|

|

Post by Scrit on Aug 15, 2008 19:39:26 GMT

I thought I'd seen a lot of "interesting" techniques for wood machining, but this guy beats em all! Oh well, I suppose he was wearing his Norm-type safety specs....... And the title, well it made me feel that way ;D Anyone know a better candidate for a woodworking Darwin Award? Scrit |

|

|

|

Post by engineerone on Aug 15, 2008 19:52:21 GMT

you sure he is far enough up the evolutionary chain for a darwin   actually at the end i thought he had nicked one of jacobs spindle cutters ;D paul  |

|

|

|

Post by wizer on Aug 15, 2008 21:11:10 GMT

haha that scared the life out of me, I'm never getting of of those bad boys

|

|

|

|

Post by tusses on Aug 15, 2008 21:14:28 GMT

cool ! Thanks for the recommendation Scrit where can I get one ?   |

|

|

|

Post by Scrit on Aug 15, 2008 21:56:36 GMT

A Darwin Award? They'll be round shortly withj the wooden box, don't you worry ;D Oh, and was this one filmed in your shop?  |

|

|

|

Post by tusses on Aug 15, 2008 22:04:54 GMT

nope here's mine - ready to be chucked and a new one cut.  |

|

|

|

Post by dangerousdave on Aug 16, 2008 11:36:11 GMT

HOLY CR@P  Hope the camera man was wearing safety specs as well

|

|

|

|

Post by Scrit on Aug 16, 2008 13:05:09 GMT

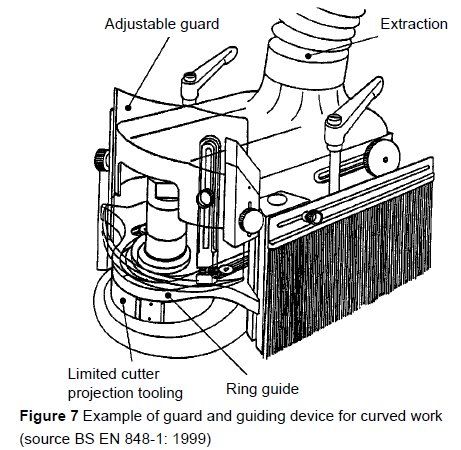

If you are unfamiliar with the processes and the safety required I'll give you a couple of pointers; using an inverted pin router, the first machine shown, to rough to an edge by doing a full height cut is not recommended - you get poor cutter life and breakages are far too common. The normal way is to rough-out on the bandsaw first then go straight to the spindle moulder (yes i know Onsrud say you don't have to, but they are also in the business of selling spiral solid carbide cutters). BTW, the same applies to overhead pin routers. The pin router was missing its bed insert as well. For crying out loud guys, the parts are only $4.50 a pop.  Secondly the spindle moulder was completely unguarded. Even in the USA they've heard of bonnet guards - I know, coz' I've seen them over there - so why no guard? Without a bonnet guard the jig holding the workpiece wouldn't have been much use in the event of separation from the material. So WTH kind of jig was that?  Oh, and I didn't mention the tooling. That amount of projection without limiters is a bit disconcerting as well. Especially without guards Ring fence/copy bearing work is probably the most frightening operation in the woodworking shop, but these guys seem not to give a damn about safety. Maybe even Norm could teach them a thing or two ;D I rather like the inverted pin router used for the first operation, but unless you use adequate jigging to hold the worl they are just as dangerous as the overhead pin router (and I know from personal experience how voracious their appetite is)  Samples of guarding and work holder (from HSE :Leaflet No. 18) give you some idea of what they should have been doing   Scrit PS Jason, it is necessary to stand by the machine whilst doing ring fence/copy bearing work..... So put away the broomstick and send the urchin machine operator home ;D |

|