|

|

Post by paulchapman on Jan 13, 2009 19:32:25 GMT

your average woodworker (such as me) will only really need one two-sided stone for all general purposes. I think that's the crux of the matter, Jacob. A lot of us are not doing "general purpose" woodwork, or working predominantly in softwood. When you are attempting to do fine cabinetmaking, using very hard woods, often with difficult grain, then you need something a bit better than a quick rub of your blade on the doorstep ;D Cheers  Paul |

|

|

|

Post by mrgrimsdale on Jan 13, 2009 20:01:23 GMT

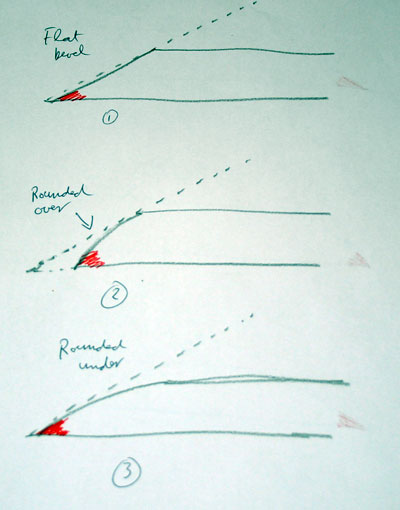

your average woodworker (such as me) will only really need one two-sided stone for all general purposes. I think that's the crux of the matter, Jacob. A lot of us are not doing "general purpose" woodwork, or working predominantly in softwood. When you are attempting to do fine cabinetmaking, using very hard woods, often with difficult grain, then you need something a bit better than a quick rub of your blade on the doorstep ;D Cheers  Paul No you can go as sharp as you like with as fine a stone as you want, with convex bevel sharpening, quicker and easier than using a jig. That's the whole point - the crux of the matter. It's not a quick rub etc it's a careful, systematic approach, but quick an easy . Very rough sketch follows: dotted line represents 30 degrees, red the sharp edge fig 1 shows flat bevel, 30 degree edge fig 2 shows rounded over bevel - more than 30 degree edge - to be avoided fig 3 shows rounded under bevel - 30 degree edge just like fig 1 but falls away to lower angle.  |

|

|

|

Post by paulchapman on Jan 13, 2009 21:10:07 GMT

Thanks for taking the trouble to do the drawing, Jacob. I'm struggling to see any advantage as far as the honed edge is concerned. There may be some advantage in speed once you have the knack I suppose  If I were to hone freehand (which I don't) I think I would go for hollow grinding the blades, which then gives you two edges to rest on the stone and you carry on like that until the hollow is removed and you re-grind. For me, honing is about repeatability and guaranteeing a razor-sharp edge. Honing guides give me that and, despite what you say, don't take much longer than free-hand honing - and arguably they are quicker in that they can give you a better edge so, long-term, result in less faffing about. Each to their own  Cheers  Paul |

|

|

|

Post by engineerone on Jan 13, 2009 22:39:32 GMT

will repeat the mantra. if you look at really old chisels they are likely to have jacob's rounded bevel. why?? simple if you rely on your hands being able to be locked in one place, by definition you are going to sharpen in a rounded bevel way, because you only have one edge on which to rest. where as if you use a guide you are more easily able to steady the blade and keep a consistent angle which does what you need at the sharp end. however honing a secondary bevel is not too far from what jacob proposes. the important thing is to have a flat face on the opposite side to the bevel. there are some who have managed by practice to be able to freehand sharpen and hone without producing a rounded bevel, but having inspected a number of older chisels, i am certain that the only reason for a rounded bevel is that it is difficult to keep your hands and wrists properly stable all the time. many people suggest that the best way to get a stable base is to use a grinding wheel so you end up with two edges to the bevel, so it is easier to keep it stable. however at the end of the day, if you are happy with the results of your sharpening, good, if not don't moan about the way in which others do it. paul  paul |

|

|

|

Post by mrgrimsdale on Jan 13, 2009 23:02:35 GMT

I forgot to say - the rounded bevel in sketch 3 is generally recommended for mortice chisels, though I'm not sure why just them in particular. That's what set me off looking at doing the same with other chisels and plane blades.

