|

|

Post by jasonb on Nov 30, 2008 18:52:34 GMT

Wealden & record do universal blocks with csk fixing that take the disposable TCT knives & scribers as well as being able to use them with 40mm euro profile knives, see the link in my first post.

You will need to source a csk washer and suitable bolt as the usual M12 or M14 csk cap screws do not have a large enough head.

I'd just stick it in my engineering lathe and modify it for you if you were nearer.

Jason

|

|

|

|

Post by jonnyd on Nov 30, 2008 18:59:33 GMT

I have a pair of those whitehill blocks for my tenoner the standard bore is 1 1/4 inch the threaded boss in the middle allows it to be flush mounted on the tenoners 20mm (i think) spindle. I dont think you would be able to flush mount in on a spindle moulder without some engineering work. It might be worth ringing whitehill and asking them about it as they are usually very knowledgable and helpfull (if you get the right person) or may have a part to convert it to your spindle size.

jon

|

|

|

|

Post by modernist on Nov 30, 2008 20:53:03 GMT

Getting nearer - spindle rebate block does very trim tenon, why didn't I try this first? But it's too short so I need a CSK top bolt. Looks like axminster is the best option - if my time is worth anything at all. To be updated when it's paid for itself, with this or similar. Only prob is the spelch out which will need a chisel cut or something. Or, does anyone know of a normal rebate block with scribing cutters, with a csk hole/bolt. Or would it be worth taking my existing block to an engineer to machine a countersink? I've got a metalwork lathe arriving here next Tuesday - feel free. I suggest we discuss it over a beer. Problem is I am moving my folks down to Duffield next week (hence the lathe) but as soon as I surface off we go. cheers Brian |

|

|

|

Post by mrgrimsdale on Nov 30, 2008 21:06:07 GMT

Or, does anyone know of a normal rebate block with scribing cutters, with a csk hole/bolt. Or would it be worth taking my existing block to an engineer to machine a countersink? I've got a metalwork lathe arriving here next Tuesday - feel free. I suggest we discuss it over a beer. Problem is I am moving my folks down to Duffield next week (hence the lathe) but as soon as I surface off we go. cheers Brian OK Brian yer on! If you need a hand shifting stuff give me a call. I'm off to LM Saws tomorrow for bandsaw blades so will have a look at what they offer |

|

jrm

New Member

Posts: 17

|

Post by jrm on Nov 30, 2008 21:23:37 GMT

Hi Jacob, I've tried most methods to produce tenons. I found tenoning one side at a time had problems. 1. it's necessary to reference from two different faces which invites inaccuracy. 2. Unless the tenon is central, you have another setup to go through to get the thickness right. 3. However, the main problem I found was because of small inconsistencies in the timber. Unless jointing is done pretty quickly after planing, even a small amount of cupping/curving, etc. will alter the position of the tenon and this won't be consistent from side to side so you end up with inconsistent thicknesses. Of course, it depends on what sort of timber you are using but in a pretty dense hardwood, it's surprising what a difference the smallest dicrepancy can make to the fit. I've used this with success:  The cutters are adjustable groovers with spacers between. Clearly this isn't enough for your purposes and you would need something with a much larger diameter. With this sort of setup, any slight discrepancy in position doesn't effect the thickness. I have used a sawblade on the spindle (230mm x 4mm) but I found this flexed too much. Maybe if you used two? I just think, if you're going to the trouble and expense, you certainly don't want to be bu***ring about with a shoulder plane to make half of them fit properly. As I say, it depends on what timber you are using. Incidentally, in the example shown, a piece of hardwood is bolted to the crosscut fence which takes of spelch nicely but has be accurately prepared. Having said all that, if I only have say four to do, I have cut the shoulders on the table saw and the cheeks on the bandsaw, using a carefully prepared spacer I keep handy so that the face side can be against the fence for both cuts, re-using as often as you like as long as you use the same type of blade. John |

