|

|

Post by engineerone on Dec 30, 2007 12:04:24 GMT

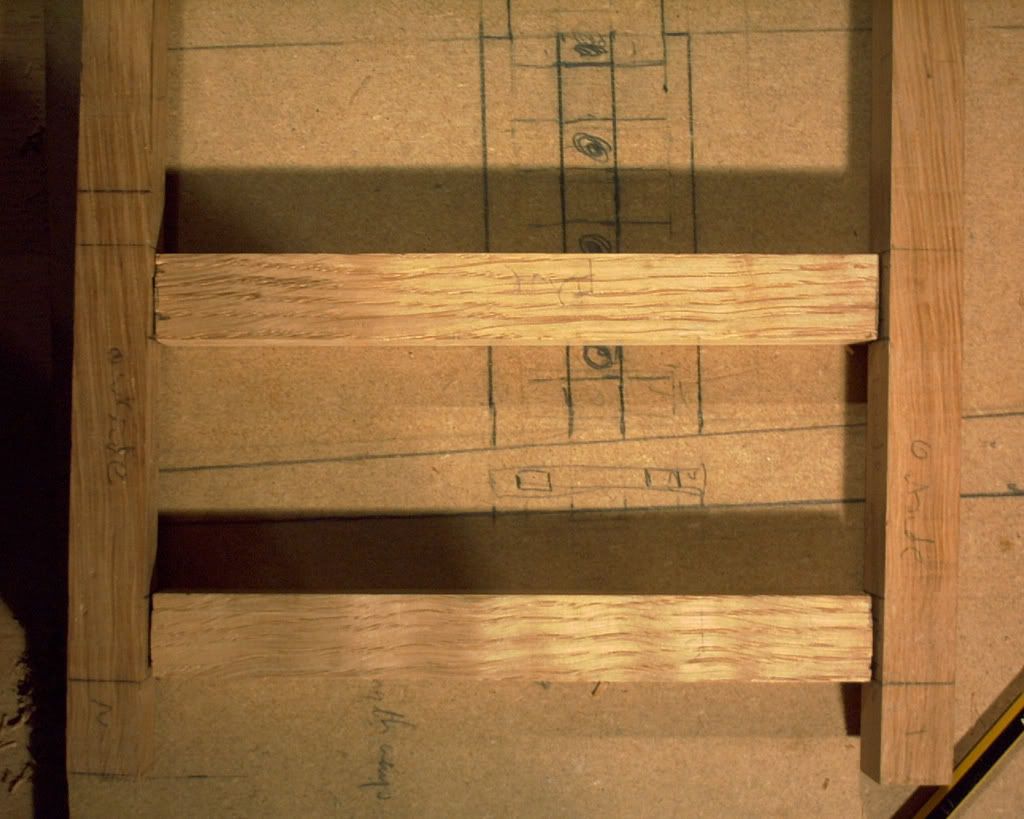

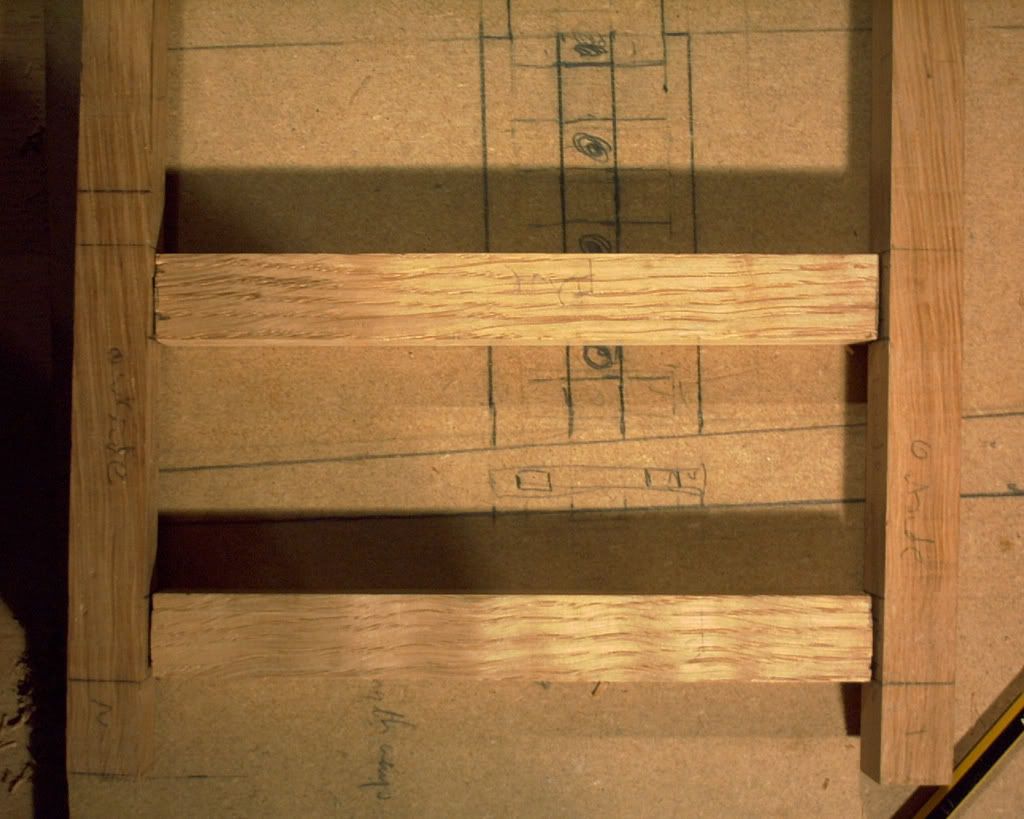

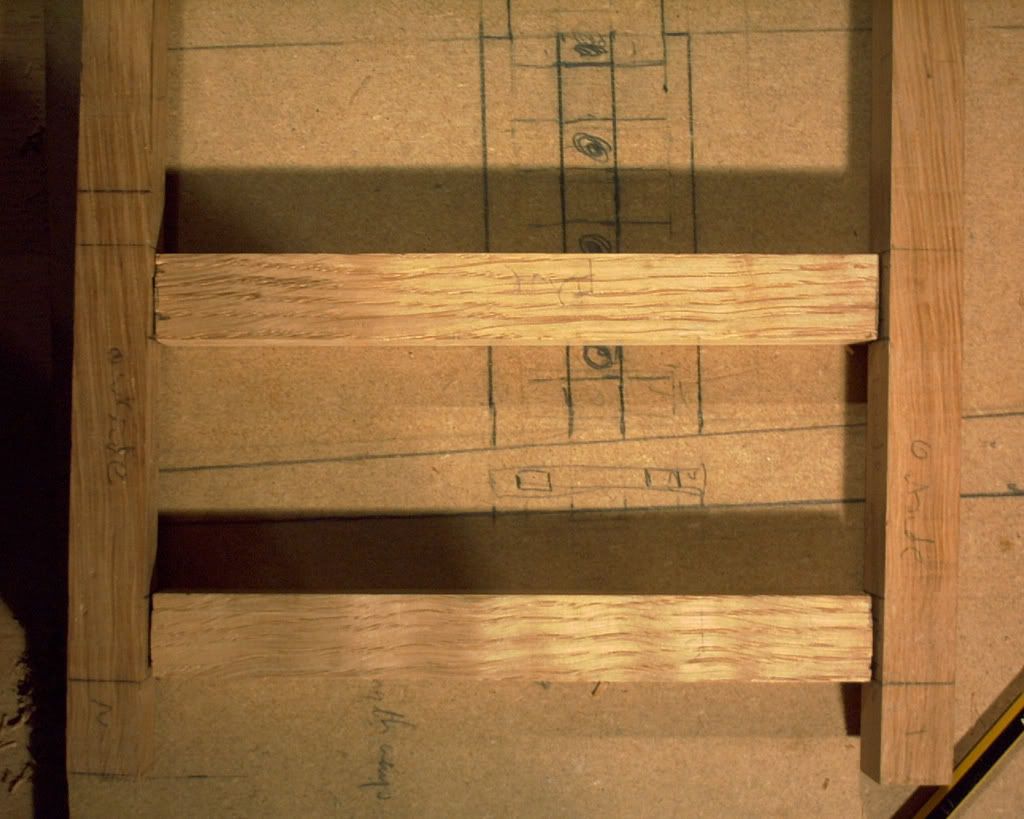

i have been asked to make a small light table for a friend's wife (yes i do have one or two  ) it is quite tall, about 600, with a top that is 250x350 cause it has to fit a specific place. i have kind of based it on a shaker table, but somewhat more modern. i finally made a proper full size layout on a sheet of mdf i have for the purpose, and cut up the various bits. the legs have ended up slightly thinner than i expected, however being in oak, they seem strong enough and colinc reckons it will work, so. hand planed the taper on the legs. and at odd times over xmas have been putting the top rails in one end. this is the end where a small drawer will go, so instead of a solid piece as for the rest of the apron, i have put a top and bottom rail in. to try and ensure it stays together i thought i would be a smart ar*e and use horizontal stopped dovetails. this is not of course normal, but since the top is taller than the apron this was necessary. so my question is how do you cut stopped dovetails in such a small piece, so that you ensure that they end up the same depth from the front as well as parallel. i sawed to the line of the stopped part first and then chiselled out, which is a real pain. then i cut the tails and then adjusted them to fit the sockets. which included cutting back to get the correct depth. the biggest problem at this time is of course holding the legs whilst you cut the socket, and the same applies with the cross bar. so any ideas on a better way by hand?? how do you ensure that things are flat and level??   since i still have the lengthways mortices to finish it is not as pretty as it might be, but does show what i am trying to achieve. this is the first time i have done stopped dovetails by hand. my feeling is that even with my rat it would still be a pita  anyway any further thoughts would be appreciated ;D paul  |

|

|

|

