|

|

Post by paulchapman on Jun 18, 2008 17:54:05 GMT

so sharp I cut myself   Mustn't laugh ;D ;D ;D ;D ;D ;D ;D |

|

|

|

Post by jfc on Jun 18, 2008 18:24:36 GMT

Make of it what you will but i have three pig sticker that all have rounded bevels . I cant see someone who doesnt know how to sharpen a chisel having a pigsticker or sharpening it so much that it has a rounded bevel so it must be an old trade tool  |

|

|

|

Post by mrgrimsdale on Jun 18, 2008 18:30:40 GMT

Well you might not remember but it was the rounded bevel on mortice chisels which originally sent me round the bend over there

Question was - it it works for them, why not for everything else?

cheers

Jacob

Jason - I like the avatar - could do with sound effects big drum rolls and massed choirs ;D ;D

|

|

|

|

Post by jfc on Jun 18, 2008 20:19:08 GMT

Thankyou , it was a birthday pressie  |

|

|

|

Post by andy king on Jun 18, 2008 20:51:13 GMT

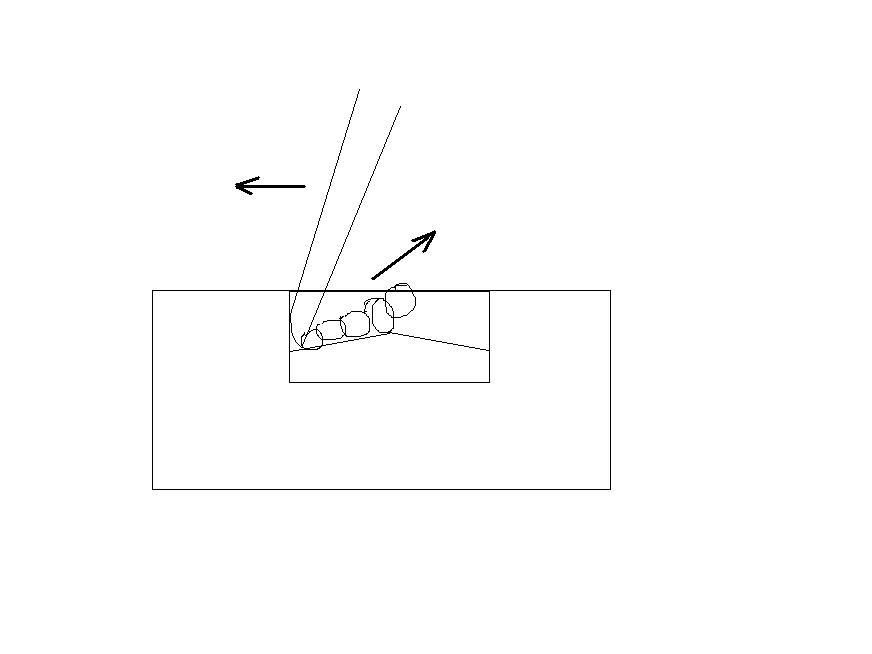

Make of it what you will but i have three pig sticker that all have rounded bevels . I cant see someone who doesnt know how to sharpen a chisel having a pigsticker or sharpening it so much that it has a rounded bevel so it must be an old trade tool  OK, at the risk of this starting all over again, mortice chisels are levering tools as well as cutting tools (even sash mortice ones, but lighter duty) To lever off a flat bevel isn't as easy as rolling the chisel around a curve when breaking and loosening chips.Hopefully this diagram although a little poor, will show this. This (in my opinion, before we get into another war of words) is why you find pigstickers with round bevels as the increased thickness of the steel in relation to the width needs more effort to lever off a flat bevel compared to a rounded bevel. Not because an old chippy decided a round bevel could be sharpened quicker than any other method. It's the adaptation of a tool to suit a particular task. Incoming...    |

|

|

|

Post by jfc on Jun 18, 2008 21:36:07 GMT

Who throw them rocks into your mortice hole !!!  I guess i should stop the never ending task to get them flat then ...... Phew ! Jacob , did you say you first saw a rounded bevel on a mortice chisel ...... i get lost in these threads as i dont give a monkeys what angle my chisels are as long as they are sharp ;D |

