|

|

Post by mrgrimsdale on Nov 29, 2008 8:57:01 GMT

Just looking at tenoning on a table saw. All guarding necessary will be in place!

This for longish rails, so a simple push stick variation no good. It has to be firmly held.

Simplest seems to be the saddle carriage sitting on the fence, which is conveniently adjustable.

But the sliding table should be safer and steadier. I can sort something out, but a few

pointers could be helpful. No point in reinventing the wheel.

Any neat designs, bright ideas, out there?

PS I used to do it on the band saw but it was never satisfactory. Am also looking at over the spindle cutters - any particular recommendations on that? What about a countersunk bolt in the top of a rebate block?

|

|

|

|

Post by tusses on Nov 29, 2008 10:54:48 GMT

nibble or dado  this is a 7x2 x4' on a full slider cutting the shoulders  this one , on a half slider being 'nibbled'  |

|

|

|

Post by mrgrimsdale on Nov 29, 2008 11:09:57 GMT

nibble or dado  Neither. Am looking for best holding device for piece held vertical for cutting cheeks. Cheap fast accurate I hope:o Don't want to spend on a tenon block etc. |

|

stevep

Junior Member

Posts: 63

|

Post by stevep on Nov 29, 2008 13:16:48 GMT

I made a saddle to fit over the existing fence, with the base sliding on the table surface for cutting cheeks. It was rubbish - far too much wobble which meant the cheeks weren't parallel. I also made a sliding table for cutting the shoulders, which was ok.

The other problem with cutting the cheeks with the wood vertical is that the grain direction is different to ordinary ripping - my rip blade made heavy weather of it, so you might need a blade

with a different rake angle or tooth shape.

In the end I gave up and made a really accurate tall fence for the bandsaw from some laminate faced board (a bit like an engineers angle plate*), made sure the face was exactly vertical and just clamped it onto the table. I set it up with the digital calipers. I cut the shoulders on the RAS with a stop clamped on the fence so I don't have to mark each one.

If it's a haunched tenon or I'm going to wedge it, I go back to the bandsaw and just use the normal fence in the normal way.

* There's a thought - maybe an angle plate is the ultimate answer. Axminster do a 100mm one for £13.

|

|

|

|

Post by jasonb on Nov 29, 2008 13:37:25 GMT

The CSK screw in a spindle block will only work if your block has a CSK hole like this one. Which is best retained with a CSK "washer" thats counterbored for a cap screw. I have use a simple "L" shaped sledge with a couple of diagonals to keep it at 90deg that slips over the rip fence, a batten at the back will keep the work alighned the other way then just clamp the work to it. Tend to use the bandsaw mostly now and just clean up with a sholder plane if needed. Jason |

|

|

|

Post by tusses on Nov 29, 2008 14:34:26 GMT

nibble or dado  Neither. Am looking for best holding device for piece held vertical for cutting cheeks. Cheap fast accurate I hope:o Don't want to spend on a tenon block etc. oh ... a, la, Norm ;D check out Mailee's big gate thread - he used one  |

