|

|

Post by andy king on Jun 17, 2008 16:16:27 GMT

snip trying to find where you last left off by round honing could have you faffing around before you find the right spot to raise a wire edge. OK, so on my 25 degree flat or hollow ground chisel, I lift it to 30 and start raising a wire edge. I'm removing minimal steel. You are saying that on a round bevel, if I can't get a wire edge, still held at 30 degrees, I should drop the handle, remove steel that doesn't need to be removed to accomodate the fact the chisel is bottoming out before actually raising the wire, and to do so, I have to rub the round face, with far more surface area than a secondary bevel, pick the handle back up and try again?  Pointless and time consuming. Nope. Rounding means you are addressing more steel to the stone whether the final cutting angle is 30, 40, 25 or whatever degree takes your fancy. A secondary beve is just that. It rubs. The primary bevel doesn't, therefore, even as it gets wider over its honing period, the secondary bevel will never have as much steel addressing the stone as a curve if you are to maintain that curve and retain the cutting angle you say you are. If you have to lift the tool higher to obtain a honing angle, which is what I think you are implying for those who don't 'round bevel' hone, then again, your technique is poor. Andy |

|

|

|

Post by andy king on Jun 17, 2008 16:29:44 GMT

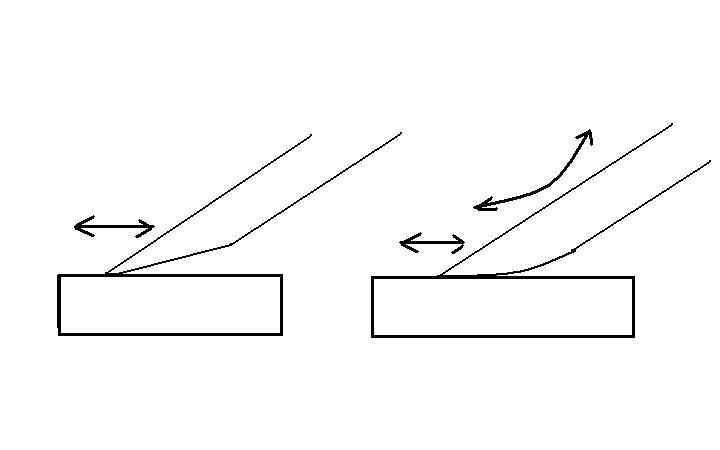

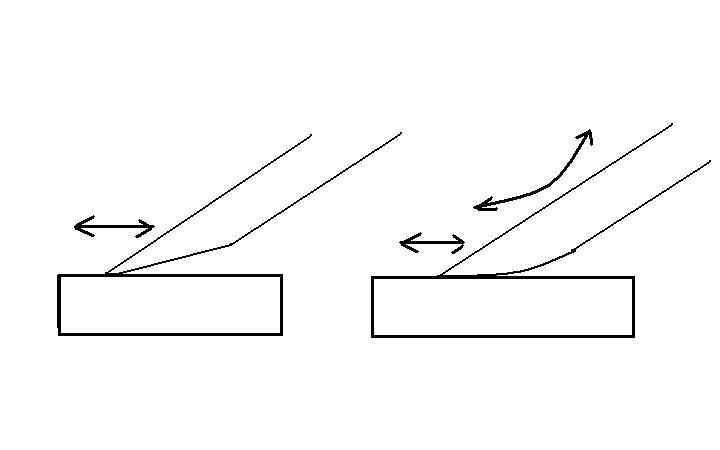

Here you go. Both still retaining the same honing angle. On the left, tradtional technique, secondary bevel, motion front to back, minimal metal contact, less effort. On the right, dipping while moving front to back, more metal contact, more effort, poor technique. (In my opinion)  |

|

|

|

Post by mrgrimsdale on Jun 17, 2008 17:03:22 GMT

Don't quite follow that. Don't think you've got it.

You've got it ;D. Have a go and you'll see what I mean.