|

|

|

Post by jfc on Jun 18, 2008 21:39:08 GMT

Oh my , i think we have found the real reason for a rounded bevel and the fact that it does work  Can we all agree on that one ..............Pleeeeeeeeeeeeeeeease ;D Just thought , thats why they are called pig stickers ... You stick them in the mortice to hog out the sh*t . |

|

|

|

Post by andy king on Jun 18, 2008 21:48:09 GMT

Who throw them rocks into your mortice hole !!!  well i did say it was a crap drawing! I'm no good at these clever graphics programs, and drawing chips with Microsoft Paint ain't my strong point. Amateur at that as well! ;D Andy |

|

|

|

Post by davyowen on Jun 19, 2008 0:30:42 GMT

Sums things up nicely ;D |

|

|

|

Post by paulchapman on Jun 19, 2008 7:12:47 GMT

Oh my , i think we have found the real reason for a rounded bevel and the fact that it does work  Can we all agree on that one ..............Pleeeeeeeeeeeeeeeease ;D No, sorry ;D I've bought several second-hand pig stickers over the last couple of years. Two of them, which I hadn't used until now, had been honed with curved bevels by their previous owner, just like Jacob advocates. They are reasonably sharp so last night I tried them out, chopping a hole as you would with a mortice. Frankly, they were hopeless in comparison with my normally honed pig stickers. There were two problems. Although the edges were sharp, the overall shape of the curved bevels was quite blunt, so they didn't drive into the wood so easily (and I was giving them a good whack with a mallet). Second, the curve of the bevel tended to drive the chisels off-line, so they weren't so accurate. This probably wouldn't matter with a mortice, where you start at the centre and work backwards, but for other work it would. My overall conclusion is that curved bevels are a waste of time - inefficient, ineffective and inaccurate. Maybe the idea of easier leverage of chippings from the mortice was why curved bevels caught on with some people, but I'm certainly not going to start honing curves on my blades. Of course, Jacob could just be having a larf............ ;D Cheers  Paul |

|

|

|

Post by mrgrimsdale on Jun 19, 2008 7:17:49 GMT

Who throw them rocks into your mortice hole !!! I thought it was smoke from an over heated chiselYes - it was on a thread over there but most of it I deleted. I wasn't going to leave my pearls of wisdom behind if I was going to be banned. I'm not even allow to read, let alone write.   Happy Birthday ;D ;D cheers Jacob |

|

|

|

Post by mrgrimsdale on Jun 19, 2008 7:26:23 GMT

I've bought several second-hand pig stickers over the last couple of years. Two of them, which I hadn't used until now, had been honed with curved bevels by their previous owner, just like Jacob advocates. They are reasonably sharp so last night I tried them out, chopping a hole as you would with a mortice. Frankly, they were hopeless in comparison with my normally honed pig stickers. There were two problems. Although the edges were sharp, the overall shape of the curved bevels was quite blunt, so they didn't drive into the wood so easily (and I was giving them a good whack with a mallet). Second, the curve of the bevel tended to drive the chisels off-line, so they weren't so accurate. This probably wouldn't matter with a mortice, where you start at the centre and work backwards, but for other work it would. My overall conclusion is that curved bevels are a waste of time - inefficient, ineffective and inaccurate. Maybe the idea of easier leverage of chippings from the mortice was why curved bevels caught on with some people, but I'm certainly not going to start honing curves on my blades. Of course, Jacob could just be having a larf............ ;D Cheers  Paul By blunt bevel do you mean that the edge angle was steeper than your other chisels? Otherwise I can't see what blunt bevel could mean. Surely an all flat bevel would be even blunter i.e. having least amount of metal removed for a given edge angle? Can't see why I would make any difference in accuracy either, compared to a straight, double or hollow ground bevel. Got any snaps? chers Jacob |

|

|

|

Post by paulchapman on Jun 19, 2008 7:42:47 GMT

By blunt bevel do you mean that the edge angle was steeper than your other chisels? Otherwise I can't see what blunt bevel could mean. Surely an all flat bevel would be even blunter i.e. having least amount of metal removed for a given edge angle? Can't see why I would make any difference in accuracy either, compared to a straight, double or hollow ground bevel. Got any snaps? chers Jacob[/quote] Sorry, I didn't take any snaps. The chisel was quite sharp - it's just that the shape is all wrong with a curved bevel. Trying it out has convinced me that the curved bevel thing simply doesn't work (at least for me - but you carry on if you wish ;D). Cheers  Paul |

