|

|

Post by Scrit on Aug 11, 2008 22:13:32 GMT

OK, I'll admit I've got a bit of a bee in my bonnet about safety. Personally I don't think that's too much of a problem, even if the Normites do. Anyway I've started to turn my copious notes on wood machinig into something approaching a proper manual for my own use. First up I thought I'd share my "golden rules" with you and invite comments or even brickbats at my choices. Here are the fifteen I came up with:

Rule 1: The most appropriate and safest machine and tooling should always be used for any job. The tooling should be run at the appropriate speed and appropriate feed rates used

Rule 2: All machining operations should be planned so that infeed and take-off areas are clear of obstructions and necessary feeding and safety equipment are in place before starting a cut

Rule 3: Always check that cutting tools are properly installed on the machine and that cutters are properly secured

Rule 4: Check that cutters rotate freely and that guards and moveable fences, etc are secured before commencing a cut

Rule 5: Always wear appropriate safety equipment when machining and dress appropriately

Rule 6: Before using any machine for the first time seek guidance on its appropriate use

Rule 7: Always check for defects in the material before making a cut

Rule 8: Hand fed work must always be fed against the direction of cutter rotation

Rule 9: Any workpiece must be of sufficient size that it can be held and/or guide during the entire infeed and take off operation

Rule 10: Adequate work supports must be used for every operation

Rule 11: Never use any machine beyond its designed capacity. Be wary of using any machine to perform an operation for which it was not designed

Rule 12: Control waste and keep the floor around any machine clear of waste

Rule 13: Avoid external distractions when machining. Turn off mobile phones and iPods, etc

Rule 14: Avoid using woodworking machinery when tired or stressed. Never use any woodworking machinery when under the influence of alchohol or drugs

Rule 15: Always try to extract wood dust at the point of production. Wear dust masks whenever dust extraction is compromised

I leave the floor open to you gents for feedback

Scrit

|

|

|

|

Post by promhandicam on Aug 11, 2008 23:01:03 GMT

A couple of observations:

The second part of Rule 11 seems to contradict Rule 1.

It would be useful, for me at least, for you or others to elaborate on Rule 1. For example you mention in a recent post using an RAS instead of a dado cutter in a table saw. I don't have an RAS, however I would have thought with the kit I have a router in the router table would be the best option for doing this. Perhaps some sort of league table with a list of machinery in descending order of preference for different common tasks.

Rule 16. Always use push sticks when machining small or narrow pieces of timber.

Steve

|

|

|

|

Post by engineerone on Aug 11, 2008 23:11:42 GMT

i think scrit rule 1 should be having designed the item work out the most efficient way of producing the parts, using the material and machinery you have available to you. subject to it being suitable for the jobs you intend to carry out. and rule 2 check that the machines and tools you intend to use are clean, sharp, and capable of carrying out the work they were designed to do. and i do not agree that rule 11 conflicts with part of your 1. paul  |