NB with convex bevel sharpening you are backing off at the same time which means you never need to grind on a machine (until you have a damaged edge). IMHO many edges spoiled by grinding/overheating esp beginners.

cheers

Jacob

|

|

|

|

Post by andy king on Jun 17, 2008 17:28:07 GMT

Err, why should I want to move from a technique where I can remove minimal metal, keep my tools in good order and get razor edges with minimal effort for one where I have to sacrifice a perfectly good bevel, remove more metal and put more effort in?   Having a double bevel or single also means you never have to go to a grinder if you don't want to, the secondary one eventually becomes a primary, single honing angle, much the same as you bang on about, but without it being round, asuming you are daft enough to want to keep removing huge amounts of metal by hand on a stone, your way or this one. Luddites of the world unite!  |

|

|

|

Post by mrgrimsdale on Jun 17, 2008 17:46:00 GMT

No you obviously haven't got it! BTW it's the same amount of metal however you do it. cheers Jacob PS I only keep banging on about it because people keep asking, since I first banged on about it  |

|

|

|

Post by engineerone on Jun 17, 2008 17:50:01 GMT

i must just comment on the idea of wacking your mortice chisels all the time.  in my view it is dangerous to do such a thing on sections of 25mm or less square, since it seems to me you are likely to bruise the wood at the bottom, or go to deep by wacking. the actual cutting time was only 10 minutes per mortice, so i would rather have the control and freedom than wacking.  paul  |

|

|

|

Post by andy king on Jun 17, 2008 19:53:35 GMT

No you obviously haven't got it! BTW it's the same amount of metal however you do it. cheers Jacob PS I only keep banging on about it because people keep asking, since I first banged on about it  Nope, i've got it. You have said that you dip to create and maintain your round bevel, therefore, nature of the beast - more steel in contact through the movement that needs to be removed. It can be said that a secondary bevel hits the stone by the same amount but less time is needed as less steel needs to be removed to obtain a wire edge as you are removing only where necessary, at the edge. Explain to me how in the right hand diagram, your round bevel removes the same amount of steel if you dip it through the process compared to a simple honing action as the left indicates? Are you Paul Daniels? Am I missing your 'And that's magic' moment? |

