|

|

Post by gazza on Oct 19, 2007 19:30:40 GMT

Hi all, I am eventually going to get round to making a proper router table, as i have been putting up with an early charnwood bench top one for too many years  The base is no problem, 3/4" ply or mdf I have looked at the cmt top from axminster made from 12mm phenolic but it costs a fortune  I then found this www.directplasticsonline.co.uk/home.php?cat=4814I was wondering if anyone has any experience of this material i.e, can it be cut on the tablesaw, shaped and grooved with a router. I am assuming that tufnol is the same as phenolic ? Cheers, Gazza. |

|

|

|

Post by modernist on Oct 19, 2007 20:00:30 GMT

I thought tufnol was phenolic resin reinforced with fabric plies but I may be wrong. I think it machines OK on all normal processes

|

|

noel

Junior Member

Posts: 52

|

Post by noel on Oct 19, 2007 21:01:31 GMT

I thought tufnol was phenolic resin reinforced with fabric plies but I may be wrong. I think it machines OK on all normal processes I'm pretty sure I've used it. Should cut ok on a TS but try and use a blade with off set teeth so as not to build up too much heat and watch your feed rate for similar reasons. |

|

|

|

Post by engineerone on Oct 19, 2007 22:15:20 GMT

isn't tufnol more of a laminated product like mdf, ?? paul  |

|

pewe

New Member

Posts: 49

|

Post by pewe on Oct 19, 2007 22:16:38 GMT

I have used this stuff quite a bit and this is what I found.

It will cut on a table saw, and it will route, but be careful.

This materieal is a paper based phenolic, and it is used in the electical industry because of its conductive and heat insulation properties. As such it does not dissapate heat quickly which means it burns very easily if not cut slowly and fed at a slower speed than wood.

It needs a very sharp cutting edge and will blunt the cutting edge very quickly.

Also when cutting the edges can chip just as easily as melamine - so can look a bit unsightly.

The dust created is very fine and just as 'lethal' - if not worse - than MDF - so use a good mask abd dust collection equipment.

For a router table you need to use at least 25mm thick material to minimise bowing under the weight of a router. Anything thinner, such as the 20mm, and I've found that it needs to be strengthened if larger than 500mm square.

|

|

|

|

Post by Scrit on Oct 20, 2007 5:02:58 GMT

I have looked at the cmt top from axminster made from 12mm phenolic but it costs a fortune  I then found this www.directplasticsonline.co.uk/home.php?cat=4814I was wondering if anyone has any experience of this material i.e, can it be cut on the tablesaw, shaped and grooved with a router. I am assuming that tufnol is the same as phenolic ? Tufnol is a firm ( Tufnol Composites Ltd) based in Birmingham who manufacture a wide range of re-inforced phenolic plastic resin sheets. The lowest grades, which are more than suitable suitable for horizontal worktop use, are paper re-inforced, next are the engineering grades which are linen or even glass-fibre re-inforced and there are some quite esoteric grades which are re-inforced with materials like carbon fibres. Look "Hoover" the name "Tufnol" has become synonymous with phenolic resins in the UK, although they tend to guard their name and reputation somewhat jealously. All I can say is that Tufnol is probably the best phenolic resiin you'll get hold off in this country. The material saws well with a fine-tooth blade (ATB or triple chip), can be routed with standard TCT router cutters (although reduced spindle speed is advisable), and can be drilled and even tapped to hold threads - however for longer-lasting threads I'd suggest epoxy-glueing threaded brass inserts into it. As others have said machine requires care as the material tends to be somewhat "grabby". The rule of thumb is to reduce the spindle speed and increase the feed rate, the intention being to produce chips rather than dust when cutting. Dust, especially when drilling, indicates too slow a eed rate and will result in overheating and tapid dulling of tools. Router cuts should be ectremely shallow (no more than 2 to 3 mm) isn't tufnol more of a laminated product like mdf, ?? It's a thermoset cast plastic resin. MDF is NOT laminated - it's actually heat and pressure formed resin-bonded wood fibres and thus completely different Scrit |