|

|

|

Post by modernist on Nov 30, 2008 22:31:47 GMT

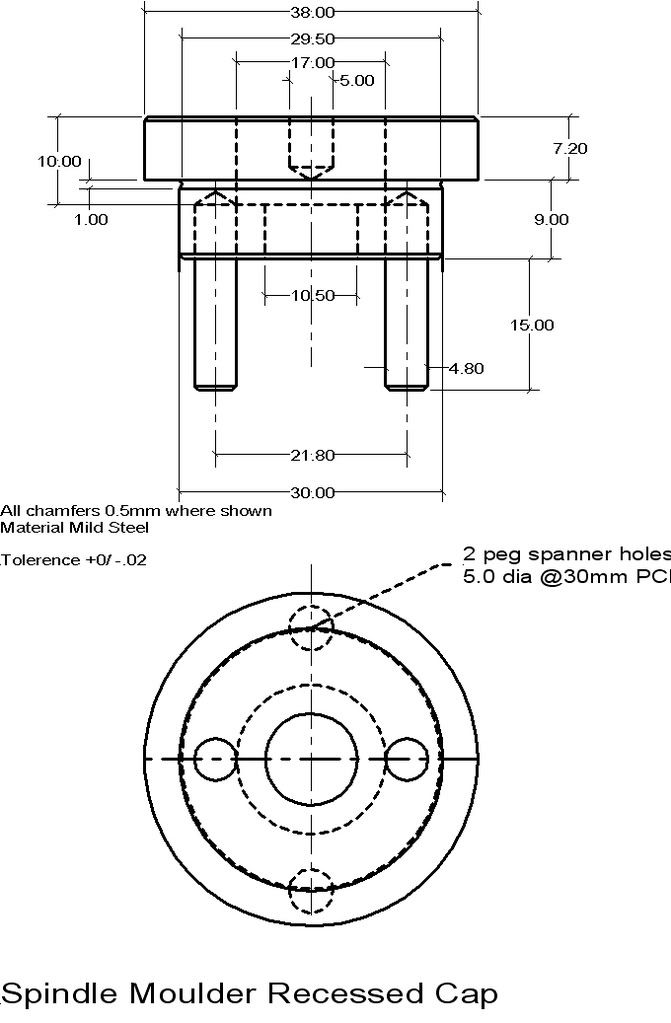

I've got a metalwork lathe arriving here next Tuesday - feel free. I suggest we discuss it over a beer. Problem is I am moving my folks down to Duffield next week (hence the lathe) but as soon as I surface off we go. cheers Brian OK Brian yer on! If you need a hand shifting stuff give me a call. I'm off to LM Saws tomorrow for bandsaw blades so will have a look at what they offer This was mine from an old thread At the time I could not get a block that would also take a recessed head for a Felder/Hammer spindle so ended up making a cap myself for the block.   and tennoning  This works fine with the Axminster block All royalties in pints of Bass please. Brian |

|

|

|

Post by jfc on Nov 30, 2008 22:34:11 GMT

I have this block you are welcome to try   Your welcome to try it out before you commit to buying anything . Mine isnt for sale BTW . |

|

|

|

Post by woodworker on Nov 30, 2008 23:25:50 GMT

|

|

|

|

Post by mrgrimsdale on Nov 30, 2008 23:26:25 GMT

Thanks Jason. Kind of you but it's OK I've made my mind up after wandering about a bit - that's what I need anyway. Until I get a proper 2 headed tenonner.

Thanks all for the useful advice.

cheers

Jacob

|

|

|

|

Post by mrgrimsdale on Nov 30, 2008 23:30:46 GMT

Kinell this last post crossed with woodworker's snaps! Closer look in the morning. Just had several whisky macs - medicinal I've got a cold. Mrs G says she has too, lying old bat!

|

|

|

|

Post by jfc on Nov 30, 2008 23:36:00 GMT

I think mine is an old wadkin block that takes saw blades aswell as cutters  Scares the sh*t out of me ! |

|

|

|

Post by mrgrimsdale on Dec 2, 2008 21:34:18 GMT

bin around the block and back again.