|

|

|

Post by mrgrimsdale on Jun 17, 2008 20:33:33 GMT

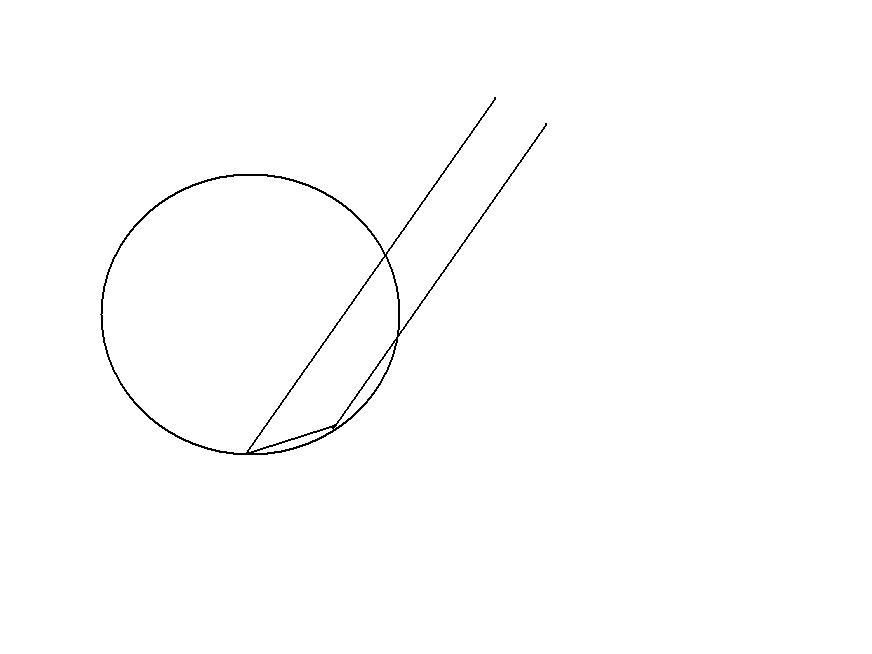

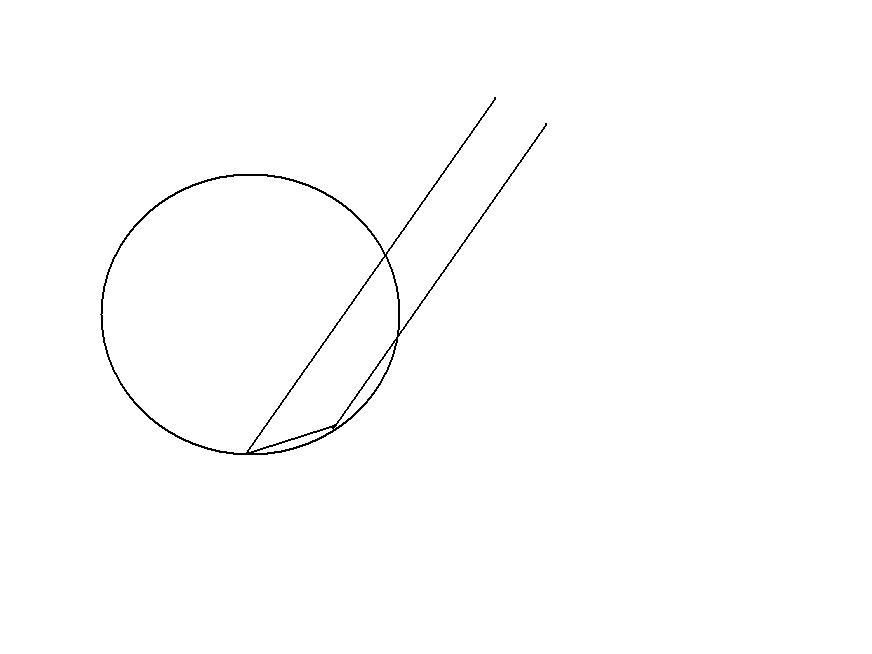

Nope you haven't got it ;D Consider the following sketch. 4 chisels identical except for having strangely different bevel shapes. Each needs 1mm removed to sharpen the edge, as shown by the dotted line. What you will find is that the area removed (or volume in 3D) is exactly the same for each, as long as each new bevel is identical to the old one. Or look at the last one, the area of the parallelograms A,B,C are identical, if they have the same base 1mm. You can prove it with geometry.  cheers Jacob PS convex bevel sharpening includes the ground bevel which you are leaving out of your left hand drawing which shows the honed bevel only |

|

|

|

Post by andy king on Jun 17, 2008 21:44:24 GMT

Ummm... how can a flat single bevel be equal to that of part of a circumference   It may be minimal, but still more surface area.  edit: Having looked at you diagrams and the way you've worded it, yes, of course removing the same amount from each of your sketches will be the same surface area as before but not identical to each other. The diagram above proves that, a curved surface will need more removed than a flat, and that is where your method will always require more work in my opinion. |

|

|

|

Post by dexteria on Jun 17, 2008 22:56:37 GMT

cheers Jacob Woss that then: Sketchup Mark 7.1 I presume? Very effective, almost like the real thing! Ho Ho ;D |