|

|

|

Post by tusses on Nov 29, 2008 14:53:59 GMT

I made one for my old TS - I'll get some pics up later

|

|

|

|

Post by tusses on Nov 29, 2008 15:48:24 GMT

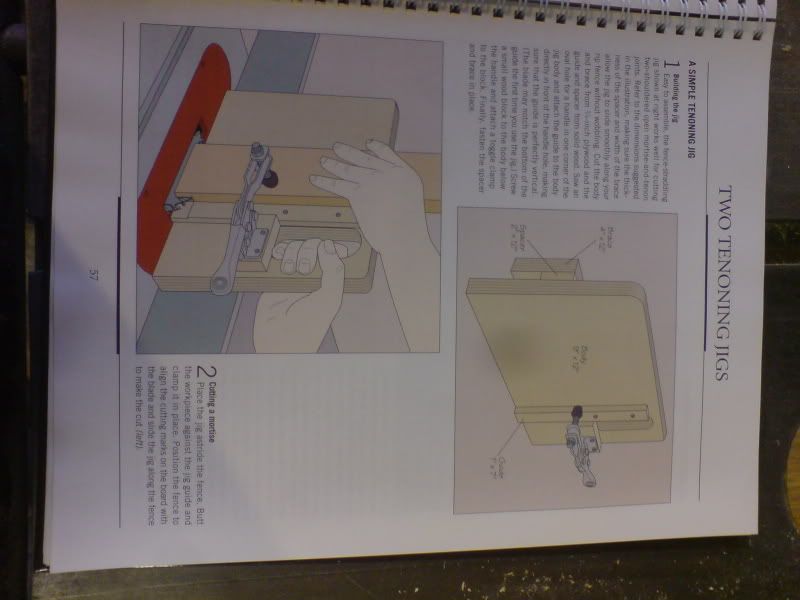

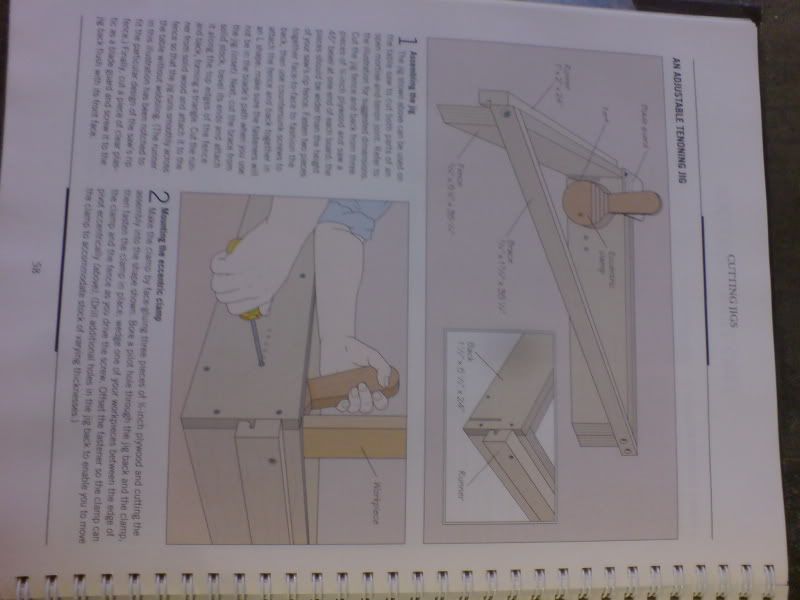

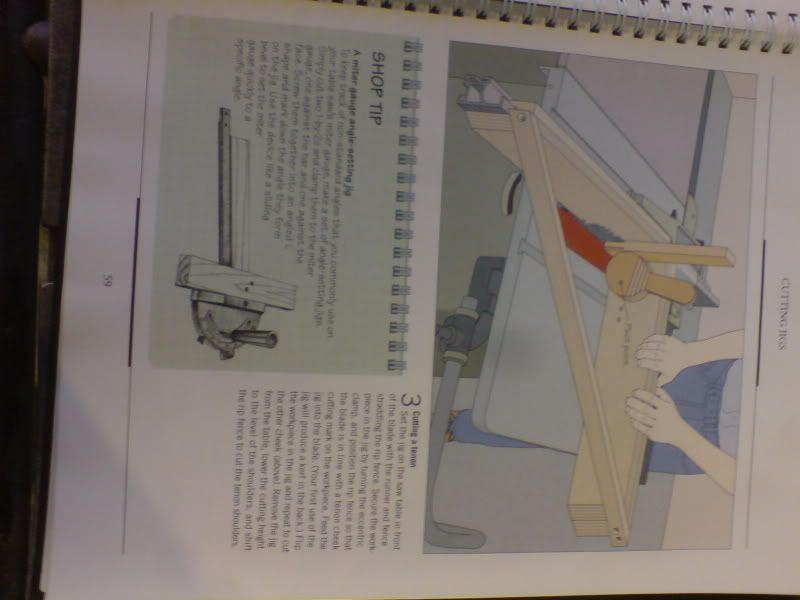

this is a simple one, saddles the fence  this is the one I made and used with good results   is you want pics to read the text, let me know |

