more convenient and safer (pity about the crappy rip fence):  A better bet might be to have the crosscut function taken "off-line" from the table saw and performed on a crosscut saw such as a radial arm saw or a chop (mitre) saw. Want to cut housings? Then a radial arm saw with a dado head or a router with a jig are both safer. And that's not just my opinion. So why couldn't this be performed with the crown guard in place, then? OK, so we finally have something which can't be done with a crown guard in place. Even then why couldn't better guarding be rigged up (such as a tunnel guard with the end shortened to accommodate the work piece). And why use fingers to hold the workpiece in place? That could be done with a £2 spring clamp and the fingers kept away from the blade. But then that may take three seconds longer a cut........ very important saving those 3 seconds in a non-commercial workshop, isn't it? This is the sort of thing I was taught never to do. At all (and that was in the early 1970s). The shoulders should be sawn by hand, on a bandsaw or using the table saw for crosscutting with an appropriate guard (see my previous response). In the absence of a tenoner or spindle moulder the cheeks are best done on a bandsaw or a radial arm saw with a dado head (there, used the "D" word, so what :  . The techniques shown were banned as a result of the 1974 Woodworking Machine Regs, and rightly so because they are dangerous (not to mention avoidable, unnecessary, etc) Only one example you show there is actually one where guarding couldn't or shouldn't have been used. Like I said before you really need to learn about how to machine wood and stop listening to the opinions of other similarly uneducated and therefore potentially dangerously ignorant amateurs on the net. Did you learn to ride a bike that way, or did someone teach you properly? I wonder. I'd suggest reading the appropriate leaflets at the HSE web site first. They're not holier than thou, they do show good, safe practice and you'll probably learn something to boot. I doubt you'll be able to fault them. Then if you are still interested take a look at something like F.E.Sherlock's book, "Machine Woodworking Technology for Hand Woodworkers" or alternatively Nigel S. Voisey's "Wood Machining" (he of VB lathe fame). Both a little out of date on the tooling side but nonetheless still worthwhile reads. Scrit |

|

|

|

Post by Scrit on Aug 5, 2008 16:11:51 GMT

If one was to go down the dado route on a saw like tusses', would a guard like this be the sort of thing Scrit is talking about?  Yes. Although a far better way would be to build a Shaw guard which both guards the blade and holds the work down:  Also remember that you'll need a run off table for all but the shortest of pieces Scrit |

|

|

|

Post by tusses on Aug 5, 2008 17:11:32 GMT

Thanks again scrit, for your reply. Like I said to Wiser, I try to post issues that inspire resulting posts. I have admitted that I am (as I guess many others are) 'Norm' trained. and I do find these threads educational ! the pictures that I posted were from a 'quick' search for push sticks . jigs etc. that most 'uneducated' woodworkers would find, if they were looking to do something 'properly !!! Scrit - your posts are in the minority. I guess you know this ? Even if they should be common knowledge and practice - they are NOT ! I do really appreciate your replies like this and I hope they will teach me and others to work more safely. It is your passion for safety the makes me question all I have learned so far ! so your posts are working ! - keep it up  Rich |

|

|

|

Post by Scrit on Aug 5, 2008 17:24:43 GMT

Scrit - your posts are in the minority. I guess you know this ? Even if they should be common knowledge and practice - they are NOT ! They may be in the minority on the Internet, however the real world is not the Internet. And untrained amateurs are not professional woodworkers. If you pick up any training manual published in Europe in the last 20 odd years you'll see pretty much what I say, regardless of language or country. If you ask any of the trained woodworkers on this site you'll find few who'll argue in favour of American safety and procedures over European. So, does that make me wrong? And if the Americans are so right why are they mandating riving knives on table saws very soon? Hell's teeth they'll be insisting on braked motors and decent rip fences next  And BTW, you still haven't answered the question about whether you are a self-taught motorbike rider or whether you were taught by a competent person. Scrit |

|

|

|

Post by wizer on Aug 5, 2008 18:15:21 GMT

Thanks for replying Scrit. I can see the benefit of holding the work down but then you loose dust extraction and visibility.

