|

|

Post by tusses on Jun 9, 2008 21:34:07 GMT

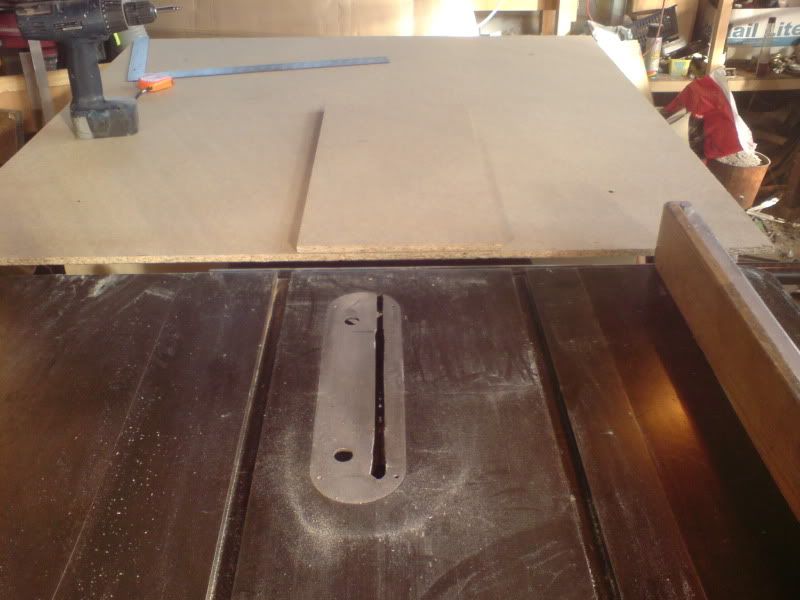

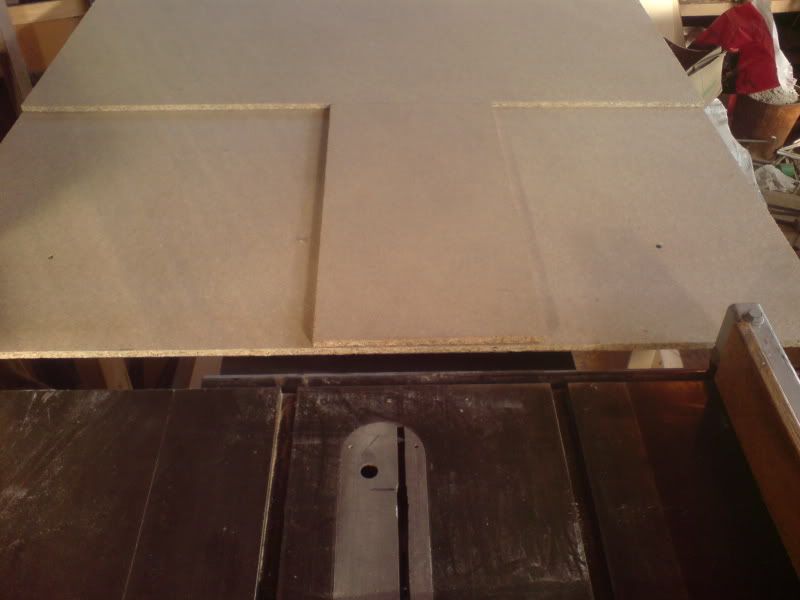

el cheapo No. 4 need I go on  anyway. I am upping my game and either tuning up or replacing my cheap / diy tools. my hand plane removed wood - but never cut straight. The blade wasn't square at the end - so I spent a bit of time flattening the back and squaring the bevel. on putting it back together - I noticed the whole lot is out of square :cry: have a look and tell me if its junk      It was cheap - so no matter if its junk - I just dont want to waste my time trying to grind everything square, if its a lost cause. any recomendation for an entry level plane ? Ta Rich |

|

|

|

Post by engineerone on Jun 9, 2008 22:16:31 GMT

to learn what you need to know, i suggest that you buy either a clifton or veritas or even lie nielson start with a 4 1/2 and you w ill learn what proper planes should be, then you can decide whether to bother ;D that looks too much of a problem paul  |

|

|

|

Post by tusses on Jun 9, 2008 22:24:17 GMT

I was thinking it looked a bit of bother ! hence the post ..... but ... I have seen the prices of the planes you mention  Yes .. I know you get what you pay for ! are the 'good' ones good out of the box ? or do they still need some work ? |

|

|

|

Post by modernist on Jun 9, 2008 22:35:26 GMT

Don't believe the note that says ready honed.

the back of the blade will always benefit from a final flatteneing/polishing but with the good stuff that is no big task. the body should b ready to go aftern adjusting the mouth etc.

