|

|

Post by promhandicam on Oct 28, 2008 22:39:38 GMT

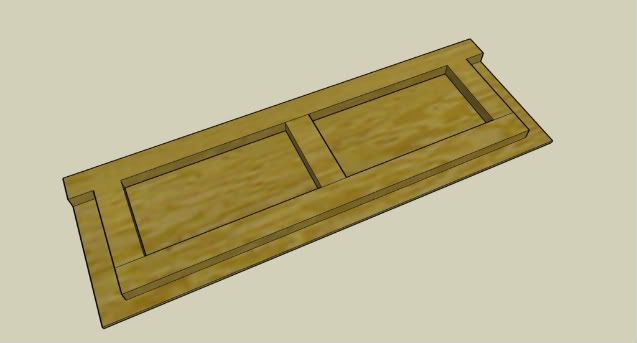

A while back I asked about wood for a cope and stick doors - well the job that they were for was finished today. In the end I went down the MR MDF route. I'm quite pleased with the finished result and so was the customer - they actually gave me more money than I'd quoted them.     In addition to making the cupboards and shelves I also redecorated the room. I tried to persuade them to get rid of the arches but they said they liked them. I think it would have looked better without them - perhaps putting a small false ceiling in so as to leave the cornice intact. The cupboards were primed in the workshop and then finished on site to match the walls. I used a small foam roller to apply the top coat (Dulux diamond eggshell) and was very pleased with the finish it gave. The shelves are 40mm thick - made from a sandwich of 9 and 6mm MR MDF with a filling of 25mm. Fixed by screwing 25mm battens to the wall (sides and back) and then sliding the shelf in. Fitting the cupboards was a bit tricky as they had to be free standing to allow access to the pipework for the gas fire / boiler. On the whole, it was a good learning experience and hopefully next time will be a bit more straight forward. Although I don't particularly enjoy the decorating side, at least I was able to offer the customer a complete package rather than just supplying the units and in the end it worked out well. I'd be interested to know what others do in this situation. Steve |

|

|

|

Post by Keith on Oct 29, 2008 7:50:04 GMT

Nice job, and they paid you more than you asked for!! Why don't I get customers like that? There is nothing wrong with the arches IMHO, it's the fireplace that is unfortunate. If I'm picky, which sadly I am  , I would have done the cupboard tops the same thickness as the shelves and I would have rounded over all the edges. Paint hates sharp edges and soon wears especially at the corners. I decorate sometimes when it is part of a bigger job, but usually quote separately for it. Otherwise they expect you to do it for nowt. Keith |

|

|

|

Post by paulchapman on Oct 29, 2008 8:37:22 GMT

Very nice job, Steve. Cheers  Paul |

|

|

|

Post by promhandicam on Oct 29, 2008 22:24:28 GMT

. . . . If I'm picky, which sadly I am  , I would have done the cupboard tops the same thickness as the shelves and I would have rounded over all the edges. Paint hates sharp edges and soon wears especially at the corners. I decorate sometimes when it is part of a bigger job, but usually quote separately for it. Otherwise they expect you to do it for nowt. Keith Thanks for the comments which I will try to remember for the next time  I agree with you that the top would look better if it were the same thickness as the shelves - I'd not thought of that before making it. When you say that you round over the edges, do you go as far as using a round over bit or do you just use a plane to know the corners off? Steve |

|

|

|

Post by mrgrimsdale on Oct 29, 2008 22:47:06 GMT

Looks good. I see no cope, or stick?

"Stick" means moulding direct to to stiles/rails as opposed to "planted" and "coped" is how you join the corners - along with "mitred". Various stages in between are possible.

|

|

|

|

Post by engineerone on Oct 29, 2008 22:56:49 GMT

nice work steve, and decent decorating too  i agree with keith about the cupboard top thickness, but it is often difficult to imagine it until it is in situ. as for rounding off the edges, veritas do a little tool which helps, or you can of course use a plane to take a small shaving off. with jacob's favourite material, a file is just as good. paul  |

|

|

|

Post by Keith on Oct 30, 2008 8:36:56 GMT

. . . . If I'm picky, which sadly I am  , I would have done the cupboard tops the same thickness as the shelves and I would have rounded over all the edges. Paint hates sharp edges and soon wears especially at the corners. I decorate sometimes when it is part of a bigger job, but usually quote separately for it. Otherwise they expect you to do it for nowt. Keith Thanks for the comments which I will try to remember for the next time  I agree with you that the top would look better if it were the same thickness as the shelves - I'd not thought of that before making it. When you say that you round over the edges, do you go as far as using a round over bit or do you just use a plane to know the corners off? Steve Steve I usually use a small radius rounding over bit in a laminate trimmer and all the edges get the treatment. Taking a few passes with a plane and sanding it round works but it isn't so consistent. |

|

|

|

Post by promhandicam on Oct 30, 2008 11:51:51 GMT

Looks good. I see no cope, or stick? "Stick" means moulding direct to to stiles/rails as opposed to "planted" and "coped" is how you join the corners - along with "mitred". Various stages in between are possible. Hi Jacob. The corners are joined with what I thought were a cope and stick joint, i.e. the rails and stiles were machined with a groove and then the ends of the rails were machined to form a tenon. The groove on these doors is 9mm wide to correspond with the 9mm thick mdf panel. Or perhaps this is a backhand complement in that you are obliquely saying that the doors are so well made you can't see any joins ;D Steve |