Am I to understand that with one of these guards plus a suitable outfeed table - the user is about as safe as he can be if he insists on using a Dado set blade?

I know you don't agree with their use but if these 'idiots' insist in using them, then maybe they need to be working as safely as possible.

|

|

|

|

Post by tusses on Aug 5, 2008 18:20:23 GMT

Scrit - your posts are in the minority. I guess you know this ? Even if they should be common knowledge and practice - they are NOT ! They may be in the minority on the Internet, however the real world is not the Internet. And untrained amateurs are not professional woodworkers. If you pick up any training manual published in Europe in the last 20 odd years you'll see pretty much what I say, regardless of language or country. If you ask any of the trained woodworkers on this site you'll find few who'll argue in favour of American safety and procedures over European. So, does that make me wrong? And if the Americans are so right why are they mandating riving knives on table saws very soon? Hell's teeth they'll be insisting on braked motors and decent rip fences next  And BTW, you still haven't answered the question about whether you are a self-taught motorbike rider or whether you were taught by a competent person. Scrit When I said you're in the minority - I didn't mean in any way you are wrong. I meant that if people like me search the internet for 'proper' woodworking practice, then the images I posted are what you would find. your views are not found on a 'quick' google search. which is why many of 'us' work the way we do ! The correct European 'current' working practices just dont come up in the search ! Many 'born again woodworkers' have just got the internet to learn by. No such luck of being 15 again and starting an apprenticeship ! Forums like these can either be a showcase for what people do in their sheds. or an educational channel for the wise and experienced to share with the rest ! please dont be offended - it is furthest from my intention ! As for my Motor Bike training - I am trained by advanced trainers and advanced police bike riders. Rich |

|

|

|

Post by engineerone on Aug 5, 2008 18:39:33 GMT

since you have a sled, why not introduce some holddowns to ensure your fingers are out of the way? on your tenoning and finger jigs you need to add a couple of g or quick clamps, and you avoid all the potential problems. one of the advantages of proper hold downs is that you ensure the work is accurately positioned and will not move under the forces of the saw. in addition it is much easier to cut accurately to length if you have proper hold downs. paul  |

|

|

|

Post by Scrit on Aug 5, 2008 22:25:20 GMT

Thanks for replying Scrit. I can see the benefit of holding the work down but then you loose dust extraction and visibility. I fail to see how you'll loose the dust extraction. If you are using a dado head to rebate then the dust extraction will need to be from the underside. Extraction from a crown guard is therefore somewhat moot as all the waste is generated on the underside of the cut......... As to visibility I have to ask what you think you are going to see. The cutting action occurs on the underside of the timber. there is no break through. The dado head should by rights already be partly embedded in a false fence plate attached to the rip fence and ideally the length should be set using some form of stop on the crosscut fence. So why do you need to see the cut? (In fact you can't see the cut......) Am I to understand that with one of these guards plus a suitable outfeed table - the user is about as safe as he can be if he insists on using a Dado set blade? No. If you are rebating short ends the safest methods are probably: 1. Spindle moulder with rebate block (or router table) 2. Hand router with fence 3. Dado head in radial arm saw or crosscut saw The latter is arguably much safer than a dado head in a table saw because the work is static (there can be safety issues with cross machining long pieces on a table saw in a crowded workshop). For long edge rebating the order is probably: 1. Spindle moulder with rebate block (or router table) 2. Hand router with fence with the dado head in table saw after that (long edge rebating in a radial arm saw is not that safe). For cross housings the table saw is a totally unsuitable machine and that process is best done by either: 1. Dado head in radial arm saw or crosscut saw 2. Hand router with jig But here's the rub. What materials are you actually working with? If you work predominantly with man-made boards such as MDF or chipboard/MFC then rebated/housed joints are actually inappropriate for the material as they create a potentially weak joint or upright panel. More appropriate jointing method would include biscuits, dowels or even Dominos - all quicker and stronger and less work, especially if you are using edge-banded materials. I know you don't agree with their use but if these 'idiots' insist in using them, then maybe they need to be working as safely as possible. But the safest way to use a dado head is in a radial arm saw............ not a table saw.  I meant that if people like me search the internet for 'proper' woodworking practice, then the images I posted are what you would find. And what I said was that the Internet is not the sole source of knowledge - in fact it is often very, very wrong simply because it is a random series of opinions which may or may not be supported by research or fact. Using it as a learning tool can be a bit like using the Daily Mail to determine the state of the nation. Unless you know the provinance of what you are looking at the Internet can be downright dangerous to your well being. As to finding proper training or technical manuals on the net I doubt that you'd find them for many other areas of endeavour, either (any geologists here ever seen the complete texts of Dudley Stamp's books on the net?). The people who publish training texts are trying to make a living so posting their work on the net won't bring them any return, which publishing a book will. Especially if that book is then taken up by the City & Guilds colleges as a standard text. I also happen to think that £20 for an instruction book on wood machining isn't bad value Similar views to mine can be found in many conventional instruction texts used by woodworkers doing City & Guilds, degrees, CITB courses, NVQs, etc. They are also quite near to what the HSE publish (on the net) as good practice. And they are free ;D Scrit |