Post by afterglow on Dec 30, 2007 13:17:31 GMT

Paul, I don't quite understand what design you're trying to do - any chance of a quick drawing to show dimensions and what the piece should look like so that I can get to grips with the project a bit better? Keeping things square is the bane of my life in woodworking at the moment, so I really feel for you on this - my little side table had some similar sounding "challenges"  Cheers, Lee |

|

|

|

Post by engineerone on Dec 30, 2007 18:16:18 GMT

gawd lee, i have enough problems loading pictures so drawings too  anyway see whether you can make out the dark lines on this  paul  |

|

|

|

Post by mel on Dec 30, 2007 19:34:42 GMT

paul

you seem to have got yourself in a bit of a pickle

the joint you are trying to use is far to technical for the purpose.

have you been buying those books on japanese wood working tools and joints ;D

or a 4"x10 through the face frame ;D ;D {site joiners }

on a more serious note

a stopped mortice would have done for a small table

once the glue gets it , it wont budge

KISS {keep it simple stupid}

works for me anyway

mel

|

|

|

|

Post by dom on Dec 30, 2007 20:15:49 GMT

Mark up first, then clamp wood at the cutting lines so you have a guide for your chisels.

Or make a jig out of MDF and transfer from one leg to the other.

|

|

|

|

Post by engineerone on Dec 30, 2007 20:25:56 GMT

mel , dom, you are both right, i was being a smart ar*e, but also trying to improve my skill base. mel i was actually concerned about the area twisting when the drawer was moved. i would guess it won't make too much difference on something this small, but ;D you have to start somewhere  i managed to do it quite well really i would suggest, not least because you end up with a 3d problem of levels. the thing is some of the mess at the back will be covered by the m/t'd apron coming from the front to the back. anyway i am trying to improve the hand tools skills and also the ability to see things through, but i do appreciate that the next time round i will use the rat ;D only thing is though it might take almost as long to set up as cutting what i have by hand  paul  |