|

|

|

Post by Scrit on Aug 11, 2008 23:39:10 GMT

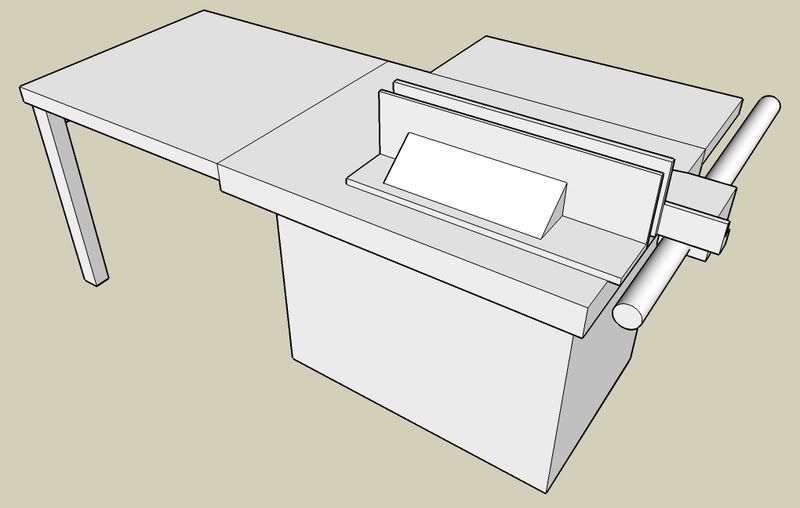

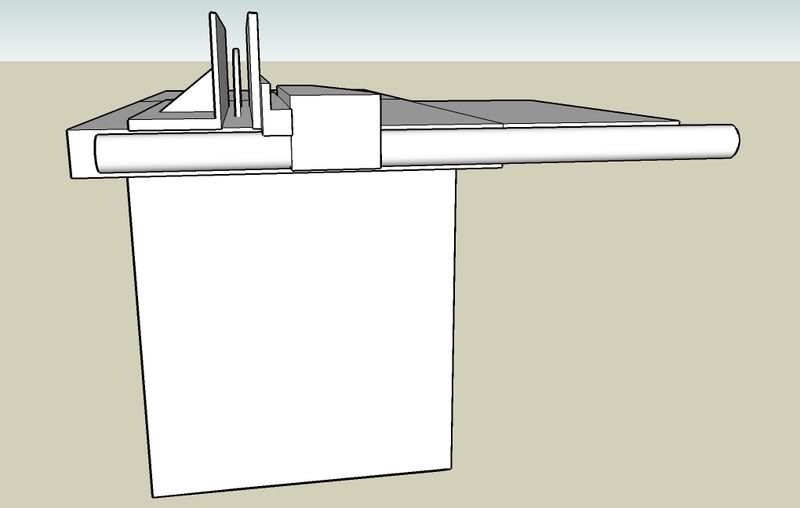

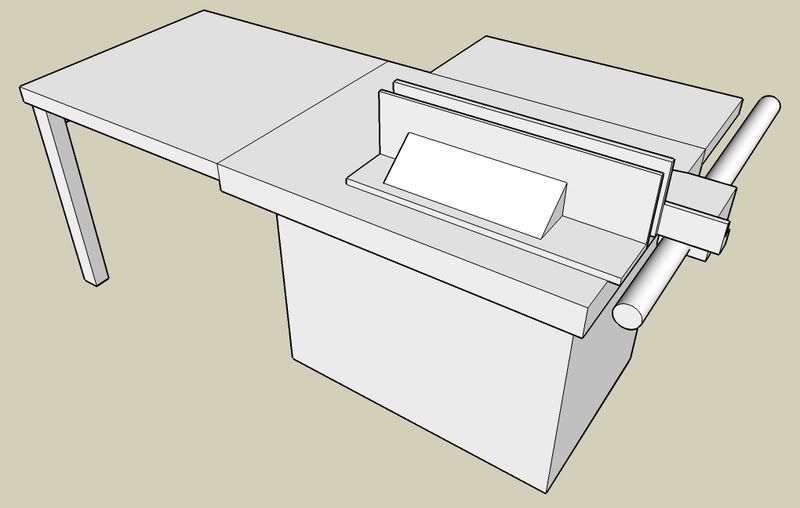

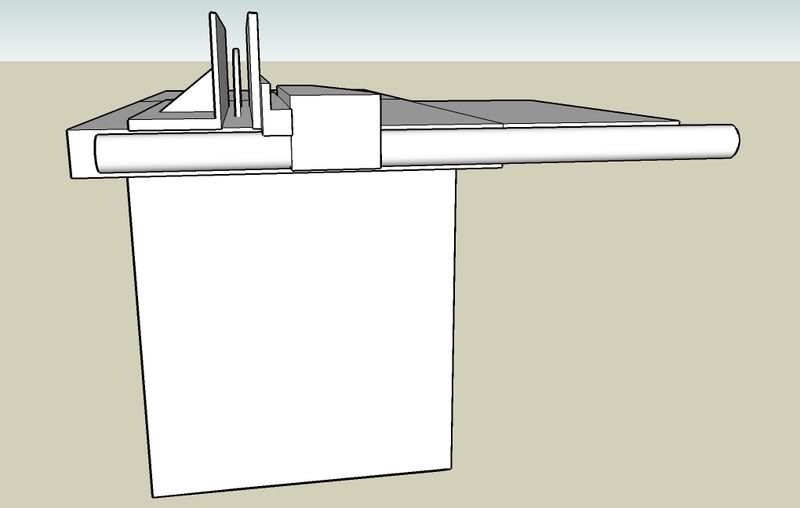

Thanks for the input thus far. The second part of Rule 11 seems to contradict Rule 1. OK. There are some instances where a machine is used for a purpose for which it is not expressly designed. For example "deeping" on a table saw requires the removal of the crown guard and on some machines the riving knife (although a crescent style one terminating just below the top of the should be fitted as replacement). You are therefore removing the guards and going beyond the design capacity of the machine, however, if a pair of deeping fences is used (hopefully these sketches will illustrate what I mean):   it is possible to carry out the operation relatively safely. ....you mention in a recent post using an RAS instead of a dado cutter in a table saw. I don't have an RAS, however I would have thought with the kit I have a router in the router table would be the best option for doing this. The HSE say something like " using the safest and most appropriate equipment for the task" (which is, I think, what Paul is saying). If you don't have a RAS and dado head or a spindle moulder then a router is an appropriate method of work. Given the choice between a spindle moulder, a RAS with dado head and a table saw with dado head to cut a rebate then thye would have to stay in that order. If, however, you wan't to cut cross housings (i.e. grooves, the original purpose of a dado head) then the order would be RAS, table saw. The router is probably about equal with the RAS, but the RAS is a higher volume device. Whilst a league table would potentially be useful I feel that there are far too many caveats to make it feasible. |

|

|

|