|

|

|

Post by gazza on Aug 5, 2008 22:56:11 GMT

oh dear ! I guess my 30 -40 is no good then, when I am 'being careful' is the 400mm type figure advised because it is known that idiots will operate machinery, so it is needed to keep them safe ? There's stupid and then there's really stupid   Familarity breeds contempt ! Familarity breeds contempt !Tusses hopefully you will not someday be working with your saw and take your eye off for a split second and......................... Say no more Even years of experience does not outweigh safe working practises. Getting back to the original post, Paul i was cutting oak door frames today with my 718, original 60 tooth blade, rough cutting 7"x1.5" and then final cutting to size after planing and machining. No burning whatsoever. The blade isnt as sharp as it could be, but its clean. I tried cutting slowly, quickly, ect and it didnt make any difference. So try cleaning the blade and see if it helps. Cheers, Gazza. |

|

|

|

Post by engineerone on Aug 6, 2008 0:27:03 GMT

thanks for that gazza, there is obviously something wrong with my technique. i am beginning to believe that it is to do with leaving the blade to stop whilst still against the cut wood.  paul  |

|

|

|

Post by big-all on Aug 6, 2008 0:40:00 GMT

They may be in the minority on the Internet, however the real world is not the Internet. And untrained amateurs are not professional woodworkers. If you pick up any training manual published in Europe in the last 20 odd years you'll see pretty much what I say, regardless of language or country. If you ask any of the trained woodworkers on this site you'll find few who'll argue in favour of American safety and procedures over European. So, does that make me wrong? And if the Americans are so right why are they mandating riving knives on table saws very soon? Hell's teeth they'll be insisting on braked motors and decent rip fences next  And BTW, you still haven't answered the question about whether you are a self-taught motorbike rider or whether you were taught by a competent person. Scrit When I said you're in the minority - I didn't mean in any way you are wrong. I meant that if people like me search the internet for 'proper' woodworking practice, then the images I posted are what you would find. your views are not found on a 'quick' google search. which is why many of 'us' work the way we do ! The correct European 'current' working practices just dont come up in the search ! Many 'born again woodworkers' have just got the internet to learn by. No such luck of being 15 again and starting an apprenticeship ! Forums like these can either be a showcase for what people do in their sheds. or an educational channel for the wise and experienced to share with the rest ! please dont be offended - it is furthest from my intention ! As for my Motor Bike training - I am trained by advanced trainers and advanced police bike riders. Rich the internet is world wide as you know health and safety is uk wide if you put in good practices in to google you wont get good uk practices you will only get a selection of links with your chosen words in order of use in other words someones idea of good practice in america jamaca russia will score better than a search for shops and factories act 19xx that actualy apply ;D  |

|

|

|

Post by wizer on Aug 6, 2008 7:13:30 GMT

Thanks for the info Scrit. Whilst I understood your stance from post one. I was concerned with giving tusses the best advice possible for using a dado set on the tablesaw. I think it's clear that he's going to use one and by repeatedly telling him that he shouldn't will probably make him ignore your good safety advice even more. All the time a user can legally buy a dado set in the country then they will use one on their own opinion of safety. Using a SUVA style guard and an outfeed table will make him safer if he insists on using this method. Should he injure himself then he only has himself to blame. As did I blame myself when I injured my finger on the router table.