|

|

|

Post by paulchapman on Jun 20, 2008 15:56:03 GMT

Hi Jacob, I've been taking a few photos today, so here are a couple of the two mortice chisels honed into a curve, which I wasn't very impressed with   They had been honed like that by the previous owner and were reasonably sharp. I won't be keeping the curves when I re-hone them ;D Cheers  Paul |

|

|

|

Post by derekcohen on Jun 20, 2008 16:36:38 GMT

Hi Paul Compare those bevels with these three:  Your chisels appear to be ground and honed at about 30 degrees. Mine are ground at 20 degrees with a small 35 degree secondary bevel, a traditional set up for oval bolstered mortice chisels. It is fairly obvious which will penetrate more easily. Regards from Perth Derek |

|

|

|

Post by paulchapman on Jun 20, 2008 16:39:30 GMT

It is fairly obvious which will penetrate more easily. Hi Derek, I agree - but Jacob doesn't ;D Cheers  Paul |

|

|

|

Post by mrgrimsdale on Jun 20, 2008 17:05:39 GMT

They do look a bit chunky Paul. Have you measured the angle at the edge? I bet it's more than 30 esp the bigger one.

Mine are inbetweeny - bevel starting at 30ish but rounding off to less. Not so fine as Dereks but finer than yours.

I guess Derek's 35 would make a better starting bevel - I'll try it out.

cheers

Jacob

|

|

|

|

Post by paulchapman on Jun 20, 2008 17:39:38 GMT

Hi Jacob, No I haven't tried to measure the angle - and I don't think I could with any accuracy. These two pig stickers look as though they were deliberately honed into a curve, rather than the curve being a result of inexperienced honing, because they are quite nicely done. I've therefore tried to understand why anyone would want to hone a chisel that way. Frankly, other than to assist in scooping out the bottom of the mortice, I can't think of any sensible reason. It seems to me that, because of the curve, the moment you try to chisel the wood, the curve behind the cutting edge gets in the way, either hampering the chisel's travel or deflecting it, which would lead to an inaccurate cut. Either way, I've concluded that curved honing is not for me. If you are getting good results, well good luck to you - you are clearly more skilful than me ;D Cheers  Paul |

|

|

|

Post by Alf on Jun 20, 2008 18:40:17 GMT

Frankly, other than to assist in scooping out the bottom of the mortice, I can't think of any sensible reason. Well that's one. Another is it's supposed to be that it helps "pop" the chips out. I'm... undecided. Cheers, Alf |

|

|

|

Post by paulchapman on Jun 20, 2008 19:07:16 GMT

I watched a DVD a few days ago by Frank Klausz, all about cutting M&Ts. The speed, efficiency and accuracy with which he chopped a mortice by hand, using a conventionally honed pig sticker has convinced me that there is really no need to worry about getting the chips out. It's more about technique, practice and a sharp chisel. I know he's been doing it for a few years, but it looked quite straight forward. Cheers  Paul |

|

|

|

Post by tellurian on Jun 21, 2008 22:31:52 GMT

I do have moments of self doubt believe it or not. Oh you have got to be joking. |

|

|

|

Post by mrgrimsdale on Jun 22, 2008 7:50:48 GMT

I do have moments of self doubt believe it or not. Oh you have got to be joking. Yebbut they never last long ;D ;D Heres a sharpening thought for the day: I just sharpened my opinel pen knife with a steel. Easy peasy, 10 secs max. The bevels are convex and the edge angle is indeterminate. But thats OK, it's sharp. Now if some prat had come along and persuaded all pen knife owners that bevels should be flat and have precise angles, then pen knife sharpening would become difficult. You'd need some sort of jig and other bits of kit. It'd take much longer as well. Well that's just about what's happened with woodworking, someone has come along and persuaded etc etc. Probably the same prats who sell all the extra kit!! As soon as you get away from this, and back to simple convex (and probably indeterminate) bevels, it suddenly becomes as easy as sharpening a penknife. cheers Jacob |

|