Post by Keith on Aug 12, 2008 8:07:25 GMT

Rule 14: Never use and woodworking machinery when under the influence of alchohol or drugs. Avoid using them when tired or stressed Small typo and some confusion; never take drugs when tired  ;D How about Rule 14: Avoid using woodworking machinery when tired or stressed and never use any woodworking machinery when under the influence of alchohol or drugs. Point taken. Good call! [Scrit] |

|

|

|

Post by tusses on Aug 12, 2008 9:48:52 GMT

I was going to mention the router in a table, but that's been covered.

maybe put something in there for 'up to date' practices, as the manual for the AGS includes the use of Dado heads , wobble blades , and AIIRC moulding heads too. all of which require the removal of the knife (which doesnt rise and fall ) and gaurd.

and also - I think for those operations like 'deeping' , maybe section of additional /auxiliary fences for safer working on such operations. That goes for a router table as well as a saw table, as you rarely see a photo of a router table with a cutter guard installed - yet it doesn't get the same attention as a TS.

|

|

|

|

Post by wizer on Aug 12, 2008 10:20:14 GMT

I think this is a good idea Scrit. I think that most people ignore the stuff from the HSE as the wording can make it seem irrelevant to what the users is specifically doing. It's not very 'human'.

The rule that I work on at the moment is "If it feels wrong, don't do it" I rehearse the cut/operation in my mind a few times to try to visualise what might go wrong.

I will print out a copy of your final list of Golden Rules and stick them above my bench.

|

|

|

|

Post by paulchapman on Aug 12, 2008 10:41:40 GMT

Excellent stuff, Scrit  That bee in your bonnet must have prevented numerous accidents already. Keep it coming. Cheers  Paul |

|

|

|

Post by jaco on Aug 12, 2008 11:10:37 GMT

Good guide!