|

|

|

Post by afterglow on Dec 31, 2007 11:33:42 GMT

so my question is how do you cut stopped dovetails in such a small piece, so that you ensure that they end up the same depth from the front as well as parallel. i sawed to the line of the stopped part first and then chiselled out, which is a real pain. then i cut the tails and then adjusted them to fit the sockets. which included cutting back to get the correct depth. the biggest problem at this time is of course holding the legs whilst you cut the socket, and the same applies with the cross bar. so any ideas on a better way by hand?? how do you ensure that things are flat and level?? I think the main answer to your question is the same answer I hate to hear myself - "Practice!". I think I can see what you're trying to achieve now and so I'll give a few thoughts from my own experiences that have screwed me up royally more than once. 1. Make sure the stock is square. Really square. Face and edge, plus ends of stock must all be 90 degree angles if you want to give yourself a fair chance of a square construction at the end. My side table isn't altogether square and I'm not happy about it! 2. Practice cutting the joint you want to cut on some scrap wood first until you get the hang of cutting it to the depth/length you want it. 3. Use the 'rat to cut the tails on the rails first so that you get them all cut the same. Then mark your sockets on the legs from the tails - at least this way your rails should be the same length. 4. Use sharp chisels. God I used to suffer with bad edges until I got obsessed with sharpening for a while! 5. While you've got the rat out, you can always cut out the waste from the "mortice" part in the legs, working freehand but leaving the last 3-4mm to take out by hand. This way you'll get the depth sorted out too. As you can probably tell, I like using the 'rat when I'm doing joinery! Cheers, Lee P.S. I like stretching myself with joinery too - it's the best way to learn. |