Over the TS - no good, just not accurate enough, quicker to nibble. And yes to jrms comments about losing accuracy if you don't do it pronto.

What I want is woodworkers combi head - but the hole is too small on my stupid machine - 125 dia 42 deep. I hadn't noticed this when I bought it (minimax lab300 combi) or I wouldn't have bothered. So am considering a small rebate block, to be adapted with a csk bolt.

So it's back to the bandsaw. See I was right first time jason!

Bandsaw means following gauge lines - I set the fence so that the bottom cuts right, and then guide the top, if necessary.

Will carry on this way until project makes huge profit and I buy a 2 head tenonner!

|

|

|

|

Post by jfc on Dec 2, 2008 21:46:27 GMT

Well i know you dont like routers but if i need the tenon to be perfect i rough it on the bandsaw and use a small router that i have made an extended base for . I can hold that base on the timber and swing the router over the tenon cleaning it up . Flip the timber over and do the same on the other side . Its just a really cheap router set up just to do that task so is very quick to do , you just need to clean up the shoulder edge with a chisel but again that takes seconds .

|

|

|

|

Post by jonnyd on Dec 2, 2008 22:02:41 GMT

I have tried all manner of methods for cutting tenons myself including bandsaw, table saw, router table and spindle and each one has its pros and cons. My setup know includes a single ended tenoner with a couple of whitehill combi heads that will tenon and scribe in one pass quickly and accurately once setup this method is 3 or 4 times quicker than any of the other methods.

jon

|

|

|

|

Post by engineerone on Dec 2, 2008 22:28:41 GMT

why not use a development of what jason has said.  make a three sided box of hardwood, with a base of you favourite material jacob, mdf. the sides should be about 1inch higher than your normal material. make a carrier for the router and then put a stop on the sides. you can then rout the tenon to a specific length and depth using a flat bottomed bit with an up cut. you can also use the jig for routing the pieces to length, and even for making mortices too. paul  |

|

|

|

Post by lynx on Dec 2, 2008 23:13:54 GMT

MrG, why not have a look at these www.whitehill-tools.com/TenonDiscs.aspxI bought a 225mm diameter, and with the cutters will tenon 110mm (tight) and these can be stacked also. I did take most of the waste out quickly on the bandsaw and clean up with a few passing with one of these. |

|

|

|

Post by mrgrimsdale on Dec 3, 2008 9:20:21 GMT

MrG, why not have a look at these www.whitehill-tools.com/TenonDiscs.aspxI bought a 225mm diameter, and with the cutters will tenon 110mm (tight) and these can be stacked also. I did take most of the waste out quickly on the bandsaw and clean up with a few passing with one of these. Yes I think you are right. I was looking for a cheaper middle way. Why are you band-sawing too? Won't these cutters do it in one pass? |

|

|

|

Post by lynx on Dec 4, 2008 18:14:24 GMT

it helped with extraction too. I'm using it with the bolt on tenon carriage and you can't really got the extractor connected to take out the waste, so reducing the material reduced the dust.

Plus i was shitting it, so chicken out. I'm not sure if you can do this in one, can you?

|

|

|

|

Post by mrgrimsdale on Dec 5, 2008 17:36:34 GMT

snip I'm not sure if you can do this in one, can you? That's the whole idea as far as I'm concerned - either 2 passes over one csk rebate block, or one pass between stacked cutters. Otherwise I might as well stick with the bandsaw, with TS for shoulders, as I have been doing for 20 or more years. Mind you for one pass you'd need 5hp perhaps. I've only got 3hp so first option might be best - except only one cheek of tenon would be registered from the face side of the workpiece - it'd be turned over. |

|