;D ;D ;D ;D

Rule 5 - could one add:-

Hearing Protection

Face protection/goggles

Safety type shoes with toe caps

No slip-slops

and so on ........................

|

|

|

|

Post by Scrit on Aug 12, 2008 13:05:40 GMT

Thank you for your input, gents. I was going to mention the router in a table, but that's been covered Well they are, in effect, a sort of spindle moulder and so I think they should be treated as such. maybe put something in there for 'up to date' practices That is sort of taken as read, really. Or rather in a trade shop it should be. I'll see if I can incorporate something along those lines in the supporting text which is a bit more firm than what I've currently written the manual for the AGS includes the use of Dado heads , wobble blades , and AIIRC moulding heads too. all of which require the removal of the knife (which doesnt rise and fall ) and gaurd But since 1929 (the first Board of Trade WW machine regulations) there has been a requirement to guard an exposed cutting tool, it's just that in recent years the emphasis has been much stronger. As for other special applications I feel that they're really a bit far removed from a general set of rules which are after all meant to be bullet point hadlines, although my text does include a lot of specifics for different machines/set-ups Rule 5 - could one add:- Hearing Protection Face protection/goggles..... .....and so on ........................ Yes. There is an additional line or two (sometimes a paragraph or two) of text with each of the rules which goes into greater detail. I've included PPE (personal protective equipment) in that. What I think I'll do is add the additional lines in a separate thread when I'm satisfied with the "rules". Scrit |

|

|

|

Post by tusses on Aug 12, 2008 13:32:04 GMT

my point may well 'should' be taken as read, but to the beginner / amateur / weekend woodworker ... 'we' dont know unless we read it somwhere like this ! 'we' are not formally trained. which is what I guessed your safety rules are aimed at. As you say - anyone that has trained / worked in a commercial workshop 'should' know these things already. There are a lot of people like me that have 'learned' from norm - and when I bought my AGS I was delighted that the manual covered the dado heads and stuff  I know you have posted that you think I am a sh!t stirer, but I do learn (take in) from your posts, and I guess there are a lot in my position that are not 'thick skinned' as me and might not ask  I realy dont intend to upset you , or anyone else ! - just put accross my 'our' point of view that is now ingrained from these Yankee woodworking programs ! I have a few time life books on woodworking (yes - american) that show all the dangerous techniques I have 'learned' it is an eye opening experience to see/hear the HSE recommendations - and in this nanny state, its hard to adjust / believe, if you know what I mean. I do find your little sketches of easy and 'obvious' fences very interesting, and I 'will' be making some. its sort of a 'DOH!!!' moment, as they are so easy ! but , like I said - until you see it for the 1st time, it might not be that obvious. anyway ... rambling over ... back on topic Thanks again Rich |

|

|

|

Post by Scrit on Aug 12, 2008 14:30:46 GMT

When I was involved in production woodworking (i.e. small scale manufacturing) I found it necessary to write out a set of rules like those above and have it on the wall by the panel saw - even for the 'cogniscenti'. It started as 8 or 9 points and just grew as I discovered other things - sometimes the hard way. As to learning from "Knock-it-out-nailgun-Norm", it's a bit like learning pie making from Sweeney Todd - good end results, but getting there can be a bit dodgy!  Fair play to the man, Norm Abraham has done a lot to popularise woodworking, but in his own semi-autobiographical works "Measure Twice, Cut Once" he admits to never having received any formal training. He writes, " People often ask me where I went to school to learn carpentry. I absorbed all I know from watching my dad in his basement or by observing him and others on a job then trying the techniques myself. Or by just experimenting". Unfortunately his old man wasn't workshop trained either from what he writes. But more to the point Norm does tend to flout even the (often much) lower safety standards advised by the OHSA (American HSE). That's why I don't really trust him. He's a prime example of the blind leading the blind, although I'll grant you that he is a good showman ;D. As to this sort of place being the only place to learn, I'm not so sure. I've already pointed you to the HSE web site which has loads of good stuff on it (granted you've got to ignore some of the intros), and there are plenty of good British books available on the basics of joinery and cabinetmaking, especially those aimed at people studying the City & Guilds and CITB courses. Authors who spring to mind are Brian Porter and Reg Rose, Peter Brett, Les Goring, Ernest Joyce and Eric Stephenson. Take a look at Stobart-Davies (probably the best woodworking bookshop in the UK) and you'll see their books. I admit they're not such 'fun' reading as those nice American coffee table books which are stuffed with colour photos, but they do contain a lot more concise and proven technique. Maybe we need to post a bibliography over here. There are a lot of people like me that have 'learned' from norm - and when I bought my AGS I was delighted that the manual covered the dado heads and stuff  But didn't you stop to wonder whether in the 50 odd years since your machine was built safety had improved? It has on motorbikes and cars (I'm thinking helmets, halogen headlights, seatbelts, side impact bars, ABS brakes, radial tyres, etc), so wouldn't it be logical to assume that ther had been improvements in woodworking machinery safety as well? As to your comment about the HSE and the 'nanny state', I'm a mite tired of hearing that hackneyed epithet being rolled out every time someone does something dangerous or stupid as a justification for their actions. I really doubt you could point to anything in the HSE Woodworking pamphlets which is anything other than good practice. I can't say for non-woodworking related stuff. I do find your little sketches of easy and 'obvious' fences very interesting, and I 'will' be making some. In that case I'll post the minimum dimensions for them and some better illustrations in another post. Scrit |