|

|

|

Post by engineerone on Dec 31, 2007 13:46:10 GMT

thanks lee, that is kind of what i was looking at however what does worry me now is how fragile thin oak is  so what better woods are there for thin work. it seems very friable when only 4 mm thick, so i am hoping it won't break in the joint  i will next time use the rat i am sure when i am doing both m/t's and dovetails. mind you need to practice there too ;D paul  |

|

|

|

Post by 9fingers on Dec 31, 2007 14:24:43 GMT

however what does worry me now is how fragile thin oak is  so what better woods are there for thin work. it seems very friable when only 4 mm thick, so i am hoping it won't break in the joint  paul  Hey Paul, have you been watching me this morning or what?? I've just been edge trimming some 12mm ply cupboards with U channel oak 4mm in each limb and 4mm groove slipping onto a tongue on the ply and yes it splits very easily!! Bob |

|

|

|

Post by afterglow on Dec 31, 2007 14:30:05 GMT

4mm is hellish thin for a table joint, Paul. It sounds to me like you're building an anorexic table  Oak is generally a very strong wood but it's not fine-grained, compared to something like cherry or mahogany. As a result, you rarely see it used in small sections because it doesn't take fine detail very well (like the lumps that fell out of some turning practice I did once!). What section are the legs where the rails join? I'd want to have half-inch thick joinery for a table, I think, maybe 10mm at the lightest. 4mm is not woodwork, it's origami  Cheers! Lee - off to the workshop when my 6yr old lets me escape playing with the Wii... |

|

|

|

Post by mrgrimsdale on Dec 31, 2007 15:26:51 GMT

snip friend's wife (yes i do have one or two) What, you chat them up with offers of little tables? ;D Anyway it looks like you are getting the rod habit, which can't be bad. When you get the hang of it you find that you only need to draw horizontal and vertical sections, not the whole plan or elevation. As for design details I'd stick firmly to Aunty Joyce *, who gives all the standard solutions to most things. One thing about woodwork which a lot of people can't accept is that it isn't a creative process at all. It's more a question of learning and applying well established and traditional techniques. Don't try and work it out for yourself - Aunty definitely knows best. Old Jim Krenov has misled a lot of woodworkers over the years, with his "creative" fumblings ;D cheers & happy new year Jacob *"aunty" thanks to jfc ;D |

|

|

|

Post by Alf on Jan 1, 2008 9:34:15 GMT

Paul, one suggestion for next time - joints first, tapering legs second. Removes one more complication. And Lee's right; oak can be hellish in small section so I sympathise.  Cheers, Alf |

|

|

|

Post by engineerone on Jan 1, 2008 19:45:17 GMT

back after the night of revellry. just a couple of thanks and thoughts. yes it is an anorexic table, and of course one always chats up the customer's wife to ensure you get the best work at a decent price ;D alf you are right and next time i will do the taper second however part of the learning process is that fear of screwing up  you know if i have cut all the joints and then screw up the taper, or i do the taper and then screw up the joints  still so far not too bad, one reason for the oak is i have never used cherry so far, and although i have some i wanted to check out the process. i had lots of offies of oak, and was able to think about wasting it a little. lots left over after the last table. for interest the legs are about 17mm square, and they are in fact square at the top  and the apron parts are 11mm thick, so using the basic premise therefore the tenons are about 4mm thick and 10 deep. i will however do a belt and braces method to ensure that the frame stays tight since i want to put a top on the drawer part as the very top is kind of floating above. this will allow me to try and make the leg assembly pretty solid and stable for such an anorexic piece ;D jacob, i understand what you say, but do feel you are a little wrong about inventing ways to do things. not least since this is a learning and production process. as for the rod the whole point is to visualise what you are doing so the complete drawing so far makes sense to me. if this works, i will then make one in cherry and make it somewhat more simple. interesting though so far no ideas about doing the stopped dovetails  paul  |

