|

|

Post by mrgrimsdale on Dec 11, 2008 9:14:06 GMT

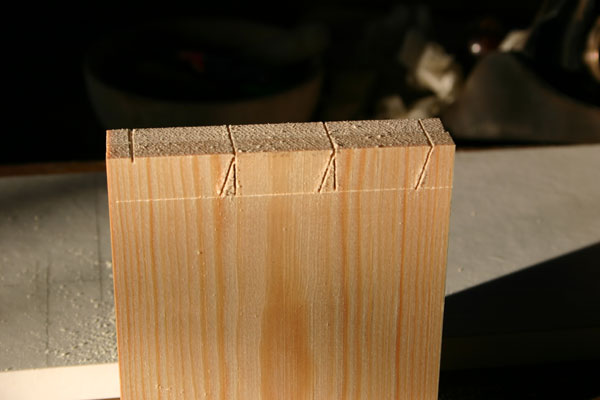

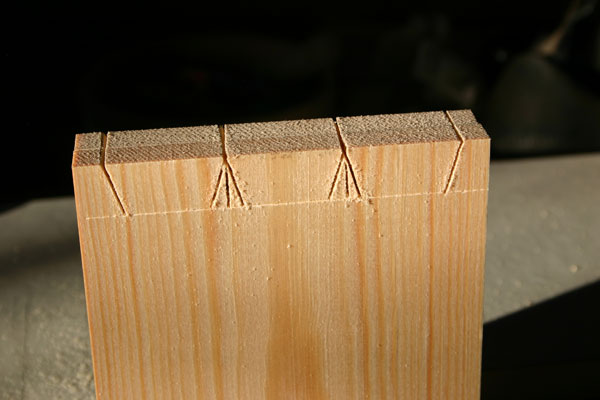

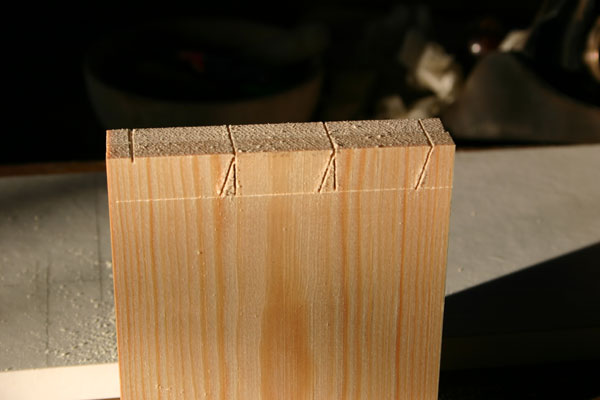

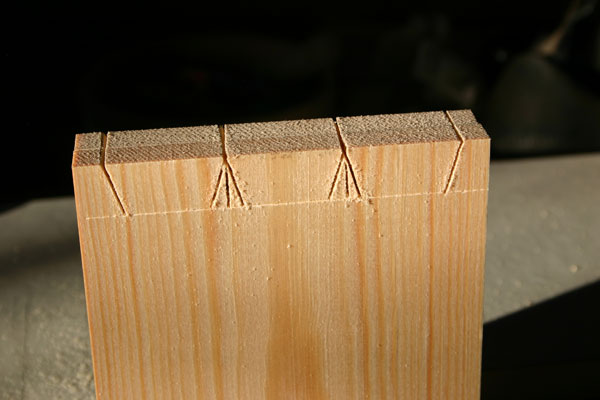

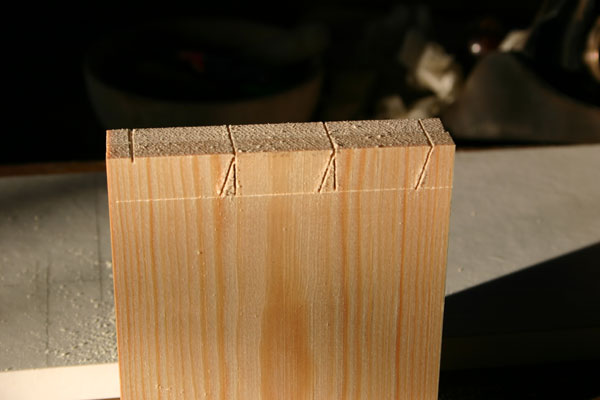

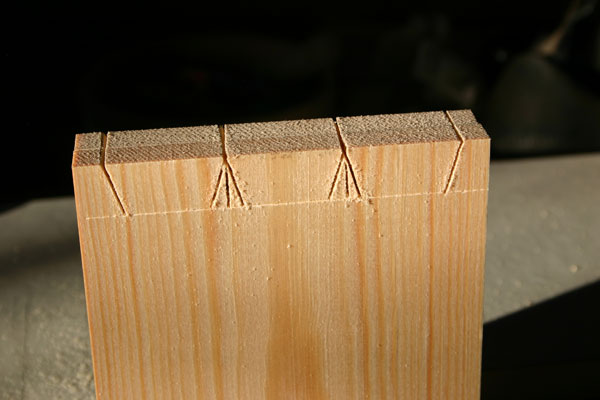

What you need is a dovetail saw, small chisel, square, pencil, marking gauge. Mark the shoulder lines and clamp your boards together in opposite pairs - face and edge marks absolutely essential for this. As many pairs together as you can cut with your saw. The first bit you can either measure and calculate, do by eye, or omit altogether (then you won't need the pencil ;D). 1 Mark in the outer pin lines with a square and a pencil, then divide the space between by three (or whatever number of tails you want) and mark in the inner lines (2 in this case making 4 in all).  Or you can go straight to step 2 and position saw by eye and with square: 2 Dovetail saw; nick the outer marks, cut the inner marks nearly down to the line, just roughly perpendicular, accuracy unimportant as long as they are square across the ends. They must be square as these first cuts are the guides for all the following ones:  3 Start saw cut in the top of each kerf and cut one set of tail sides at a time - it helps keep the angles roughly the same. Judge bevel by eye. Needs to have gradient somewhere between about 1:6 to 1:3. You don't have to obey the 1:6 or 1:8 rule if you don't want to. Go on - take a risk, be bold, be different ;D  4 Then the other side, start saw in kerf each time:  5 Chisel out the waste. Ideally with a chisel of same width as the pin hole, to get a neat edge. The central saw cut helps here as it gives the cut out waste space to move without jamming, and it will drop out easily.  That's it. Very fast. You could dozens of drawer sides in a day, if not hundreds. Marking from tails to pins: I'm experimenting with this and have to say that I find a marking knife very disadvantageous, for a very obvious reason; the cut it makes is on the wrong side of the line. The deeper the cut the harder it is to stop the saw slipping over into it. A 4H pencil is much better, and you can shape it to fit into a small pinhole |