|

jmk89

New Member

Posts: 37

|

Post by jmk89 on Jun 18, 2008 4:12:22 GMT

Nope you haven't got it ;D Consider the following sketch. 4 chisels identical except for having strangely different bevel shapes. Each needs 1mm removed to sharpen the edge, as shown by the dotted line. What you will find is that the area removed (or volume in 3D) is exactly the same for each, as long as each new bevel is identical to the old one. Or look at the last one, the area of the parallelograms A,B,C are identical, if they have the same base 1mm. You can prove it with geometry.  cheers Jacob PS convex bevel sharpening includes the ground bevel which you are leaving out of your left hand drawing which shows the honed bevel only I think that I follow it, but your diagrams are not really to the point. The top diagram is a primary bevel only. The second is a hollow ground primary and I assume that you then are showing a honing bevel at the same angle - in which case there will be NO metal to remove in the hollow ground part, which is the point that the advocates of hollow grinding make. The third is your rounded bevel and the fourth is impossible - how do you take that section with any grinding or sharpening medium. Actually what you will do with either flat or round bevel is remove the metal on the peaks until you get to the smooth surface (flat or rounded) that you want - whether there will be more or less metal to remove will depend more on the pattern of the roughness of the start position than the shape you are trying to achieve. You also do not show the two relevant diagrams - honing a secondary bevel where you have a flat primary bevel - much less metal contact - and restoring a primary bevel - the top diagram is not it, because the area at the tip does not exist for this exercise and will be less the longer you persist with the flat secondary bevel. Having said that, a round bevel does tend to be more robust - it can be used on a firmer chisel if you want to make it strong enough to cut mortices, but frankly, I would just raise the primary bevel to 30 or 35 degrees and the secondary to 35 or 40 to get the same effect. I will admit that this is done with a WASP using a zirconium belt with a very rigid jig, as described here: www.piricdesign.com.au/articles/hints-tips/another-sharpening-device.html |

|

|

|

Post by mrgrimsdale on Jun 18, 2008 6:28:43 GMT

Right then ;D

Read the way I've worded it: not same surface area, but same area of diagram, or same volume of metal in 3D = same amount. The last diagram shows bevels with differing surface areas, different thicknesses, but all identical amount of metal to be removed. Basic geometry, no trick.

;D ;D

You might hone a little bevel, but eventually you have to regrind, so in the end it's the same amount of metal whatever the overall sequence - which covers your other comments.

cheers

Jacob

|

|

|

|

Post by andy king on Jun 18, 2008 8:52:47 GMT

Regrinding isn't an eventuality if you simply decide to keep a single bevel once the hollow is worn back, it's a matter of choice.

That is exactly the same scenario as your round bevel theory, hit an angle and maintain it and you don't need a regrind.

You still haven't answered though - your round bevel removes more metal than a single flat bevel, and therefore, more work to do so, even if its minimal. The geometry I have indicated proves it. Yours proves nothing, it's irrelevant to this discussion of whether a round bevel removes more metal than a flat one when achieving an identical honing angle.

|

|

|

|

Post by paulchapman on Jun 18, 2008 10:04:50 GMT

Good job we're not discussing something complicated, or we'd be here all year ;D Cheers  Paul |

|

|

|

Post by jaco on Jun 18, 2008 11:19:49 GMT

I will have to print this lot out, sit at the workbench and try and figure what is what ............. This looks like at least a 6 can exercise ....................   |

|

|

|

Post by mrgrimsdale on Jun 18, 2008 11:52:46 GMT

Wrong. Nil pointes. You'll have to work it out for yourself or we'll be here all day.  cheers Jacob PS The key is in that last sketch: each of those quadrilaterals has the same area. The shallower the angle the longer they are, but thinner. Works the same with any parallel sided figure including curved ones, if they have the same base (1mm in the sketch) and lie between the same parallels (face and back of chisel). |

|

|

|

Post by andy king on Jun 18, 2008 12:59:09 GMT

Well, your own description of round bevel sharpening states dipping the tool to keep the curve constant so you never have to regrind, so more surface area will be eroded than that of a flat bevel if the profile is to be maintained. End of the day Jacob, if your method floats your boat, so be it. I seem to have managed to freehand hone for the last 30 years without having any problems. Perhaps i'm lucky...  |

|

|

|

Post by mrgrimsdale on Jun 18, 2008 13:33:38 GMT

The crunch killer detail which I forgot to emphasise is that a flat bevel has the whole area of the bevel pressing down, but with a convex bevel there is only a tiny bit of metal in touch with the stone at any time. Together with the fact that you can press down harder (less care needed except for the first stab at 30deg) this accounts for convex bevel sharpening being so much quicker.

The other detail which I found by chance, is that you can go down a grade or 2 in grit sizes. I've got a fine stone which was virtually useless when used with a honing guide, or flat bevel freehand. Could use it to put a shine on small chisels but that was about all. But with a convex bevel having more "attack" it has become use-able and useful.