|

|

|

Post by mrgrimsdale on Jan 1, 2008 20:16:05 GMT

snip alf you are right and next time i will do the taper second however part of the learning process is that fear of screwing up  you know if i have cut all the joints and then screw up the taper, or i do the taper and then screw up the joints  The general rule is that you keep everything in the square as long as possible so that you retain your reference surfaces for machining, holding, marking, morticing etc. So you'd definitely do your tapers last.Aha got it! Easy mistake to make; the thirds rule of thumb means that mortices shouldn't be much more then 1/3 of the width (but can be a lot smaller if wanted) but tenons shouldn't be less than 1/3 but can be more - up to full thickness if wanted. So in your case you could have 17/3 mortices (6mm OK) and 6mm tenons to matchAs long as you also ask yourself why things are traditionally done in certain ways as per aunty Rod - you do as much or as little as you need. Fully detailed drawing is fine, but with practice it gets reduced down to the minimum of necessary marks, and may be meaningless to an onlooker, or to yourself if you have to come back to a job after a week or so.  See Aunty for stopped dovetails and drawer rails esp pages 272, 273, 329 and other places cheers Jacob |

|

|

|

Post by engineerone on Jan 1, 2008 20:19:10 GMT

interesting but for the moment too late, jacob,i had thought and i guess so had many others that the tenon was 1/3 of the width of the tenon part, not the mortice part  paul  |

|

|

|

Post by afterglow on Jan 3, 2008 9:11:03 GMT

Paul, You're clearly not getting the answers you want  So I went hunting back through your original post and spotted The first part is pretty easy - assuming you haven't assembled any of the table anyway. If you're working with the leg, just clamp it to the bench and cut straight down into it. If the taper stops it being level, cut a wedge from scrapwood (or use the piece you cut off) and clamp that underneath it to hold it level. For the rails, hold upright in the vice to cut down with a dovetail saw and then use a bench-hook to hold it for the cross-cuts. Personally I always use the Woodrat to cut tails because it does such a great job of it and it's really quick and easy. Once you've got the rails cut, mark the depth and length of the tails on the legs by transferring these dimensions using a marking/cutting gauge. Once these are set, mark along the line of your tails to get the angles right. Incidentally, your pencil isn't sharp enough for this kind of joinery! The pencil line is 1mm wide or more and that's enough to make a 2mm gap all around your joint if you cut the line away. That's why you see so many cabinetmakers using cutting marking tools (knives, gauges and pins). A cut line also is a great way to register your chisel bang on for the careful final paring to the line. As far as the flat and level bit goes, it comes down to practice. Using a square piece of scrap stock to hold the back of your chisel against for the final paring cuts is one way I've seen recommended. I'm sure the pros on the board here will come up with others though. And of course you can always check it out in a book or have a hunt on the web for it too. Cheers, Lee |

|

|

|

Post by Alf on Jan 3, 2008 9:36:21 GMT

Using a square piece of scrap stock to hold the back of your chisel against for the final paring cuts is one way I've seen recommended. Works very well; with appropriately cut blocks works for angles too. In addition to the fineness of the line, using a knife, gauge etc gives a positive line to register your chisel in for such a method as well. Well it does for whatever method you use. (I'll go away and state the bleedin' obvious somewhere else in a minute, hang on  ) Potentially a little bit of heresy here, but a file can do wonders for cleaning up a joint if you find paring is difficult 'cos of unhelpful grain. i.e. a fine paring cut goes haring down with the grain instead of the fine trimming you were aiming for. Particularly thinking of the fine fitting of the male dovetail part. Cheers, Alf |

|

|

|

Post by dom on Jan 3, 2008 17:39:18 GMT

Does nobody read my posts, that's what I said right at the start  |

|

|

|

Post by dirtydeeds on Jan 3, 2008 18:10:07 GMT

sorry dom, we've clearly all forgotten your valuable imput  |

|

|

|

Post by engineerone on Jan 3, 2008 18:47:05 GMT

of course we read them dom, then we do a jason ;D and ignore them ;D no actually everybody has glossed over the original question, but i have now done the first two legs and aprons and dovetails, now only the back legs  seems ok so far, need to check it out when assembled to see if it will be as solid as colin and i think it might. paul  |