|

|

|

Post by sainty on Dec 11, 2008 9:49:57 GMT

Interesting. I think I've seen Frank Klaus do something similar - not the three minute dovetails. Cant help but think that's only half the job Jacob. Looking forward to see the pins and finished joint.

rgds

Stu

|

|

|

|

Post by mrgrimsdale on Dec 11, 2008 9:54:25 GMT

..... Cant help but think that's only half the job Jacob. Looking forward to see the pins and finished joint. Me too ;D |

|

|

|

Post by paulchapman on Dec 11, 2008 10:43:23 GMT

..... Cant help but think that's only half the job Jacob. Looking forward to see the pins and finished joint. Me too ;D That's where it usually goes t*ts-up ;D |

|

|

|

Post by promhandicam on Dec 11, 2008 17:32:13 GMT

Good one Jacob. The only thing that I think I'd do differently is to cant the wood over in the vice so that I could saw straight down one side of each pin and then cant it over the other way to do the other sides - easier sawing a line perpendicular than at an angle. I'd probably also set up a sliding bevel so that the wood was always at the same angle in the vice.

Steve

|

|

|

|

Post by mrgrimsdale on Dec 11, 2008 19:58:56 GMT

Good one Jacob. The only thing that I think I'd do differently is to cant the wood over in the vice so that I could saw straight down one side of each pin and then cant it over the other way to do the other sides - easier sawing a line perpendicular than at an angle. I'd probably also set up a sliding bevel so that the wood was always at the same angle in the vice. Steve Nah too much trouble - take twice as long! Anyway you've got the first nicks and saw kerfs as saw guides. I'm not after a perfect poncy cabinet makers dovetail. I just want a practical joint - sort of 'optimum' rather than 'ultimate' product for the effort. A bit of quaint irregularity is OK as long as it's a tidy fit and a strong enough joint. |