|

stevep

Junior Member

Posts: 63

|

Post by stevep on Nov 29, 2008 16:24:42 GMT

this is a simple one, saddles the fence.... Yes, that's the same as the one I tried out. It doesn't have enough stability to be accurate. The other one you picture looks as though it would be a lot better - apart from the blade/grain direction problem that might involve buying a different blade. Cutting a haunch would mean turning the job round, and cutting another kerf through the back support piece. I still think the bandsaw is the best option for cutting the cheeks though - with a decent 3/4" blade it's accurate and leaves a finish that is fine for glueing. |

|

|

|

Post by tusses on Nov 29, 2008 17:17:16 GMT

after a few different tennons, the back piece gets a bit chewed up, but as long as its high enough it doesn't matter.

|

|

|

|

Post by mrgrimsdale on Nov 29, 2008 18:01:54 GMT

Thanks for that. stevep yes the saddle too unstable. For me bandsaw OK but only if very new blade. I am hoping for an accurate reliable system which costs f.a. and will do 20 in a row without needing any fettling. jasonb settled on L shaped sledge so far tusses very clever that last one in the book! wish I'd thought of that. It turned out simpler than I expected, L shaped sledge. 2 bits of 2x4 and an mdf bracket:  The workpiece clamped but the whole thing hand-held against fence on sliding table;   Width set against mortice guage marks on a bit of scrap;  height set against pencil marks;  Tilt either by tilting saw blade or shimming the bracket. Seems OK so far |

|

|

|

Post by mrgrimsdale on Nov 29, 2008 19:16:42 GMT

Felder video recommends a 'slotting' saw for this job. Seems to be slightly wider than a rip and has square across teeth like a rip filed hand saw. Would this make much difference? They also say use a riving knife but set below the crown, so that's on my list too

|

|

stevep

Junior Member

Posts: 63

|

Post by stevep on Nov 29, 2008 20:05:34 GMT

The last job I did was 12 tenons in 4 and 6" softwood, well 13 actually as I did a test piece on some scrap to set it up right - no fiddling round with a shoulder plane, all of them perfect size. That was with a new blade. Having looked at your rails, I couldn't do them on my saw bench - no headroom!

I don't know enough about blades to give a verdict on the Felder suggestion. My 24t rip blade generated a lot of smoke and needed a higher feed pressure last time I tried to cut this way - thinking it was just blunt I tried both ripping and cross cutting afterwards, and it was fine. Experimenting with a tenon saw, I think that it's easier to make ripping cut with the blade going straight across the grain - inclining the blade so it's closer to being parallel to the grain makes it cut slower. Maybe the shavings clog up the gullets a bit more. You've got rakers on your blade by the look of it, so perhaps thats got something to do with it as well.

Any road up, it looks like you got it sorted out well enough.

|

|

|

|

Post by jfc on Nov 29, 2008 20:06:19 GMT

OOOOOOOOOOOOOOOOOOOOOOOOO you big fat liar !!!!!! ;D I asked this question ages ago and you swore by the bandsaw even though i said i was having problems getting them perfect . When i said i have started to clean them up with a router you said why bother , they come off your bandsaw perfect ! You even took the piss out of the jigs i made to get over the thing you didnt see as a problem  You have soooooo been caught out bullshitting ;D Its soooo funny !!! ;D |

|

|

|

Post by mrgrimsdale on Nov 29, 2008 20:18:18 GMT

;D I can change my mind can't I?