Re your old one I would not bin it yet. The base/side only really matters for shooting and the mouth can be filed square and straight. the problem will probably be the blade quality where there is no point in buying a quality blade to put in such a body. Nevertheless I am sure it can be made useful if not collectible and, if the blade does not hold it's edge or is very rough on the back then sustitute a Stanley one.

Once you've tried a Lie Neilsen of Clifton I doubt you wil use it again though ;D

Cheers

Brian

|

|

|

|

Post by tusses on Jun 9, 2008 23:12:31 GMT

Thanks Brian

I think I might give it a go - even if only to learn a bit more about what makes them tick , so to speak

|

|

|

|

Post by engineerone on Jun 9, 2008 23:45:12 GMT

rich, yes i have seen the prices,  thing is i tend to think my time is worth a bit too. so rather than "waste " time fettling an old crock, and still not being sure it will do what you want.    i agree with brian you need a quick hone and clean up, but even from the box you will be surprised by what a difference you feel and see. so my view is spend 10-20 hours on a crock, or spend the same amount of money at 10 quid an hour, and get something that tells you what you are going to get.  try the veritas 41/2 at around 150 i think. very useable, and a decent general purpose plane paul  |

|

|

|

Post by engineerone on Jun 9, 2008 23:48:17 GMT

just quickly checked with the classic hand tools site and it seems to be about 185 in vat, so my idea was not too far out  paul  |

|

|

|

Post by tusses on Jun 10, 2008 0:25:09 GMT

I am definately with you on the time is money thing !

but in reverse, I find there is a gratification in working with a tool to get the best out of it.

The same goes for hand tools vss power tools - yes the power tools will save you time and money, but there is a different pleasure , I think of it as more of a craft/hobby (me time), using the hand tools.

|

|

|

|

Post by mrgrimsdale on Jun 10, 2008 5:38:42 GMT

I'd stick with it and get it working. Good training. Put a big camber on the blade for starters. A straight blade is difficult to useless. Flatten the bottom if necessary - just wet n dry on a bit of board will do, ignore the "engineering tendency". Take off high points: it wants to be flat to convex. Concave is problematic.

Then study how it cuts - try it out on the arris of a board , and then a board edge, before trying to flatten anything.

cheers

Jacob

|

|

|

|

Post by paulchapman on Jun 10, 2008 6:05:57 GMT

I flattened the sole of my old Record #4 on a coarse 8" diamond stone and oil - it worked well. You don't need to get the whole of the sole flat. Provided it's flat at the two end and either side of the mouth, hollows elsewhere won't matter. Go over the sole with a waterproof felt tip pen so you can see how you are progressing. Cheers  Paul |

|

|

|

Post by paulchapman on Jun 10, 2008 7:07:26 GMT

If you do decide to go to town on that cheapo plane, you might decide to fit a better blade and cap iron. It would certainly improve the performance, although the cost starts to go up and you wonder whether it might have been better to buy a more expensive plane in the first place. After-market blades are usually thicker (which is one of the reasons they work better). I use Clifton blades and their two-piece cap irons. Clifton blades are 3.1mm thick and this causes problems because the Y lever then won't reach the slot in the cap iron. There are several solutions to this. One is to silver solder a piece of metal to the end of the Y lever to lengthen it. This works on old Stanley and Record Y levers but not the newer ones which can melt  Rob Stoakley came up with a neat solution which was to drill the end of the Y lever  Then drill a piece of metal and glue it on with industrial super glue with a piece of metal rod going through the holes, like this  Here's the finished job  And here it is fitted to my Record #4  Another method is to fit a small piece of metal either side of the slot in the cap iron so as to, in effect, bring the slot closer to the Y lever. Of course, if you want to be really posh you can do what Pete Newton did and machine a new Y lever out of brass  But not many people would have Pete's skills at metalworking. Cheers  Paul |

|

|

|

Post by mrgrimsdale on Jun 10, 2008 7:25:19 GMT

Oooh I dunno, it's a slippery slope! Do you want to be a metal worker or a wood worker?

I'd still say stick with what you have got and make the best of it, or buy a better plane, but not necessarily the most expensive.

BTW tusses what did you mean: "my hand plane removed wood - but never cut straight".

My feeling is that it's the plane that removes wood, but it's the operator who makes it cut straight

cheers

Jacob

|

|

|

|

Post by paulchapman on Jun 10, 2008 7:41:53 GMT

Actually, I agree - buy a better plane. But just thought I would give some examples of what can be done if someone wants (or has time) to go down the fettling route. Cheers  Paul |

|

|

|

Post by tusses on Jun 10, 2008 8:19:40 GMT

I will no doubt buy a better plane soon, but I will work with this one a bit and learn all I can - and if I grind a little too much it wont matter !