|

|

|

Post by colincott on Dec 11, 2008 22:16:25 GMT

Hi Jacob That is kind of how I do mind e.g. I do not go by the 1:6 or 1:8 rule. I cut mine by eye and cut out the waste with a coping saw, to leave a little to chisel out and ofter a while you can cut them to look the same. It does not take much more time to make the sides the same of your dovetails.  |

|

|

|

Post by mrgrimsdale on Dec 12, 2008 7:45:21 GMT

Hi Colin

I wonder where the 1/6 1/8 rule came from as it doesn't make much sense - except if you do it flatter than 1/8 it's hardly worth the effort you can hardly see it. Maybe that's it - it's a minimum.

The idea of the straight cut and nick in my second photo is that it does 3 things - marks the square line across, provides a guide for the saw and avoids having to use a coping saw. If you are doing a lot then missing out the coping saw is a whole job saved.

Also, all the cuts are made in one operation without stopping, putting the saw down, taking the pieces out of the vice, or having a cup of tea!

|

|

|

|

Post by mrgrimsdale on Dec 12, 2008 15:48:56 GMT

Good enough for me. Less than absolutely perfect but perfectly OK for the job. I'm aiming at a fair hand made quality which can be done with some speed - how 90% of trad furniture was made.  |

|

|

|

Post by colincott on Dec 12, 2008 16:00:03 GMT

Jacob

I see what you mean as a different way to what I see as one of the easiest joints to do right, as long as you can cut a straight line with saw and chisel.

For me, using a coping saw means that all I am doing is paring the shoulder after but each to they own.

I think you are right that most furniture was made this way unless it was at the top end of the market, then I think things where done a little different but not by much.

|

|

|

|

Post by bugbear on Dec 12, 2008 17:50:21 GMT

That's it. Very fast. You could dozens of drawer sides in a day, if not hundreds. Marking from tails to pins: I'm experimenting with this and have to say that I find a marking knife very disadvantageous, for a very obvious reason; the cut it makes is on the wrong side of the line. The deeper the cut the harder it is to stop the saw slipping over into it. A 4H pencil is much better, and you can shape it to fit into a small pinhole I look forward to a photo of the pins being marked from those tails using a pencil. BugBear |

|

|

|

Post by mrgrimsdale on Dec 12, 2008 19:08:12 GMT

Too late I didn't take any. Will do next time. All you have to imagine is a pencil (not a fat carpenter's pencil)* sharpened with longish taper (could specify an angle for the pedants, lemme see, er, say 18 22 degrees ;D) which you can poke into the hole and work up to the edges, without necessarily reaching the furthest corners. Then you wiggle it about a bit. A lot more precise than yer 'pounce bag' proposed elsewhere  . * or 'carpenter's fat pencil' |

|

|

|

Post by derekcohen on Dec 15, 2008 13:49:33 GMT

Hi Jacob Nicely done on the tails! I find it easier to saw the tails with such tight/skinny ends than leave them wider. The first saw cut helps register the second saw cut. But BB is correct. This is the easy half of cutting dovetails. Almost not a challenge. The only aspect of importance is to get the cross cut square. In fact, gang cutting boards makes this easier still. The real trick is to mark and cut the pin board. Marking with a pencil .. now THAT would be a trick! I use a knife with a thin blade ...   This issue could be avoided if cutting pins first. Regards from Perth Derek |

|

|

|

Post by jake on Dec 15, 2008 14:14:45 GMT

I'm going to second-guess that Jacob's response to "ooh, pencil, impossible!", will be that you don't need a perfect mark all the way along the cuts, you just need sufficient markings to enable lines to be extended to mark the intersections (whether in the mind, or with a pencil and ruler). Join the dots (assuming you have sawn straight lines in the first place).

Bearing in mind Jacob is allowed some slack given his stated aims, that would seem perfectly reasonable.

|

|

|

|

Post by mrgrimsdale on Dec 15, 2008 15:40:22 GMT

Yes exactly. What's more - it's surprising how far you can poke a nicely tapered pencil into a small hole!

Agree about the tails being the easy bit. This a good reason for doing pins first perhaps - and that's the next thing I'm going to try on this voyage of personal woodwork development. Also even easier to poke the pencil.