|

|

|

Post by modernist on Oct 30, 2008 20:21:45 GMT

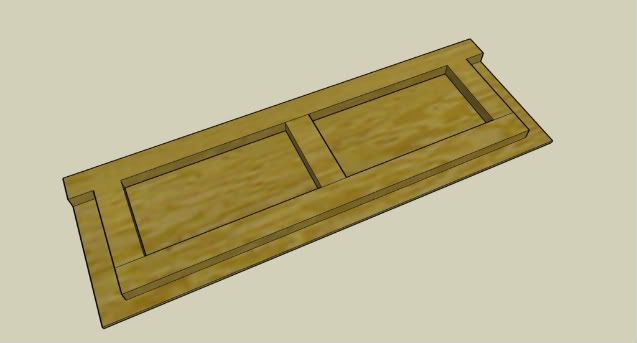

What "filling" did you use in the shelves? and what glue/method.

I recently did some 10/25/10 door panels in T & G douglas fir with 25mm foil covered PU foam between. Had glue problems.

Brian

|

|

|

|

Post by mrgrimsdale on Oct 30, 2008 21:38:36 GMT

Looks good. I see no cope, or stick? "Stick" means moulding direct to to stiles/rails as opposed to "planted" and "coped" is how you join the corners - along with "mitred". Various stages in between are possible. Hi Jacob. The corners are joined with what I thought were a cope and stick joint, i.e. the rails and stiles were machined with a groove and then the ends of the rails were machined to form a tenon. The groove on these doors is 9mm wide to correspond with the 9mm thick mdf panel. Or perhaps this is a backhand complement in that you are obliquely saying that the doors are so well made you can't see any joins ;D Steve Cope and stick is having a moulding "stuck" on the edge which is then "coped" or scribed at the joints. en.wikipedia.org/wiki/Cope_and_stickSo yours isn't, though it is well made! It's just terminology. Depends on your kit but I find it easier to cut all mortices, and tenon cheeks only before doing the slot, or mouldings. Tenon shoulders last. cheers Jacob |

|

|

|

Post by promhandicam on Oct 30, 2008 23:34:09 GMT

What "filling" did you use in the shelves? and what glue/method. I recently did some 10/25/10 door panels in T & G douglas fir with 25mm foil covered PU foam between. Had glue problems. Brian This is how I made the shelves - top removed for clarity ;D This is looking on from the rear.  The filling is 25mm MDF and the front piece was flush with the top and bottom panels. Glued using titebond original and clamped up using about 15 clamps. When I installed it, the 9mm panel was on the top, although I don't think it would really have made a lot of difference. Hope this helps, Steve |

|

|

|

Post by promhandicam on Oct 31, 2008 0:01:03 GMT

Cope and stick is having a moulding "stuck" on the edge which is then "coped" or scribed at the joints. en.wikipedia.org/wiki/Cope_and_stickSo yours isn't, though it is well made! It's just terminology. Depends on your kit but I find it easier to cut all mortices, and tenon cheeks only before doing the slot, or mouldings. Tenon shoulders last. cheers Jacob I think that this maybe another example of the same terms being used for different things depending on which side of the atlantic (or pennines) you come from. In my original post about cope and stick doors Jason gave a link to Jeff Greef's Curved cope and stick joinery web page. There Jeff says, "'COPE AND STICK' JOINERY (or 'stile and rail') is a very common means of making wood frames for glass or wood panels. Perhaps what I should have referred to was panel doors with scribed rails. In the end, because the customer wanted 'shaker' style doors, there was no moulding as such so no profile was formed on the rails and stiles. The only thing 'stuck' on my doors was the panel in the grooves and the stiles to the rails  Steve |

|

|

|

Post by mrgrimsdale on Oct 31, 2008 6:20:13 GMT

J Greef is talking about the same thing. Without mouldings and scribed (or "coped") joints it is no longer "cope and stick".

Your doors are just plain panel doors which isn't really a style of any sort. It's just the most common way of making doors, windows, panels etc. Usully with haunched M&T joints and stub tenons for muntins. nb "Muntin" is something else in America so thats potentially confusing too.

nb the panels aren't supposed to be "stuck" The whole point of panel construction is to have a free floating panel to avoid structural movement.

cheers

Jacob

|

|

|

|

Post by promhandicam on Oct 31, 2008 18:17:43 GMT

. . . nb the panels aren't supposed to be "stuck" The whole point of panel construction is to have a free floating panel to avoid structural movement. cheers Jacob Quite true if using wood but with mdf I dont' think it is an issue - it actually makes the door stronger as the stiles don't have 'proper' tenons. This is the advice given here by other MDF aficionados  Steve |

|

simuk

Full Member

Posts: 111

|

Post by simuk on Oct 31, 2008 18:36:58 GMT

Yep looks all white  |

|

, I would have done the cupboard tops the same thickness as the shelves and I would have rounded over all the edges. Paint hates sharp edges and soon wears especially at the corners.

, I would have done the cupboard tops the same thickness as the shelves and I would have rounded over all the edges. Paint hates sharp edges and soon wears especially at the corners.