|

|

Post by staffie on Feb 1, 2008 9:09:17 GMT

Just found this tip on the Plans Now monthly e-mail

Quick Tip - Essential Squares for the Shop

Drywall Square for Woodworking Drywall Square - Aside from its more obvious use, a drywall square is perfectly suited for woodworking. This tool gives you extra reach for working with plywood and other large sheet goods. Some drywall squares are adjustable, like the one in the photo at left, and have a protractor for drawing angles. They also work nice for drawing dado lines across facing work pieces, like in a bookcase or shelf project.

In my opinion a drywall square is not accurate enough, what do you think?

|

|

|

|

Post by jfc on Feb 1, 2008 23:08:57 GMT

No chance ! That pie fatty puss fella sorted this out a million years ago with 3, 4, 5 . A square is the last thing to use when squaring units etc .

|

|

|

|

Post by sainty on Feb 2, 2008 10:50:49 GMT

Horses for courses I suppose. I've tried to use a drywall square for sizing panels out of a 8x4 sheet and it wasn't anywhere near accurate enough for me (b&q drywall square mind). The old 345 method is the way forward I'm afraid. Last time i used 3 rips of MDF and made my own square, wouldn't recommend it though! In hind sight it probably be better to spend some time making it out of one piece of ply/MDF and keeping it in a safe place.

|

|

|

|

Post by engineerone on Feb 2, 2008 11:04:27 GMT

interesting thread. in that all squares have the potential to be innaccurate. the biggest problem with a dry wall type square is how you accurately set it against the edge of the sheet goods you are trying to square. (one answer is the add on from veritas, which screws against one leg, and allows you to relatively accurately set the square over the edge of the sheet) firstly, you have to be sure the square is true both ways. if it does not have some kind of stop, like a conventional square then you are relying on feel to ensure you have it properly aligned. the other problem is it is pretty easy to knock one of the arms out of square because of the sizes. i have a brass folding 345 square which works pretty well for me, and you could always use a roofing square which also has a running edge, the metal ones are decent, but the plastic ones at under a tenner have a lot to offer. the biggest point about getting an accurate 345 is that it depends on an accurate pivot point. check out the method recommended by scrit to cut squarely on a table saw with 5 cuts. don't know the link though paul  |

|

|

|

Post by thatsnotafestool on Feb 2, 2008 12:37:07 GMT

Getting it square over a longish (say tall kitchen cabinet length) is really tricky, I find. Almost akin to trying to cut two sides parallel over that sort of distance. 345 works but if you're making lots of these sort of cuts then it's longwinded and I haven't yet found the answer.

For smaller squares, I'm tempted to buy one of those ultra accurate Incra squares and then ONLY use it when I go to a local tool shop to test out their squares to get the most accurate one. And that's the square I will use, leaving the Incra safely wrapped up as a reference to be used the next time I shop.

I reckon you need an approach like this based on experience in a local Worcester tool shop. I'd gone through their entire stock of squares trying to find two that lined up with each other and so give me a fighting chance of them being square. None of them did. I took a few to the counter and said to the bloke that they weren't square and did he have anymore. Pausing to pick up his knuckles from where they had been trailing along the floor, he grunted which I took to mean 'No'. I asked him what he wanted me to do with the do :odgy square. "Stick 'em back up on the board,would you?"

|

|

|

|

Post by johnboy on Feb 3, 2008 6:55:15 GMT

For smaller squares (up to 8") I use steel engineering squares. They are made to a british standard and are very robust so difficult to knock out of square. Don't see any need to splash out on expensive Veritas stuff. For cabinets etc I just check the diagonals.

John

|

|

|

|

Post by jfc on Feb 3, 2008 9:11:01 GMT

Yup a pinch rod makes it quick and easy to check the diagonals . ( a bit of wood with a nail in the end )

|

|

niki

New Member

Posts: 38

|

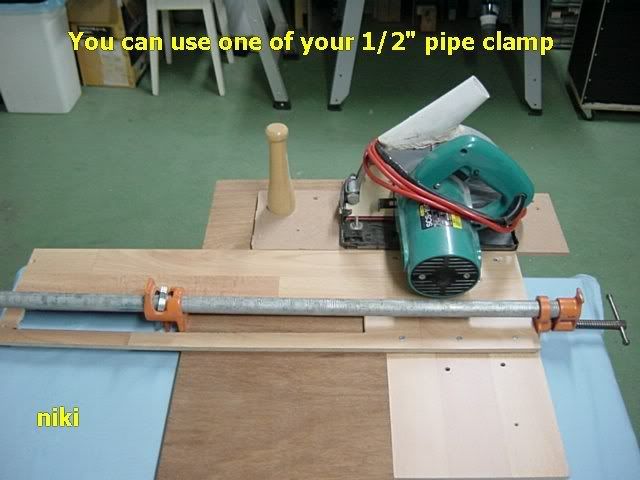

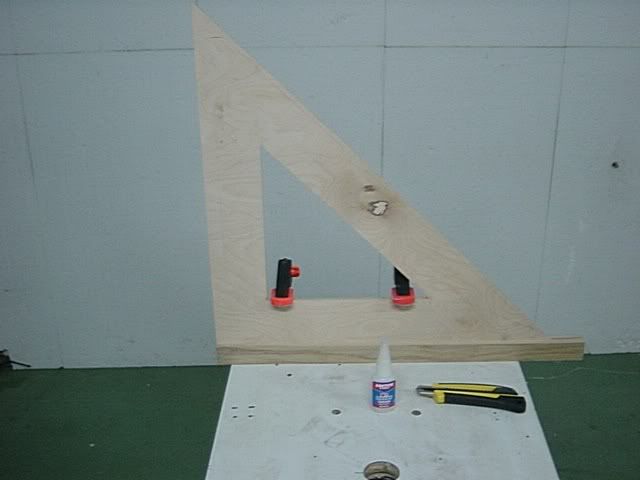

Post by niki on Feb 3, 2008 16:58:32 GMT

This square, is called "framing square" and even though you can adjust it very close or even dead 90°, I don't think that you can square it from all sides unless the width of both legs is very, very consistent all along...that usually, it's not.... For a jobs like cutting man-made boards, I use the "T sawBoard", made at the same method that I made the "T square"...   Or the big "Copy and Past" triangle that I added a fence to one side...  niki |

|