Post by promhandicam on Nov 13, 2008 22:40:52 GMT

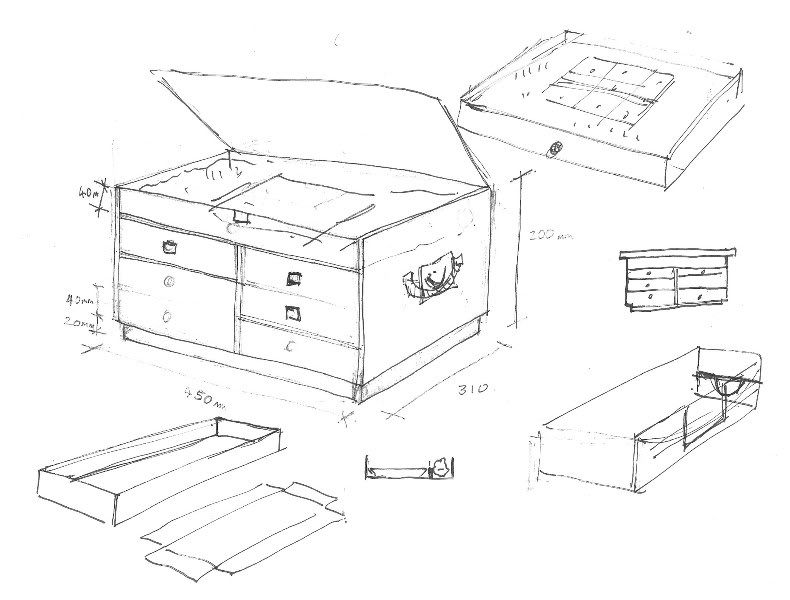

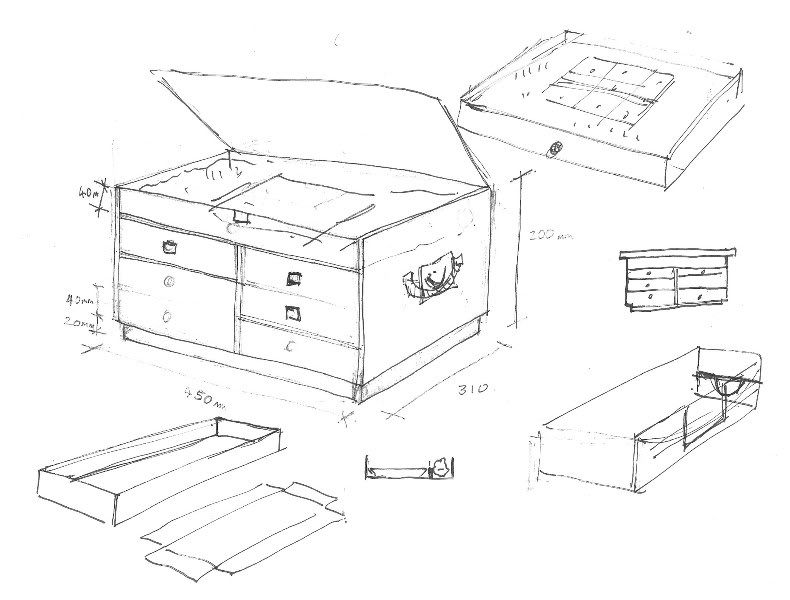

Last wednesday I got a call from a friend asking if I would be able to make a case out of solid wood for a client of his. He had done the following sketch -

The 6 small drawers each had to hold an oblong plate and napkin. The larger drawer was going to have a puzzle fitted into it. The only problem was that the client wanted it done by this wednesday They also wanted it as small and light as possible as someone was going to have to carry it into the boardroom for the presentation. Thankfully SL Hardwoods had some wide oak boards in stock so as I was going there anyway on Friday I picked up 3 boards from them

They also wanted it as small and light as possible as someone was going to have to carry it into the boardroom for the presentation. Thankfully SL Hardwoods had some wide oak boards in stock so as I was going there anyway on Friday I picked up 3 boards from them

Saturday was spent making 3 sacks of chippings and joining up the large panels for the top bottom and sides, and Sunday the large drawer was made and finished as it was needed by another company Monday to do the puzzle.