|

|

|

Post by engineerone on Oct 20, 2007 10:11:39 GMT

as usual scrit i bow to your knowledge,  the reason for feeling that mdf is laminated, is that it always kind of "de laminates" if it breaks. paul  |

|

|

|

Post by gazza on Oct 21, 2007 12:55:33 GMT

For a router table you need to use at least 25mm thick material to minimise bowing under the weight of a router. Anything thinner, such as the 20mm, and I've found that it needs to be strengthened if larger than 500mm square. The CMT top is only 12mm thick, according to cmt uk website,why does this not bow, or is it reinforced underneath ? I was considering 15mm thick, but im not so sure now  after reading the us site where the top is 3/4" thick  25mm puts the price up considerably, so perhaps back to the drawing board for this one  unless anyone has any ideas ;D Cheers, Gazza. |

|

|

|

Post by johnboy on Oct 21, 2007 15:40:13 GMT

My router table top is 2 layers of 18mm MDF with a coat of acrylic varnish, doesn't look pretty but is cheap and works fine.

John

|

|

|

|

Post by gazza on Oct 21, 2007 16:25:56 GMT

Cheers John, I have a couple of sheets of 3mm aluminum and was thinking of using that glued to mdf, but i was concerned about bowing unless i use the aluminum on both sides. It would be alot cheaper mind you ;D ;D Decisions, Decisions Eh  Cheers, Gazza. |

|

pewe

New Member

Posts: 49

|

Post by pewe on Oct 21, 2007 16:43:07 GMT

I have a Woodhaven Phenolic top which is about 20mm thick. It is recommended that it be fixed to a solid frame to prevent warping. It is here - www.woodhaven.com/ProductDetail.asp?Id=1554I have a spare one which has never been used - if your interested PM me. |

|

niki

New Member

Posts: 38

|

Post by niki on Oct 21, 2007 17:52:21 GMT

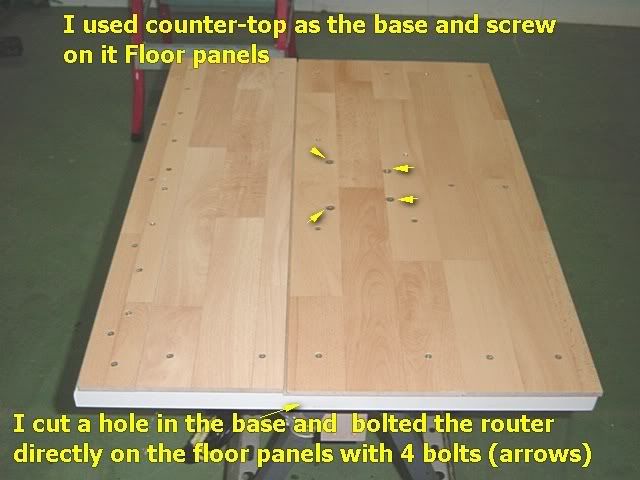

Hi Gazza Just my amateur input... I made the top of 30mm counter top re-enforced by two boards lengthwise. On top of the counter top, I screwed 8mm Floor Panels, The router is bolted to the Floor Panel (Hitachi M8V2) with countersink head bolts (M6). I used floor panels because they are covered with Plastic Laminate from both sides, they are very smooth (slippery) and if I have 15 years guaranty for walking on them, they should be good enough for router table top. I did not make any "insert" but if one day I will, it will be very easy to make the insert from the same floor panel so no height adjustment will be needed. Regards niki   |

|

|

|

Post by cbrsyd on Oct 22, 2007 13:33:25 GMT

|

|

|

|

Post by gazza on Oct 22, 2007 18:00:06 GMT

Nice one Nikki, So thats what that stuff that looks like wood flooring is for ;D ;D Thanks Cbrysd, i will have a butchers later  Cheers, Gazza. |

|