I was just trying to be optimistic and encouraging ;D

Bandsaw is OK with new blade, well perfect in fact ;D but I can't get one til late next week so I'm trying this. Bandsaw blade does deteriorate fairly quickly, and need a bit of a fettle sometimes on tenons, I must say.

|

|

|

|

Post by wizer on Nov 29, 2008 20:24:45 GMT

no one actually listens to Jacob do they??  |

|

|

|

Post by mailee on Nov 29, 2008 20:40:46 GMT

Ok as lo ng as no one takes the 'P' and Scrit doesn't damn me to hell, here is my tennoning jig for the table saw:  I find this pretty stable with lengths up to 24"after that I close my eyes. ;D |

|

|

|

Post by mrgrimsdale on Nov 29, 2008 20:48:20 GMT

Ok as lo ng as no one takes the 'P' and Scrit doesn't damn me to hell, here is my tennoning jig for the table saw: ![]() I find this pretty stable with lengths up to 24"after that I close my eyes. ;D Oh yes I remember seeing it before (and being a bit rude about it sorry mailee ;D) Mine's much the same but with the sliding table I can do longer lengths as it's steadier. What I'm after is that perfect clunk click everytime with no fettling. I'm trying to improve my act across the board (woodwork only ;D) as I get in to new projects. |

|

|

|

Post by sainty on Nov 29, 2008 21:29:29 GMT

I used something similar once, but i have to say I wasn't sure about the safety aspect of it.

Jacob, I think you said you had a wobble saw for the spindle? I think it would be safer to set the wobble to zero wobble and use a sliding carriage on the spindle. I think it would be better to have the timber clamped horizontally on the carriage rather than swinging around in the air. It's probably easier to make adjustments to the width of the tenon too (rise and fall adjustment rahter than nudging your jig).

The question is, do you use an unguarded table saw to cut the shoulder?

rgds

Stu

Edit: Probably restricted a bit on the depth of cut.

|

|

|

|

Post by mrgrimsdale on Nov 29, 2008 23:09:46 GMT

Wobble saw brill but too short reach for tenons. I wondered about putting a 10" saw-blade on the spindle but it looks a bit reckless, but why not, with suitable guarding?

Yes to unguarded table saw to cut the shoulder, but I do take care.

|

|

|

|

Post by mel on Nov 30, 2008 7:59:12 GMT

Just looking at tenoning on a table saw. All guarding necessary will be in place! Jacob you wont be able to do it with the crown guard in place , no matter how you try. have you got a "T" slot in the table top ?? for making gates with 4" tennons i use a sledge mounted in the "t" slot . crown guard removed {there i said it} if you cut the tennon first , then make the shoulder cuts there is no offcut to fall into the saw blade its about the safest way of doing it but still not perfect ill put a photo up later , |

|

|

|

Post by mrgrimsdale on Nov 30, 2008 10:25:40 GMT

Have sliding table, even better than T slot. See photos above. It's safe in operation - hands well away from the blade, but the hazard is the unattended exposed blade if you are distracted doing something else. Could add a moving crown guard I suppose.

Maybe I'll just fork out the cash and buy tenoning head for the spindle instead! Still a fearsome thing though, it has to stick out the same amount

|

|

|

|

Post by mrgrimsdale on Nov 30, 2008 16:36:19 GMT

Getting nearer - spindle rebate block does very trim tenon, why didn't I try this first? But it's too short so I need a CSK top bolt. Looks like axminster is the best option - if my time is worth anything at all. To be updated when it's paid for itself, with this or similar. Only prob is the spelch out which will need a chisel cut or something. |

|

|

|

Post by jasonb on Nov 30, 2008 17:54:13 GMT

Back the work with a piece of scrap to stop spelch

Jason

|

|

|

|

Post by mrgrimsdale on Nov 30, 2008 18:24:26 GMT

Getting nearer - spindle rebate block does very trim tenon, why didn't I try this first? But it's too short so I need a CSK top bolt. Looks like axminster is the best option - if my time is worth anything at all. To be updated when it's paid for itself, with this or similar. Only prob is the spelch out which will need a chisel cut or something. Or, does anyone know of a normal rebate block with scribing cutters, with a csk hole/bolt. Or would it be worth taking my existing block to an engineer to machine a countersink? |

|