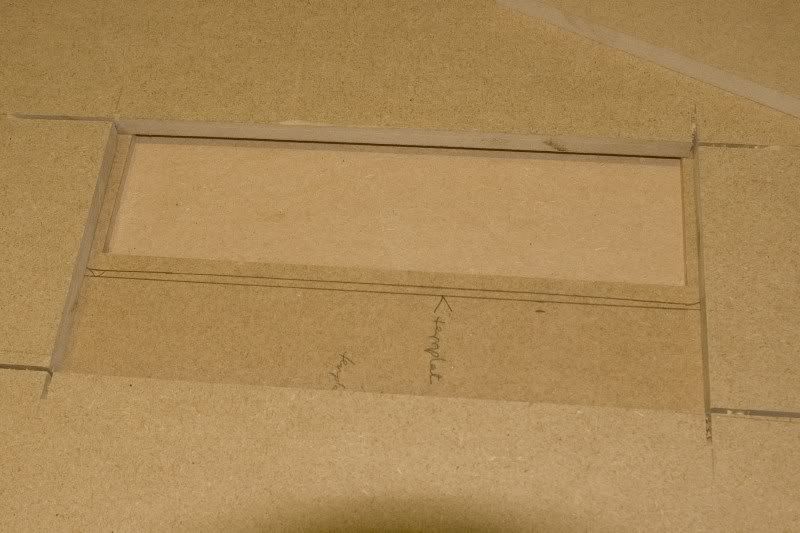

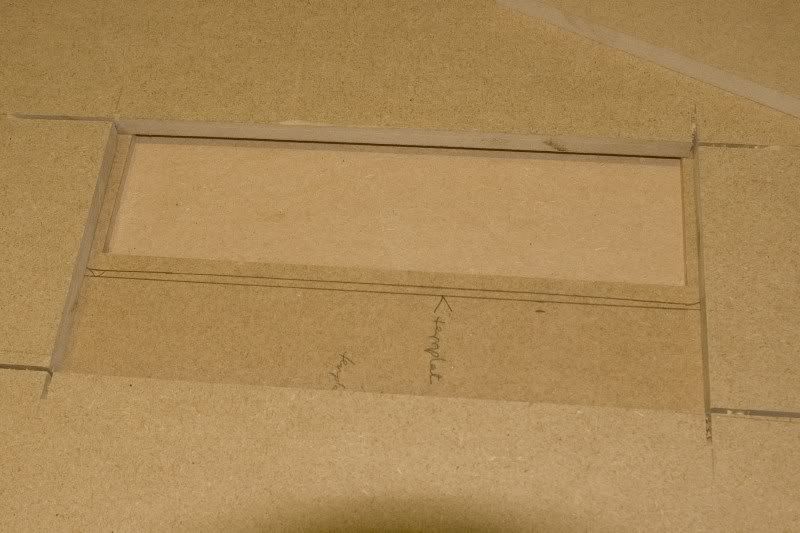

To keep the size down, I came up with the idea of using some 10mm x 10mm x 1mm aluminium angle for the runners and dusted off my worktop jig to rout the rebates that they would be glued into.

To make the indentation for the plates and napkins to sit in I made up a template and a large sub base for the router - the festool plunge saw/guide rail is excellent for making an accurate cut out for the template.

First one done

By Monday night I had all the components made and so was able to start on the assembly and finishing Tuesday.

So that the drawers ran smoothly and didn't jam I put a self adhesive felt pad next to the drawer slide which worked really well.

In view of the fast approaching deadline, and the fact that the thing was going to be used for presenting food, I opted for a couple of coats of briwax which doesn't smell too much.

The finished article was delivered on schedule at 10am yesterday.

Given the very short time scale and the constraints made by the designer, I am really happy with the outcome. More importantly the client was very happy too. I did explain that because of the way they wanted it constructed - with the end grain showing - that I couldn't guarantee it wouldn't warp - and they were happy with this.

I did explain that because of the way they wanted it constructed - with the end grain showing - that I couldn't guarantee it wouldn't warp - and they were happy with this.

As usual, any comments / advice appreciated.

Steve

The 6 small drawers each had to hold an oblong plate and napkin. The larger drawer was going to have a puzzle fitted into it. The only problem was that the client wanted it done by this wednesday

They also wanted it as small and light as possible as someone was going to have to carry it into the boardroom for the presentation. Thankfully SL Hardwoods had some wide oak boards in stock so as I was going there anyway on Friday I picked up 3 boards from them

They also wanted it as small and light as possible as someone was going to have to carry it into the boardroom for the presentation. Thankfully SL Hardwoods had some wide oak boards in stock so as I was going there anyway on Friday I picked up 3 boards from them

Saturday was spent making 3 sacks of chippings and joining up the large panels for the top bottom and sides, and Sunday the large drawer was made and finished as it was needed by another company Monday to do the puzzle.

To keep the size down, I came up with the idea of using some 10mm x 10mm x 1mm aluminium angle for the runners and dusted off my worktop jig to rout the rebates that they would be glued into.

To make the indentation for the plates and napkins to sit in I made up a template and a large sub base for the router - the festool plunge saw/guide rail is excellent for making an accurate cut out for the template.

First one done

By Monday night I had all the components made and so was able to start on the assembly and finishing Tuesday.

So that the drawers ran smoothly and didn't jam I put a self adhesive felt pad next to the drawer slide which worked really well.

In view of the fast approaching deadline, and the fact that the thing was going to be used for presenting food, I opted for a couple of coats of briwax which doesn't smell too much.

The finished article was delivered on schedule at 10am yesterday.

Given the very short time scale and the constraints made by the designer, I am really happy with the outcome. More importantly the client was very happy too.

I did explain that because of the way they wanted it constructed - with the end grain showing - that I couldn't guarantee it wouldn't warp - and they were happy with this.

I did explain that because of the way they wanted it constructed - with the end grain showing - that I couldn't guarantee it wouldn't warp - and they were happy with this.As usual, any comments / advice appreciated.

Steve