So not only faster but also finer.

cheers

Jacob

|

|

|

|

Post by derekcohen on Jun 18, 2008 14:24:08 GMT

Hi Jacob For reference, your illustration of a hollow grind is so inaccurate that any arguments made in regard to it would be terribly misleading. With the use of a Tormek, I grind to the edge of the bevel. This allows one to create a true microbevel, one that requires a few strokes on 1000 waterstone to remove the rough edges, and a couple of strokes each on 5000 and 8000 grits (I use Shaptons) to create a sharp edge. The Tormek further enables the hollow grind to be created at a desired angle - such that this may be freehand honed guided by the sides of the hollow without the need for a higher secondary bevel (I wrote earlier why I avoid higher secondary bevels). Lacking a picture of a chisel blade, here is a plane blade (a tapered Matherson) that was honed at 25 degrees with a microbevel:  The edge - and the bevel angle - can easily be maintained on a leather strop between fresh honings because the bevel is effectively flat. Now I do not know whether your rounded bevel is capable of such ease in honing. It looks to me to be so because you are not really concerned about maintaining a specific bevel angle. And that it works is again something that I do not doubt since I have seen the quality work you do. But where the rounded bevel starts to fail for me is in the area of "re-sharpening". With a hollow grind it is easy enough since one is using the established profile. The microbevel may grow slowly into a non-micro bevel, but it should withstand many (10? 20?) honings before the hollow is re-ground to create another microbevel. With the rounded bevel, unless one is removing some of the round back, the bevel angle must increase. The question is "how many times can you do this before the bevel angle is either unusable or ineffecient?" My expectation is that re-sharpening requires a regrinding of the rounded profile. Regards from Perth Derek |

|

|

|

Post by mrgrimsdale on Jun 18, 2008 16:07:46 GMT

Well no, this is the whole point: the bevel shape and edge angle never change. You take off a thin sliver of metal over the whole bevel, every time you hone and /or grind. Honing/grinding are kind of combined in a casual way - I can see that it wouldn't suit an engineer or metal worker, but it suits me as a woodworker!

cheers

Jacob

|

|

|

|

Post by engineerone on Jun 18, 2008 16:33:02 GMT

frankly jacob, on this subject i think you are talking hogs breath   what you are suggesting is simply NOt possible in simple terms. you are trying to justify a system that seems to work for you by using pseudo science like you accuse others of us in other areas. so stop trying to prove the unproveable. ot ain't gonna work  passing thought, my local makro is selling a couple of pieces from the meister range. so i bought a chrome vanadium chisel 26mm wide, for 2.99 plus vat,, will see what it comes out like  frankly i'm with derek and andy  paul  |

|

|

|

Post by mrgrimsdale on Jun 18, 2008 17:09:16 GMT

Righto Paul I'll stop it immediately  No it doesn't work at all. ;D ;D I now realise that the reason why my chisels and planes are sharp is due to the elves which come in during the night whilst I'm asleep - well it must be, what else could it be? cheers Jacob |

|

|

|

Post by engineerone on Jun 18, 2008 17:11:03 GMT

as usual you misread jacob, i said that whilst it might work for you, the science you are trying to promote in the way you are trying to promote it is worng paul  |

|

|

|

Post by Alf on Jun 18, 2008 17:31:28 GMT

Ack, stick some brass knobs on everything and all will be well. ;D

This and the "why does a plane work" are very valuable threads. They remind me why I must not allow myself to get theoretical on matters woodworking. I don't understand it and it doesn't make sense.

Cheers, Alf

|

|

|

|

Post by mrgrimsdale on Jun 18, 2008 17:45:45 GMT

as usual you misread jacob, i said that whilst it might work for you, the science you are trying to promote in the way you are trying to promote it is worng paul  What science? Nowt wrong with the geometry of that's what you mean. I do have moments of self doubt believe it or not. Just popped into the workshop to test it out again. Sharpened a rough old 1" firmer. Very quick, very sharp, so sharp I cut myself   cheers Jacob |

|

Pointless and time consuming.

Pointless and time consuming.