TBH My opinion is that the other methods can injure you if you loose concentration just as much as a dado head. Fair point the dado head will do more damage, but surely the emphasis should be on working safe with the tool to hand? Never loosing concentration and thinking about the method/cut you are using. Never let the work become so repetitive or seemingly simple so as to loose concentration. This is what leads to accidents.

|

|

|

|

Post by tusses on Aug 6, 2008 8:26:07 GMT

yes and no.

I will be getting the TS dado set, but I will also be looking to use it as safely as possible.

I really dont like using a router in hand held mode.

I wont ignore any thing - it all gets borne in mind.

I still find the 400mm thing odd, as that would mean you couldn't use a mitre gauge for example , because its closer than 400mm to the blade !

even so, I will be looking to use clamps more as suggested here.

|

|

|

|

Post by tusses on Aug 6, 2008 8:38:39 GMT

The other thing that occurred to me - what happens if you make small stuff ?

Dolls houses , or jewelery boxes etc etc

|

|

|

|

Post by engineerone on Aug 6, 2008 9:18:17 GMT

use a smaller saw?    ;D as for dadoes on the router, use or make a table. paul  |

|

|

|

Post by big-all on Aug 6, 2008 10:48:34 GMT

some operations I may not. if I am 'nibbling' half laps using my mitre gauge sled, then my fingers might be 20mm from the blade as I hold the piece against the mitre fence. without stopping for every pass and clamping the work down, there is no other easy way ! and whilst only cutting half way through, the knife and gaurd cant be fitted. I do like the idea of the 'easy' gaurd scrit posted . Thanks scrit  dont get mr wrong i would be lying if i said i had never taken the gaurds or knife off for cleaning and cut the odd tennon by mistake    the point being made is you must know what the bounderys are to allow safe working this include knowing health a safety so you know the minimum requirements |

|

|

|

Post by Dave S on Aug 6, 2008 12:36:52 GMT

I really dont like using a router in hand held mode. I'm curious as to why, as it is a very versatile tool which could enable you to take several of the more dangerous operations away from the tablesaw completely. Eg, Mailee has in recent months posted pictures of jigs for use with a hand-held router which can do dados (can't seem to find the thread at the moment) and tenons/half laps. Smaller pieces can equally be done on the router table. Dave |