Will use a knife for the shoulders though.

PS Re Derek's This is the easy half of cutting dovetails. Almost not a challenge.:

The challenge for me is to do them quickly and mindlessly with least kit. The point of my first vertical cut is that it's easier to get square than a sloping cut, guides the other two cuts and helps release the waste when you chisel it out without the help of a coping saw. So you can do all the cuts in one op, without even putting the saw down, without a coping saw, and without any marking out - once you feel confident and can accept the small variations.

|

|

jrm

New Member

Posts: 17

|

Post by jrm on Dec 15, 2008 22:37:41 GMT

One of the people who taught me, now retired, learned his trade as an apprentice. He told me he was expected to dovetail a chest of drawers in a day and would be in deep s**t if he didn't. An advocate of 'pins first', blaming that "b***dy Joyce book" for the proliferation of the tails first habit. He would saw down pins by eye, lapped or through, guessing the angle then tidy up anywhere if necessary before marking the tails. It's certainly easier to mark this way round where pins are fine.

Incidentally, I would describe his work as 'top end' as anyone else. Nevertheless, in his younger days he would have got a foot up his backside if anyone caught him playing about with a dovetail 'square'. The speed with which excellent results were obtained was just as important as the quality and I sometimes think all this pernicketiness erodes the value of the craft in a profound way.

Having said that, I have lapsed badly, marking carefully and cutting tails first. Maybe I'll have another go sometime.

John

|

|

|

|

Post by engineerone on Dec 15, 2008 23:00:56 GMT

nice work, jacob, and especially derek  interesting discussion too. however i do think there is something everybody is missing, if you are not cutting and making dovetails all day every day, then you are likely to be less comfortable with anything other than a measured way of doing it. if however, you have to make say 20-30 drawer sides, plus those of the cabinets, then by the time you have got to about the 12-15th you will feel sufficiently confident, and also probably pissed off enough to be much more freehand. however if you don't do it again for maybe a month or so, then rather like with some computer programmes, you will need to re learn the techniques. of course without practice it is difficult to judge the width and spacing of the individual parts because it is difficult to visualise. i too think cutting the pins first is the way to go in most instances, but it does not allow as much speed to be gained because it is difficult to gang cut them. of course you can also always repair some of the joints with veneers to make up any gaps  good learning curve though paul  |

|

|

|

Post by mrgrimsdale on Dec 15, 2008 23:02:25 GMT

Interesting. I can see how it would be possible to do a whole chest's worth in a day, (beyond me though  ). You have to be pernickety to start with, with most crafts IMHO and it's only when you can do it at all, that you can start working on speeding up. Pins first next time then! |

|

jrm

New Member

Posts: 17

|

Post by jrm on Dec 16, 2008 8:57:09 GMT

I agree, Engineerone. Gone are the days where every town would have a large and busy cabinetmakers and such work was repeated often. I think management attitudes have changed somewhat too! I can't say I lament the passing of the days where people learned such skills with a big stick behind them but it was such pressures that led inevitably to certain methods, not just getting p'd off. The old chap I referred to was a kind and caring teacher and all the more so because of his disapproval of the harsh world he had had to learn in. Thankfully, I can be as pernickety as anyone and hope to speed up a little. Eventually.

Nice knife Derek. Where did you find it?

|

|

|

|

Post by bugbear on Dec 16, 2008 13:34:59 GMT

|

|

|

|

Post by modernist on Dec 16, 2008 15:53:53 GMT

Got to be easier to mark the tails from the pins - knife or pencil.

I sometimes use a guide in the form of a piece of scrap with the angle marked on just standing on the bench. You can just sight up the saw to that to keep things even. ( I might even use MDF for that ;D)

cheers

Brian

|

|

woodchucker

New Member

Known to my family as 'His Bungleness'.

Known to my family as 'His Bungleness'.