|

|

|

Post by tusses on Aug 12, 2008 15:04:43 GMT

Quote But didn't you stop to wonder whether in the 50 odd years since your machine was built safety had improved? It has on motorbikes and cars (I'm thinking helmets, halogen headlights, seatbelts, side impact bars, ABS brakes, radial tyres, etc), so wouldn't it be logical to assume that ther had been improvements in woodworking machinery safety as well? As to your comment about the HSE and the 'nanny state', ....well maybe there is 'my' underlying problem. I really dont like the world and its ways as it is today ! I love to read about the old ways and how it 'used to be' ! I even make my own washing powder based on naptha soap and borax ! (imported from the states LOL ) I have around 20 cars. from the 50's to the 80's, most of them somewhere in the middle. I prefer the fact that you have to 'drive' these ! one even needs double de-clutching ! and yes , I am fond of the american V8's these 'mordern day improvements' hmmm ... not really my cup of tea. but none the less, I can see the merits of safe practise ! I'll maybe take your advice, and have a read of some British books  as long as they use feet and inches mind  as for the fence dimensions - no need really , just the picture is fine. Like I said, its just the idea that is 'obvious' ! Rich |

|

|

|

Post by wizer on Aug 12, 2008 15:52:39 GMT

Safety for the Modern Woodworker. IMHO you should put it all in a book Scrit. It would be as valuable as Joyce's works.

At very least it should be on a dedicated website.

|

|

simuk

Full Member

Posts: 111

|

Post by simuk on Aug 12, 2008 17:08:38 GMT

Hey Scrit,

Great idea, i will also stick it up on the wall as a reminder to me and as a pointer to anyone giving me a hand .

I always make sure the bottom half of my stable door is locked, before i start maching, so that no one can enter my workshop unexpectedly, like the postie , customers, ect.

Simon

|

|

ivan

Junior Member

Posts: 56

|

Post by ivan on Aug 16, 2008 12:20:36 GMT

Voisey's book on maching (A "Woodworker" book?) has been helpful, but is 20 odd years old and maybe out of print. You can also get a lot more machine for your money nowadays, and there was a lot it didn't include. Room for some up to date authorship?

Apart from schooldays I'm self taught, but the last 20 yrs of the day job was involved with on job training in the UK's most dangerous industry*so searching for books like Voisey's and trawling the HSE publications catalogue seemed quite reasonable to me!

* agriculture; highest death/accident rates

|

|

;D

;D

That bee in your bonnet must have prevented numerous accidents already. Keep it coming.

That bee in your bonnet must have prevented numerous accidents already. Keep it coming.

I realy dont intend to upset you , or anyone else ! - just put accross my 'our' point of view that is now ingrained from these Yankee woodworking programs !

I realy dont intend to upset you , or anyone else ! - just put accross my 'our' point of view that is now ingrained from these Yankee woodworking programs !