|

|

|

Post by Scrit on Aug 6, 2008 12:39:16 GMT

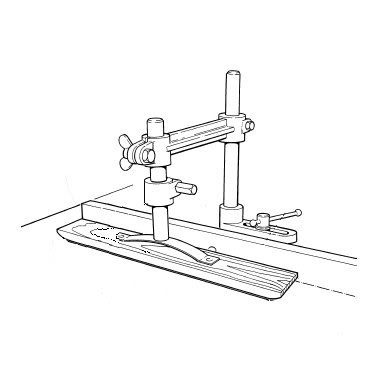

TBH My opinion is that the other methods can injure you if you loose concentration just as much as a dado head. Fair point the dado head will do more damage, but surely the emphasis should be on working safe with the tool to hand? Yes and no. The emphasis should indeed be on safe working, however, if you use a radial arm saw then the right hand is on the handle and the left hand should be holding the work to the left of the saw well out of the way of the blade and a properly set-up saw has a nose guard which tends to push hands, etc out of the way. Hand-held routers should be used with both hands on them whilst table mounted routers need to be treated with the same respect as spindle moulders, so Shaw guards, a power feeder or a sliding carraige are the order of the day. In fact for housings, etc the radial arm saw technique is even safer than the others simply because the work piece is static with no liklihood that it will tip or be deflected (as can be the case if machining a long piece in a small, crowded workshop) I'd agree that loss of concentration is a major factor and for that reason mobile phones are a pet hate of mine in the work environment. I still find the 400mm thing odd, as that would mean you couldn't use a mitre gauge for example , because its closer than 400mm to the blade ! The 400mm thing is a general guideline and is very valid, especially if you are pushing work into a blade or cutter. I've seen work get picked up and pulled sideways by a darned sight more than 20mm on mitre crosscuts and in those incidents you'd risk injury if your hands were so close. It's part of the reasoning behind joiners shops invariably using radial arm, cross cut or chop saws to do their cross cutting (the other being the time saved by not having to continuously swap blades on the table saw). The thing to remember is that if the workpiece is too short to hold you need to start thinking in terms of a jig or fixture to hold it, not your fingers. That maybe means coming up with a different approach to make the piece or using a bit of ingenuity - but that's what woodworking is about. It's about what you can do rather than what you can buy to do the job. In fact turners seem to think that way automatically, or so it seems. Maybe because they have no choice. For example, they seem happy to glue on an extension piece to hold work in the chuck and knock or saw it off after all the lathe work is done, much in the same way that in engineering lugs are often left on (or even welded onto) pieces so that they can be securely held whilst the main machining is done and when that is finished a secondary jig is used to hold the piece whilst the lugs are machined off. Agaimn from experience I can tell you that's how you onion skin multiple small components out of a large sheet on a woodworking CNC router. The safest way to get a small piece is always to cut it off a bigger one - not try to handle a too small piece - and if that means making 3 or 4 cuts or extra wastage or jigging it then that's just life. One of the common mistakes made by DIYers is to try to break-down and dimension only the exact quantity of materials they need for a given task. A tradesman will often allow a wastage factor of anything from 15% to 35% to cover defects in timber, miscuts, etc on stuff like small mitred mouldings. That way there's enough spare stock to avaialble to cover all eventualities. The other thing that occurred to me - what happens if you make small stuff ? Dolls houses , or jewelery boxes etc etc As Paul says, use a smaller saw. The machine should be to an appropriate scale for the work. Your AGS with a 10in blade will probably smash the 3 and 4mm thick stock used in some miniature work simply because the blades are large and the thin materials would not be adequately supported. For that sort of stuff hand tools are often a more appropriate approach, although some firms like Proxxon do make miniature tools specifically for the purpose. They bring with them a different set of problems in terms of how to hold work safely (so note the clamps):  (the copper pipe is 15mm in diameter)  (this saw is just 240x180x80mm and weighs 1.8kg - blade is 50mm in diameter)   (80 x 40mm thicknesser)  Finally, as big-all says, we all take off the on guard the table saw from time to time. But it's often the last resort because there is no other way to do things (the prime example I can think of being sawing off the tops of boxes). In a trained joiner's shop it's not something you'll see happening too often because it isn't safe and very often it simply isn't necessary. In general if you need to remove the guard you're doing something wrong somewhere........ so remember that fingers are easily damaged and hard to repair Scrit |

|

|

|

Post by tusses on Aug 6, 2008 13:42:33 GMT

I really dont like using a router in hand held mode. I'm curious as to why, as it is a very versatile tool which could enable you to take several of the more dangerous operations away from the tablesaw completely. Eg, Mailee has in recent months posted pictures of jigs for use with a hand-held router which can do dados (can't seem to find the thread at the moment) and tenons/half laps. Smaller pieces can equally be done on the router table. Dave when I made the garage doors, I spent an hour with my freud router making the tenons - at the end of that time my fingers were all spongy and tingly from the vibration. My dad has white finger from his time working with tools that vibrate. Its not a nice thing to have , and I dont intend to get it ! It was after this that I finaly decided to invest in a dado set. Apart from that - routers are very noisy and messy, and clumsy. I know you can hook up dust extraction, but I find that clumsy on hand held tools. Mine is quite heavy too which is quite strenuous when making a lot of large cuts. I have a little bosh 1/4 " one too, which is a lot lighter and I use that for smaller cuts. My TS is a literally pleasure to use and I enjoy its quietness and smoothness. I really do enjoy using my TS a lot ! My Delta 8" band saw is nice to use for similar reasons. very quiet. I will be making myself a router table setup. I had one before but I just dismantled it to make room for some cast iron  It was fine to use, but still noisy when cutting. |