|

|

|

|

Post by paulchapman on Jan 13, 2009 23:16:31 GMT

I forgot to say - the rounded bevel in sketch 3 is generally recommended for mortice chisels, though I'm not sure why just them in particular. The most common reason seems to be that some people say it makes scooping the chips from the bottom of the mortice easier. However, I find that a rounded bevel on mortice chisels makes it more difficult to drive the chisel into the wood and more difficult to keep the cut upright. As long as the methods you use work well for the type of work you do, it doesn't really matter what methods you use. Nevertheless, it's interesting to see the differences in the way people approach the same problems. Cheers  Paul |

|

|

|

Post by thebloke on Jan 14, 2009 10:26:01 GMT

Blimey...what's gone wrong? This thread's remarkably civil...just waiting here for teddy to get thrown out the pram ;D - Rob

|

|

|

|

Post by nickw on Jan 14, 2009 10:28:56 GMT

I'd have said that the difference between 2 and 3 is that 2 is a 45deg edge and 3 is a 30 deg edge, or thereabouts.

|

|

|

|

Post by mrgrimsdale on Jan 14, 2009 11:16:14 GMT

Blimey...what's gone wrong? This thread's remarkably civil...just waiting here for teddy to get thrown out the pram ;D - Rob Matron has been round with the pills ;D I'd have said that the difference between 2 and 3 is that 2 is a 45deg edge and 3 is a 30 deg edge, or thereabouts. 2 is supposed to represent what you get with careless sharpening when you lift the angle to get a wire edge sooner i.e gradually increasing angle. 3 is sposed to represent how you keep the 30 degree angle by dipping the handle as you go - and incidentally create rounded bevel. I'm a bit mystified by PaulCs comments rounded bevel on mortice chisels makes it more difficult to drive the chisel into the wood and more difficult to keep the cut upright as I can't see what difference rounded or flat would make, given the same cutting edge angle. If anything the rounded under bevel would make it easier as there is less metal to force into the wood. It's not about bevel anyway - it's about quick and easy sharpening. |

|

|

|

Post by paulchapman on Jan 14, 2009 11:24:56 GMT

I'm a bit mystified by PaulCs comments rounded bevel on mortice chisels makes it more difficult to drive the chisel into the wood and more difficult to keep the cut upright as I can't see what difference rounded or flat would make, given the same cutting edge angle. Following an earlier thread on the same subject, I tried it out using some second-hand pig stickers I'd bought and which were honed in the way you advocate, and my comments were based on those tests. Even if the edge is just as sharp as with a flat bevel, the shape of the chisel immediately after the edge causes the problems I described. But, as I said, if it works for you, that's fine  Cheers  Paul |

|

|

|

Post by mrgrimsdale on Jan 18, 2009 12:37:21 GMT

Bin over there again  Some poor sod struggling with sharpening, basically suffering with too much kit and too much information, not knowing that sharpening should be quite easyApparently one popular method involves 'many micro-bevels'. I guess these have to be applied one after the other - I haven't seen the dvd. It occurred to me that my method also involves many micro-bevels; so many in fact that they merge together into one rounded bevel - with the enormous advantage that you can apply them all in one easy movement! Thought I'd point this out as many people seem confused by the convex bevel; if you just think of it as a lot of micro bevels it might make it easier to understand. ;D |

|

|

|

Post by paulchapman on Jan 18, 2009 12:52:16 GMT

|

|

tommo

New Member

Posts: 29

|

Post by tommo on Jan 18, 2009 15:09:21 GMT

Excellent emoticon "Mr Grimsdale..Mr Grimsdale they tried to kill

dear old Nellie"

Regards Tom

|

|

|

|

Post by mrgrimsdale on Jan 18, 2009 15:19:59 GMT

Nope it ain't daid yet by a long chalk ;D ;D

|

|