|

|

|

Post by Alf on Jan 4, 2008 9:09:11 GMT

Does nobody read my posts, that's what I said right at the start  your posts? We're supposed to read them? Did I miss a memo? Probably I didn't read it... ;D Sorry, Dom.  Cheers, Alf |

|

|

|

Post by engineerone on Jan 24, 2008 23:19:58 GMT

i am still working on this anorexic table. not as much time as i hoped, but.  i finally succumbed to machine work cause i was not too happy with the joint lines with the tenons on the cross rails, so i re did them on the woodrat  this of course means that the distances are smaller than the original rod i used. i then had to re-cut the dovetail cross rails at the front, still they seem ok now, and the problems can be camouflaged. now i am working on the lower rails and cross rails which will make a shelf. this involves m/ts for the cross rails, then slotting the long rails to drop in, and they will be dowelled. colin has seen it so far, and thanks to him, i feel confident about moving forward, but here's the question. if after making the rod, the finished sizes of your pieces are smaller than those in the rod, how do you set up the dimensions??? in this case for instance the legs are thinner than original, and now narrower, so the lower cross rails will of course be narrower,. and of course the angles may not be exactly the same. so how do you pros' go on after you have done the original design, and the "fudge" the differences. one of the problems with working on your own is you get too involved, and can't necessarily see the wood for the trees, plus of course you want it to be perfect  and your joints are never as good as you would like. paul  |

|

|

|

Post by mrgrimsdale on Jan 25, 2008 10:10:07 GMT

If it's not easy to adjust 'on the hoof' just alter the rod to suit. Rub out lines; draw new ones.

NB I seem to recall tapered legs. Might have been easier to do the mortices first, before tapering. As a rule, all mortices, and tenon cheeks and haunches, are best done first, before any tapering, rebating, moulding, slotting, grooving etc whilst the stuff is still in the square.

cheers

Jacob

|

|

|

|

Post by engineerone on Feb 2, 2008 11:49:16 GMT

ok so have moved forward somewhat, albiet slooooooowly managed to assemble the basic underframe, and get the legs to be level on the bottom as well as the top. the pictures show it with the top and its connections just rested on, and obviously not finished, whilst the lower shelf is not yet fixed either, still trying to figure the spacing of the slats. have to install a top to the drawer box, and make the drawer, the front of which will be oak, and overlap a little. not sure whether to have an infill between the slat rails, or just put ends on. anyway at least i am getting there. wish i had the same pressures as craig to finish things ;D    the pictures of course belie its size, 600 high x300 wide top x 280 the leg unit is 240x 190, and the top will kind of float. it is in oak, and will be clear acrylic varnished with some soft wax. so problems, hand cutting m/t's in thin oak is a major problem, so i used the rat for the tenons, which made the leg unit a little smaller, but more accurate and easier. kind of messed up the rod though. it is ungainly when trying to assemble, and you have to do a number of dry runs to get the measure ments for the slats right, (setting up the rat for multiple pieces can be more difficult than i had remembered   ) and that was just upright cutting the tenons on the end of the slats. ;D next problems then are a sensible way to fit the top to the top cross rails without going from the top down. the cross rails will be recessed into the drawer box sides by about 25mm, so the top will acually be about 10-15mm above the top of the legs. drawer will be made of cedar with the front in the a piece of oak cut from the same piece that is the apron sides. i used the old trick of cutting them continuously along a long board, so the grain basically follows around the sides. (must learn to take better photos  ) hope you like the progress report. paul  |

|

|

|

Post by Lord Nibbo on Feb 2, 2008 16:38:32 GMT

Now that is really nice, I really like it, I'm not saying that to be polite I really do like it. It is quite different to most tall tables you see being made.  |

|

)

)

)

)

and the apron parts are 11mm thick, so using the basic premise therefore the tenons are about 4mm thick and 10 deep. i will however do a belt and braces method to ensure that the frame stays tight since i want to put a top on the drawer part as the very top is kind of floating above. this will allow me to try and make the leg assembly pretty solid and stable for such an anorexic piece ;D

and the apron parts are 11mm thick, so using the basic premise therefore the tenons are about 4mm thick and 10 deep. i will however do a belt and braces method to ensure that the frame stays tight since i want to put a top on the drawer part as the very top is kind of floating above. this will allow me to try and make the leg assembly pretty solid and stable for such an anorexic piece ;D