niki

New Member

Posts: 38

|

Post by niki on Oct 31, 2007 19:32:22 GMT

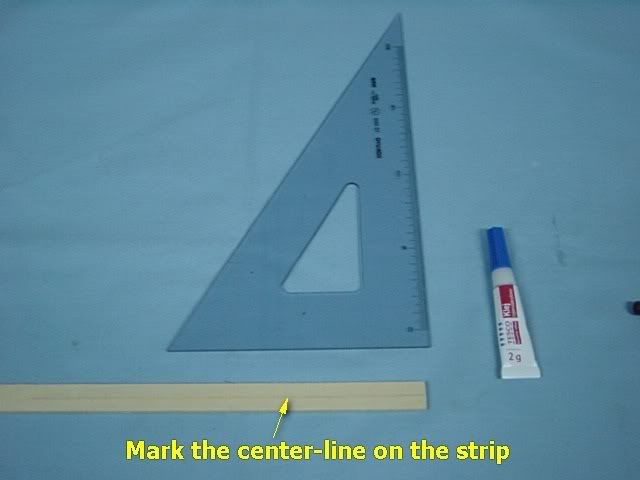

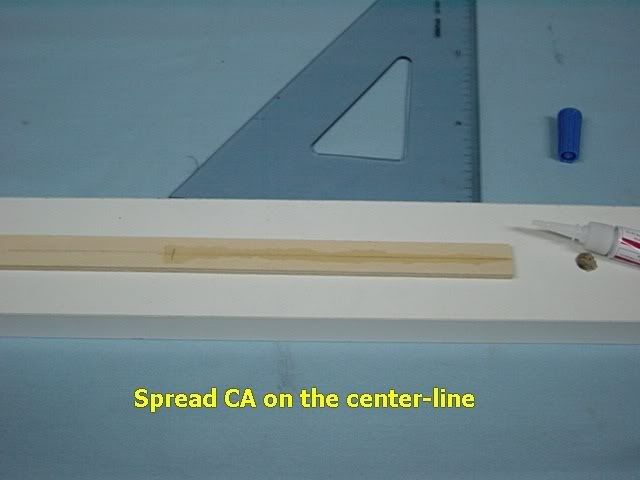

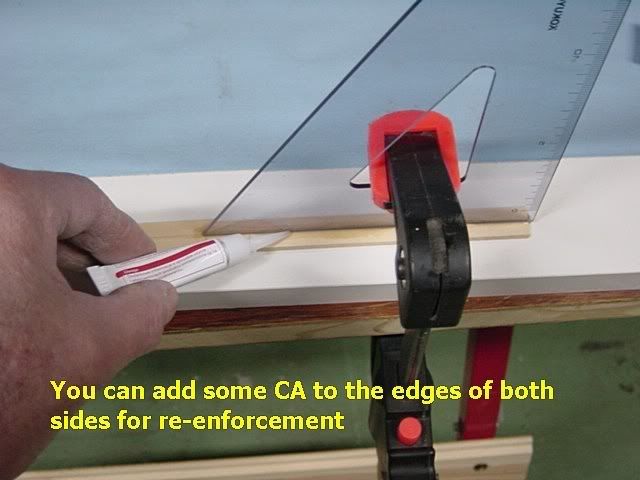

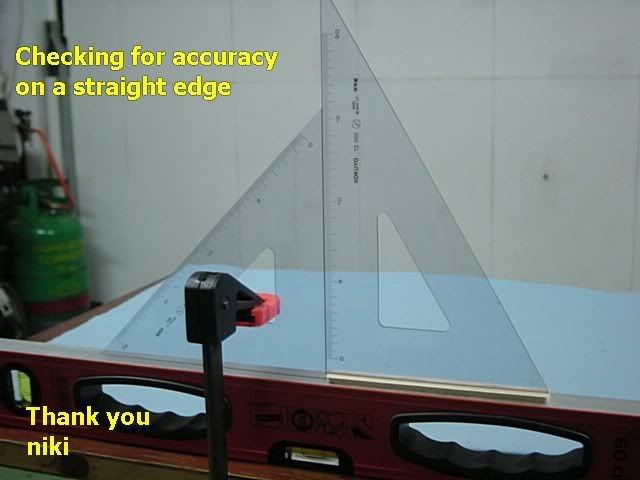

Good day I don't know how this tool is called so, I called it "marking square"...maybe somebody will correct me... I found those plastic drawing triangles very, very accurate so, instead of buying one of those metal marking triangles..that are changing "moods" according to the season (and from checking them in the shops - not so accurate), I made them from more stable materials like plywood or plastic. For the base, you can use any man-made board like, plywood, MDF or even "floor panels" because they have very consistent thickness. Usually, I use 8 mm floor panels [the Formica "loves" CA (super-glue)], for the big triangles but, for that one on the pics that is 2mm thick, I used 4 mm plywood After the modification, you can still use the triangle to check for squareness. And the rest is very simple... Regards niki        |

|

|

|

Post by mrspanton on Oct 31, 2007 21:51:19 GMT

No offense, but I cant see what they can be used for? I have 2 swanson's 1 large 1 small, excellent tool, a square and sliding bevel in one, they get used all the time, they dont break or alter there angle if you drop them, but your ones look a bit fragile? I use a framing square for to do bigger right angles, thats about it. Isnt the uneven trail of glue going to mess up your acurracy anyway and defeat the object. Mind you my 3 year old wants a few learner tools, a speed square made of a plywood triangle in a groove routed in a beech edge would work well. He wants an axe and a billhook as well and a rake and a brace and bit..... ;D? cheers Jonathan  |

|

niki

New Member

Posts: 38

|

Post by niki on Nov 1, 2007 8:04:14 GMT

Hi Jonathan

Well, they are used for marking but they cost much less than the swanson's 10 Pounds ones...normally, I use 90° marking and seldom 45° but almost never in-between angles.

I have two framing squares but I could not achieve perfect 90° from both sides because the legs are not consistent in width so, I can adjust it to be perfect square only from one side and I would not use them for "fine woodworking"...

The last time that I did try to break a CA glued pieces, I had to pull very hard and it ended breaking parts of the plywood (or wood) layers but not on the glue-line...and it was not easy to break.

Usually, all the CA is absorbed by the wood leaving flat area but in this case of the plastic, I just scrape it with a knife, if needed.

I made one with routed groove but I did not get good results, looks like the wood is "working" so I went to the more stable material and simpler method.

Regards

niki

|

|