|

|

|

Post by tusses on Aug 6, 2008 14:26:44 GMT

I made these crosses on the AGS with a crosscut blade in. They are about 6" across and about 1/4" thick. I halflapped them using my mitre guage sled - the half one not the full table sled. I do find I can make very delicate cuts with the ags. it is quiet smooth and taking a 64th or less off a small piece like this is no problem and it does 'feel' very safe to do. I didn't have to take the knife and gaurd off to do the 'nibbling' but the blade is only an 1/8" or so out of the table anyway. Its almost more like machining than woodworking. the wood sits on the sled which cant move sideways because its in the slot and I hold it down against the back edge. my fingers are close, but never heading towards the blade, always past it to the left side which is where i stand to do this too. This is the sort of thing I was meaning when my fingers get close. I take my time, and give it my full concentration.   |

|

|

|

Post by mrgrimsdale on Aug 6, 2008 20:04:12 GMT

I really dont like using a router in hand held mode. I'm curious as to why, as it is a very versatile tool which could enable you to take several of the more dangerous operations away from the tablesaw completely. Eg, Mailee has in recent months posted pictures of jigs for use with a hand-held router which can do dados (can't seem to find the thread at the moment) and tenons/half laps. Smaller pieces can equally be done on the router table. Dave I gave up using the horrid, noisy, dusty router entirely, as soon as I got the hang of the spindle moulder and realised just how limited the router is - except for one or two useful little jobs it can do, but I won't be replacing it when it finally goes. Mind you the bu99er won't go cos I never use it! I've got an antique B&D planer which never breaks down, for similar reasons. cheers Jacob |

|

|

|

Post by cuttingsolutions on Aug 6, 2008 21:15:03 GMT

I question again the usage of Dado sets. The EN847 regs state: Tools which belong to a tool set, or are part of a stacked tool, which do not in themselves meet the design requirements already described, should be designed in such a way as to prevent the parts being used individually, eg by using pins www.hse.gov.uk/pubns/wis37.pdfThe important bit is using pins. You CANNOT use a Dado set with pins. I will speak with someone who works closely with HSE to check the situation. |

|

|

|

Post by Scrit on Aug 7, 2008 15:20:57 GMT

when I made the garage doors, I spent an hour with my freud router making the tenons - at the end of that time my fingers were all spongy and tingly from the vibration. My dad has white finger from his time working with tools that vibrate. Its not a nice thing to have , and I dont intend to get it ! It was after this that I finaly decided to invest in a dado set. So you didn't think about inverting the router in a router table and passing the timber over it? Apart from that - routers are very noisy..... My TS is a literally pleasure to use and I enjoy its quietness and smoothness. Which is why we have ear defenders, which you should also be wearing when you use your saw. Rip certain timbers and plywoods and you'll need them, and if you ever graduate to a planer you might think that routers are quiet. As to your technique for cutting lalf laps - it's dangerous. Firstly you are attempting to hold very short pieces near to the blade with your fingers. That's a no-no. Secondly you are passing the work over the blade then presumably pulling it back over again. Another no-no because if you move the workpiece even slightly whilst doing this you might well experience a kickback, despite only making a shallow cut. If it does happen at best the timber will be snatched out of your fingers, there will be a loud bang and the piece will be ejected somewhere (and ruined). At worst you'll get bruised or cut fingers (I've seen those many times) but the very worst will be a hand to blade contact. You need another technique which is less risky IMHO. One problem that will occur is if you use a tecfhnique like this on 3mm deep cuts you'll probably not see any problem in going to 6mm, 10mm even 25mm cuts in due cours. And the deeper you cut the more hazardous your method of work becomes. And while I'm on the subject did you know that a straight-through rip fence like the one you have is another unsafe item? You really need to add a short rip fence plate (as shown in the HSE leaflet) if you intend to use a the fence for ripping solid stock or as a cut-off length stop. For a good article on that subject don't take my word, read the words of member Sgain Dubh (Richard Jones) from 1999. In the article you'll see a picture of Richard using two European-style push sticks simultaneously with the short position rip fence, riving knife and crown guard in place. Richard teaches woodworking at higher level as well as having been a working cabinetmaker so I feel his views are germain to this discussion BTW why didn't your Google search find that one, I wonder? Scrit |

|