I am surprised already at the amount of work and information there is on hand planes - as up to now I hadn't given them much thought (or use) at all.

As for cutting straight - the blade wouldnt come out of the hole (mouth? ) parallel to the sole., it always cut deeper one side than the other. I have only used it to chamfer the odd corner, or clean up a sawn edge for looks - but never for a joint , or working to a set dimension etc.

Thats why I started work on it last night !

|

|

|

|

Post by Alf on Jun 10, 2008 8:26:43 GMT

Standard advice for many a year has been that if you want to learn how to fettle a plane, start with an older Record or Stanley. At least that way you're starting with a better quality product in the first place, with the added bonus that the cast iron will have finished doing any moving it's likely to do. Putting effort into these sorts of plane is just casting so many pearls before swine; trust me, I know. I have a Hilka. But certainly you don't need to go down the new, expensive "outta the box" road to get results, and you'll learn a helluva a lot tuning one up for yourself. On the other hand, if you want to work wood rather than metal... Speaking as someone who's spent altogether too much time doing the latter when I should have been doing the former, I rather wish I'd skipped ahead to the Veritas/L-N stage and maybe I'd have a few completed projects and less of a tool mountain.  Cheers, Alf |

|

|

|

Post by promhandicam on Jun 10, 2008 8:39:04 GMT

Just wanted to add that the fact that the sides aren't square to the sole (picture 2) isn't a problem as long as you don't plan to use the plane on a shooting board. So don't go grinding loads away to try and make the sides square - it won't be worth it. Also in your last pic the frog isn't square to the mouth. Once you have flattened the sole spend a bit of time fiddling with the frog to get the iron protruding correctly.

HTH,

Steve

Steve

|

|

|

|

Post by mrgrimsdale on Jun 10, 2008 8:47:50 GMT

Just noticed frog not well seated in last photo. That's first little task and will straighten the blade in the mouth

|

|

|

|

Post by tusses on Jun 10, 2008 9:26:18 GMT

thanks for all your help ! I am getting somewhere now  the frog wouldnt sit square, so a few minutes with the angle grinder and now it will. working much better so far  I still have a lot to learn - like which way round does the blade go  I really know nothing It only seems to fit one way (bevel down) so thats how it is at the moment. I'll have to google around and read up thanks again  |

|

|

|

Post by engineerone on Jun 10, 2008 9:29:09 GMT

whilst you can learn lots about planes and plane making, plus some metal working skills  not sure how much you learn about woodworking.  as alf said. certainly apart from the sides and baseplate not being at 90degrees to each other, the major source of your problem is the frog not being square to the slot. but of course you need to see that the slot (mouth) is square to the front of the plane. then undo both smaller screws on the frog, one is clearly ahead of the other, and fettle the frog to be in line with the slot(mouth) this will certainly improve part of the process. personally though i would still try one of the better brands to see what you are missing. and actually, it is worth buying one of the block planes for around a ton. they are very useful, and give you the better understanding and show what can be done with a properly machined and assembled product. paul  |

|

|

|

Post by tusses on Jun 10, 2008 9:34:02 GMT

My block plane is from Wickes - it was about 3 quid LOL !!! I did get it sharp and working ok tho. You are right of coarse - I need some better tools

|

|

|

|

Post by paulchapman on Jun 10, 2008 9:47:41 GMT

I still have a lot to learn - like which way round does the blade go  I really know nothing It only seems to fit one way (bevel down) so thats how it is at the moment. Yes, it's bevel-down. Cheers  Paul |

|

|

|

Post by tusses on Jun 10, 2008 10:36:45 GMT

With a bit of blade sharpening .... some thin shavings - nice and see through end some end grain oak - couldnt do that before !    |

|

|

|

Post by Alf on Jun 10, 2008 10:37:13 GMT

Not sure how many of the links are still extant, but you might find this helpful. Probably a few dozen useful ones on here as well. Cheers, Alf |

|

|

|

Post by engineerone on Jun 10, 2008 11:38:37 GMT

well done, silk purse out of sow's ear comes to mind ;D paul  |

|

|

|

Post by Scrit on Jun 11, 2008 19:24:37 GMT

There's a hell of a lot of BS waffled about the need to spend loads of dosh on the best plane going....... Take a look in any site jopiner's kit and you'll see just two or three planes; a block plane, a smoother or jack and possibly a bull nose. they may well not be the best planes (often Records or Stanleys), but they do have their blades properly sharpened and honed and the breakers set correctly. The need for high price polanes is often over stated when the real need is for a plane which is sharp and well set first

Scrit

|

|