Posts: 34

|

Post by woodchucker on Dec 25, 2008 11:16:25 GMT

One of the people who taught me, now retired, learned his trade as an apprentice. He told me he was expected to dovetail a chest of drawers in a day and would be in deep s**t if he didn't. An advocate of 'pins first', blaming that "b***dy Joyce book" for the proliferation of the tails first habit. He would saw down pins by eye, lapped or through, guessing the angle then tidy up anywhere if necessary before marking the tails. It's certainly easier to mark this way round where pins are fine. Incidentally, I would describe his work as 'top end' as anyone else. Nevertheless, in his younger days he would have got a foot up his backside if anyone caught him playing about with a dovetail 'square'. The speed with which excellent results were obtained was just as important as the quality and I sometimes think all this pernicketiness erodes the value of the craft in a profound way. Having said that, I have lapsed badly, marking carefully and cutting tails first. Maybe I'll have another go sometime. John Three cheers for your teechuur John, but there are times when tails first is a good idea, specially lap-dovetails on a 6 foot-wide bookcase. I found it easier anyway. Saved standing on a high stool and balancing the sides on my head, to mark the pins! (Think about it.) ;D ;D ;D I agree about the Joyce book too. I paid mure money than I could afford for mine, some years ago. There was little more in it, than there is in Charles H Hayward's lickkle books published by Evans's.  Jack |

|

woodchucker

New Member

Known to my family as 'His Bungleness'.

Known to my family as 'His Bungleness'.

Posts: 34

|

Post by woodchucker on Dec 25, 2008 11:53:43 GMT

Posted by Mr. G...

Good enough for me. Less than absolutely perfect but perfectly OK for the job. I'm aiming at a fair hand made quality which can be done with some speed - how 90% of trad furniture was made.

......................................................................................................

But not how most modern furniture is made! Not by a long stretch.

Mr. G your work is a delight to look at. If that's what you call "not 100%", well I look forward to seeing some what is!

One point; those fine tail sockets look strange in softwood, but then I always was one for 'Carpenter's dovetails' . ;D ;D

Jack

|

|

|

|

Post by mrgrimsdale on Dec 26, 2008 16:09:57 GMT

snip Mr. G your work is a delight to look at. If that's what you call "not 100%", well I look forward to seeing some what is! One point; those fine tail sockets look strange in softwood, but then I always was one for 'Carpenter's dovetails' . ;D ;D Jack Thanks for the compliment. It's just a matter of copying the old man's work - you can't go wrong! They shouldn't look that unfamiliar; there's tons of good quality ordinary traditional softwood furniture out there with drawer dove-tails much the same. They may be "fine" but they are also the easiest - both to set out and to cut. Praps fine is the wrong word - easier to think of as single kerf DTs Actually I'm not into 'fine' woodwork so-called. I don't even really like it! It's a devalued word IMHO. If you see " fine woodwork" it's like "purveyors of fine comestibles" - for fine substitute pretentious ;D ;D I really like very ordinary stuff - or primitive bodgery things done with axe and draw knife, which I keep meaning to have a go at |

|

|

|

Post by mrspanton on Dec 26, 2008 17:50:14 GMT

snip Mr. G your work is a delight to look at. If that's what you call "not 100%", well I look forward to seeing some what is! One point; those fine tail sockets look strange in softwood, but then I always was one for 'Carpenter's dovetails' . ;D ;D Jack Thanks for the compliment. It's just a matter of copying the old man's work - you can't go wrong! They shouldn't look that unfamiliar; there's tons of good quality ordinary traditional softwood furniture out there with drawer dove-tails much the same. They may be "fine" but they are also the easiest - both to set out and to cut. Praps fine is the wrong word - easier to think of as single kerf DTs Actually I'm not into 'fine' woodwork so-called. I don't even really like it! It's a devalued word IMHO. If you see " fine woodwork" it's like "purveyors of fine comestibles" - for fine substitute pretentious ;D ;D I really like very ordinary stuff - or primitive bodgery things done with axe and draw knife, which I keep meaning to have a go at who said stuff made with drawknifes and axe's were primitive? Its just one vital and essential aspect of our anglo saxon rural working class cultural identity-Skilled use of a few well designed "primitive"  tools combined with a profound understanding of the properties limitations and possibilities of natural materials, to create all manner of practical useful and attractive items. (ah thats why arty tradition hating pseudo intellectual middle class folk write it off as primitive-I forgot.....  ;D) its an activity that dependes on prcatical manual skill, not litetrary skill. LOL ;D No doubt you have noticed how many people that "get well into" fine woodworking scene, aspire to WRITE about so called "fine woodworking" as a carreer move? (that, and seek out the very latest aids, gadgets and fixes to side step the grubby issue of learning manual dexterity) |

|

.

.